We develop the best solution tailored to the customers needs, either independently or based on the provided customer design

Over time, Agrati has also specialized in the production of nuts.

Nearly 2 million nuts are produced each month, and over the years, all stages of the process have been perfected, from design to shipment, in order to ensure increasingly high standards of quality and safety, resulting in zero defects in the product.

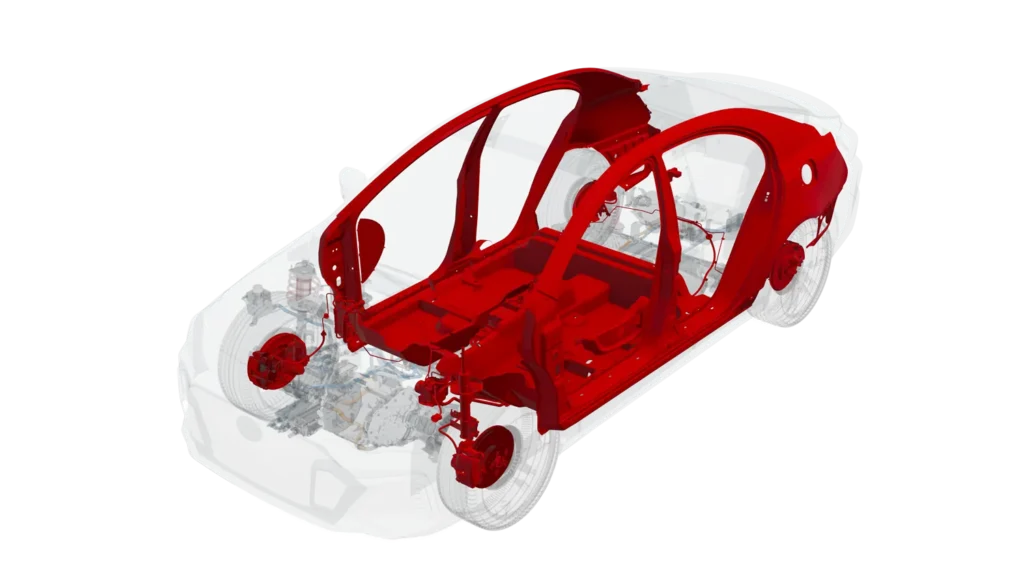

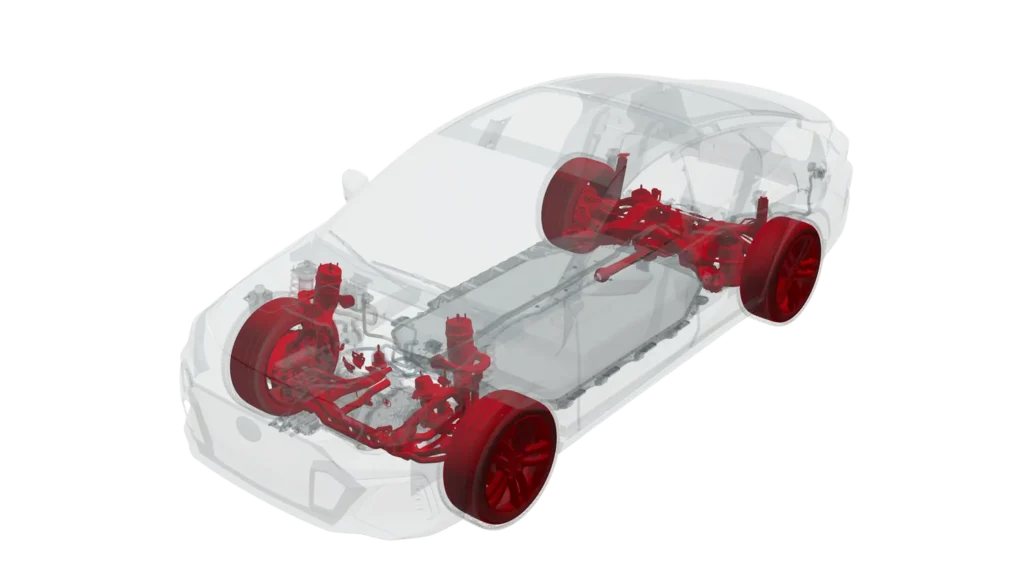

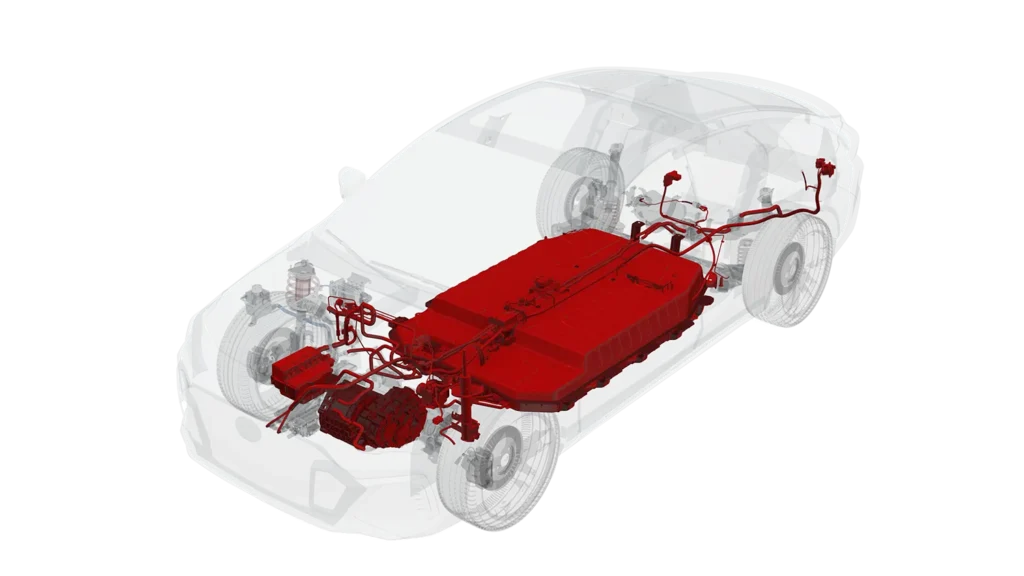

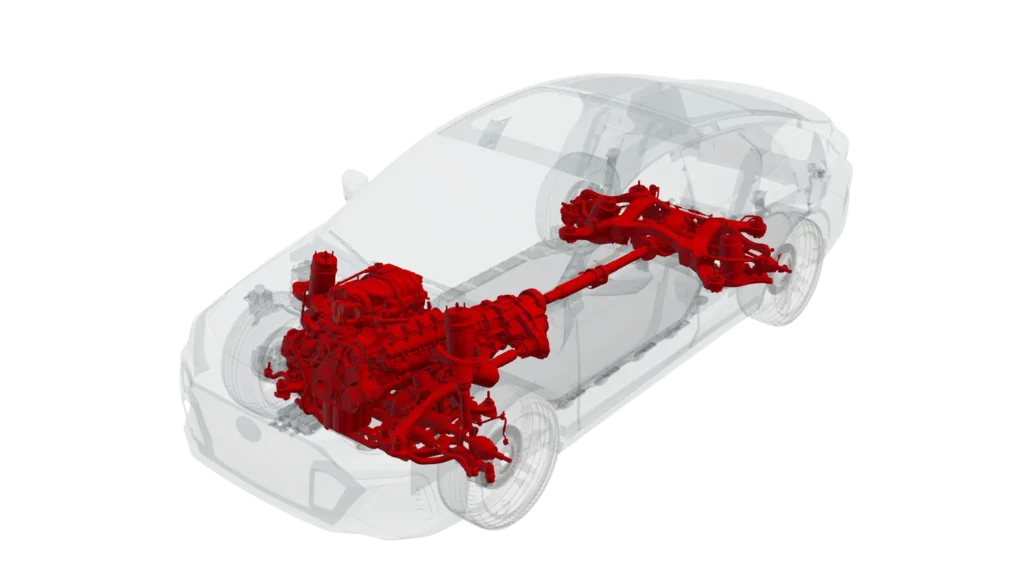

Engineered components used in several automotive applications

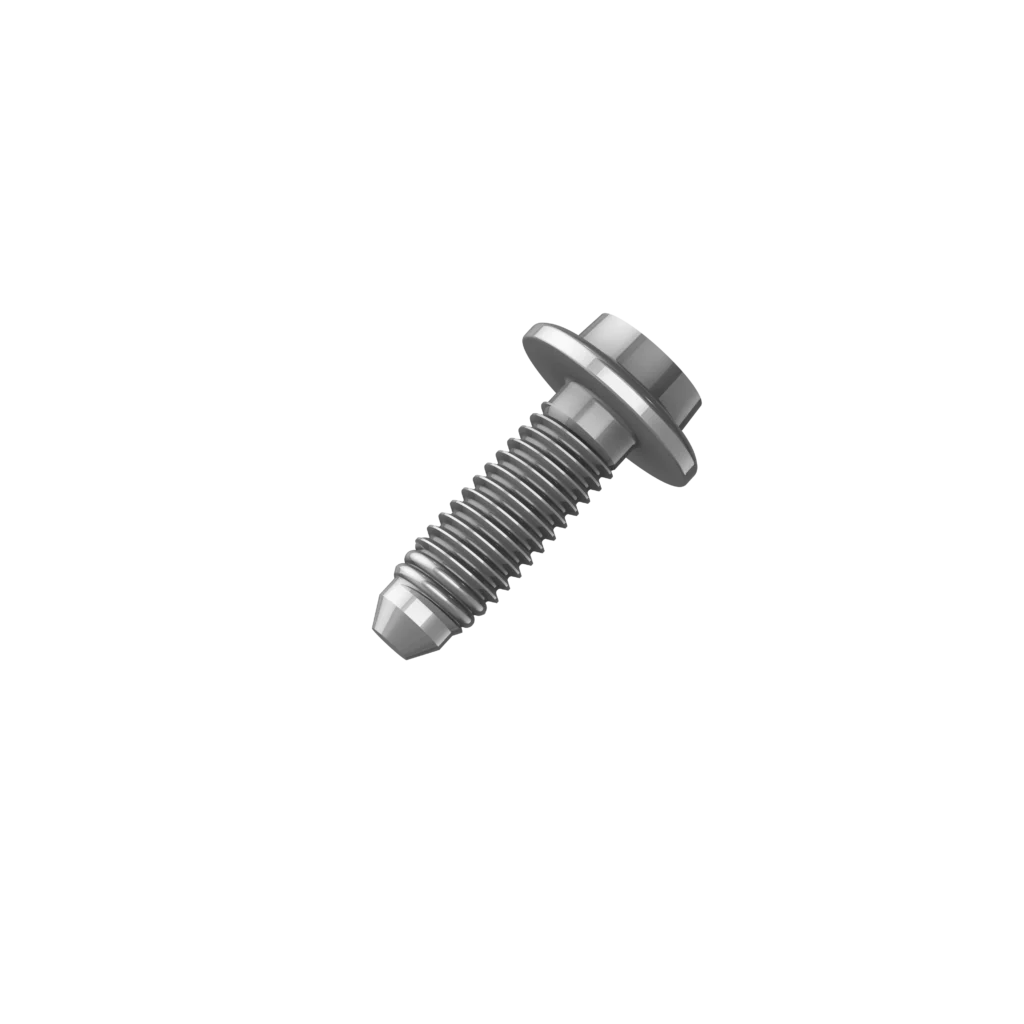

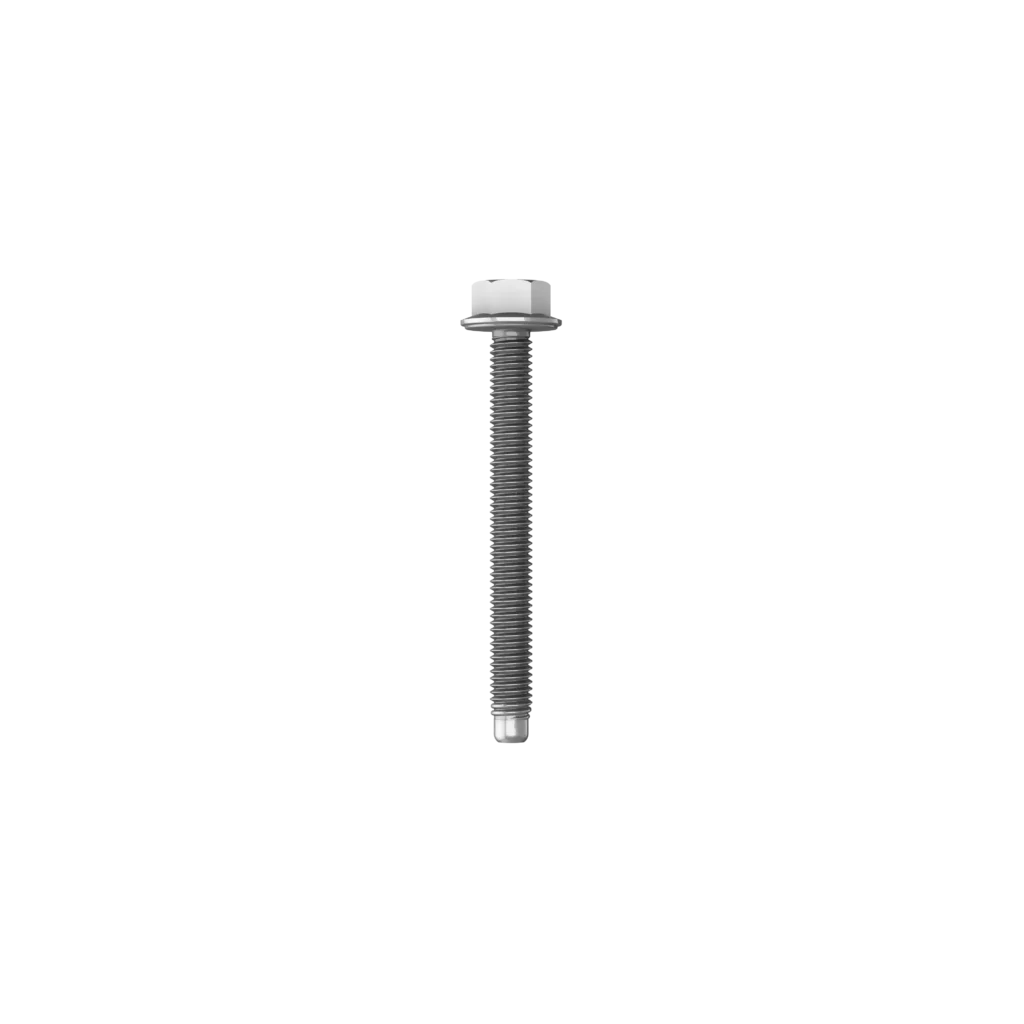

Self Forming Screws into Metal

Main properties

• Assembly into aluminum, zinc, steel and magnesium.

• Emphasis on compact application designs.

• Temperature expansion /contraction.

• Reusability and decreased debris generation.

Advanced coating solutions for enhanced multi-tightening performance

Competencies

• Special coating developed by Agrati Performance for multi-tightening

• Engineering development of special geometries

Main properties

• The coefficient of friction remains complaint within the specified range (6 points) throughout 5 tightening cycles

• Weight reduction compared to standard steel solution

Applications

• Wheels (Bolts / Nuts)

• Battery packs (cover)

• Body area

• Chassis area

• Interiors area

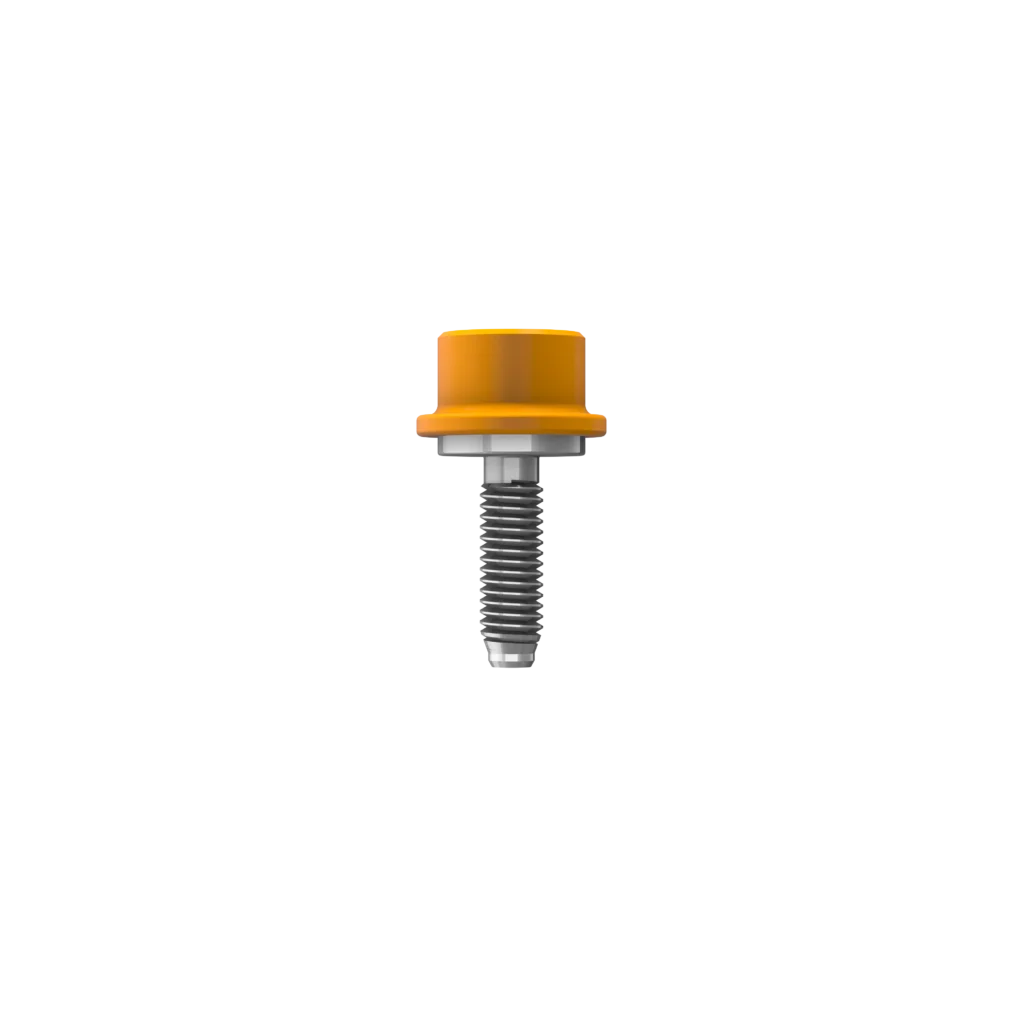

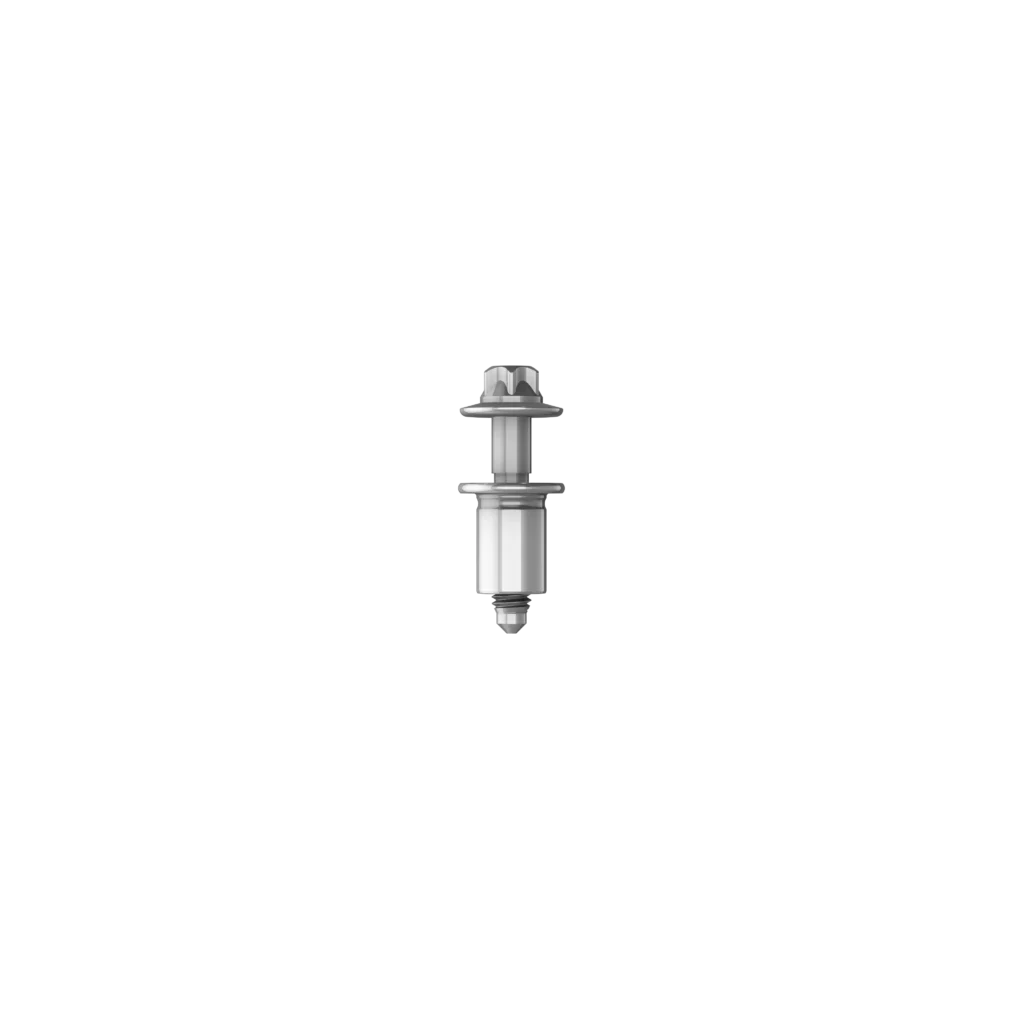

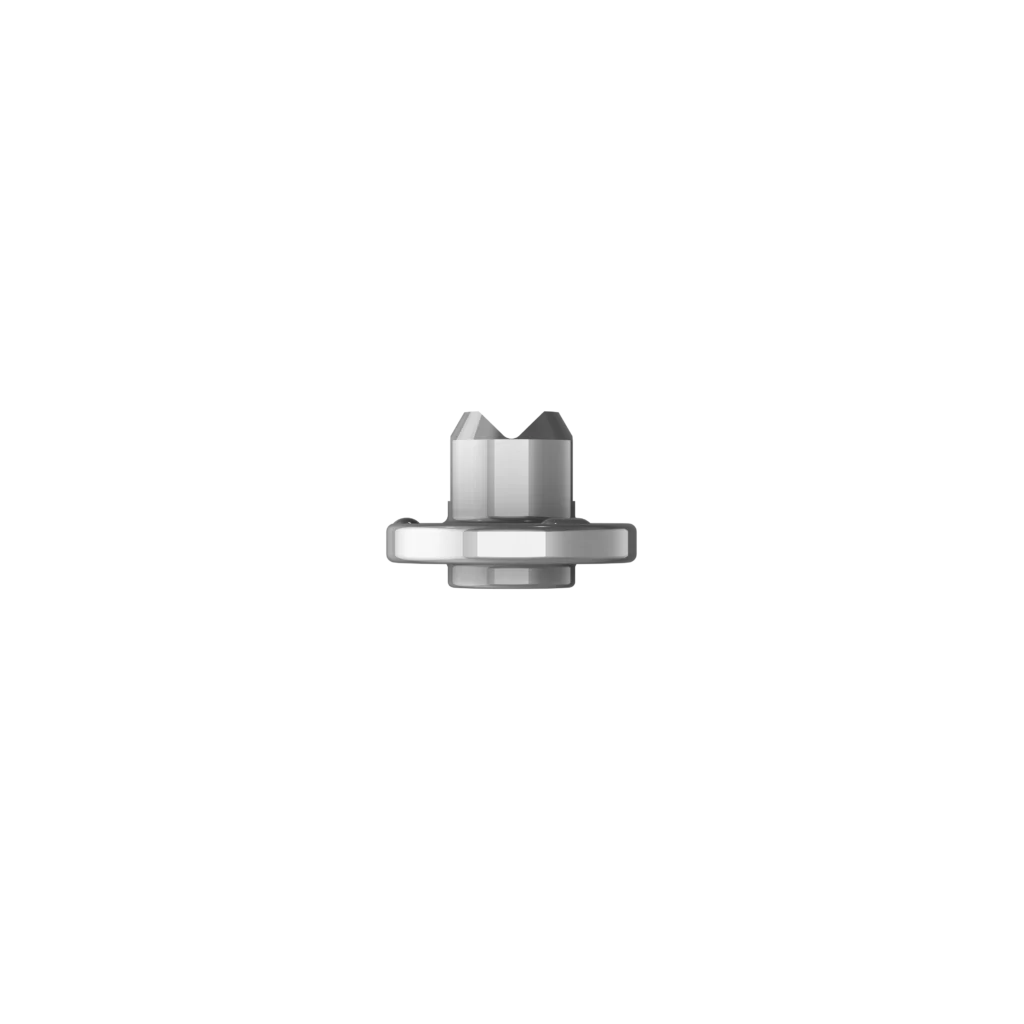

Anti-Cross Threading

Main properties

• Fixed Cross-Threading

• Improve assembly ease

• Eliminates hand starting

• Assist in alignment

• Clears paint filled threads

• Unaffected by installation speed

Self Forming Screws into Plastic

Main properties

• Suitable for a wide range of plastic, thermoplastics, thermosets and composite materials.

• Maximum resistance to back-out and pull-out.

• Minimizes boss failure.

• Resistance to vibration loosening.

• High strength and in-place reliability.

• Achieve higher clamp loads and seating torques.

• Use the same hole without loss in performance.

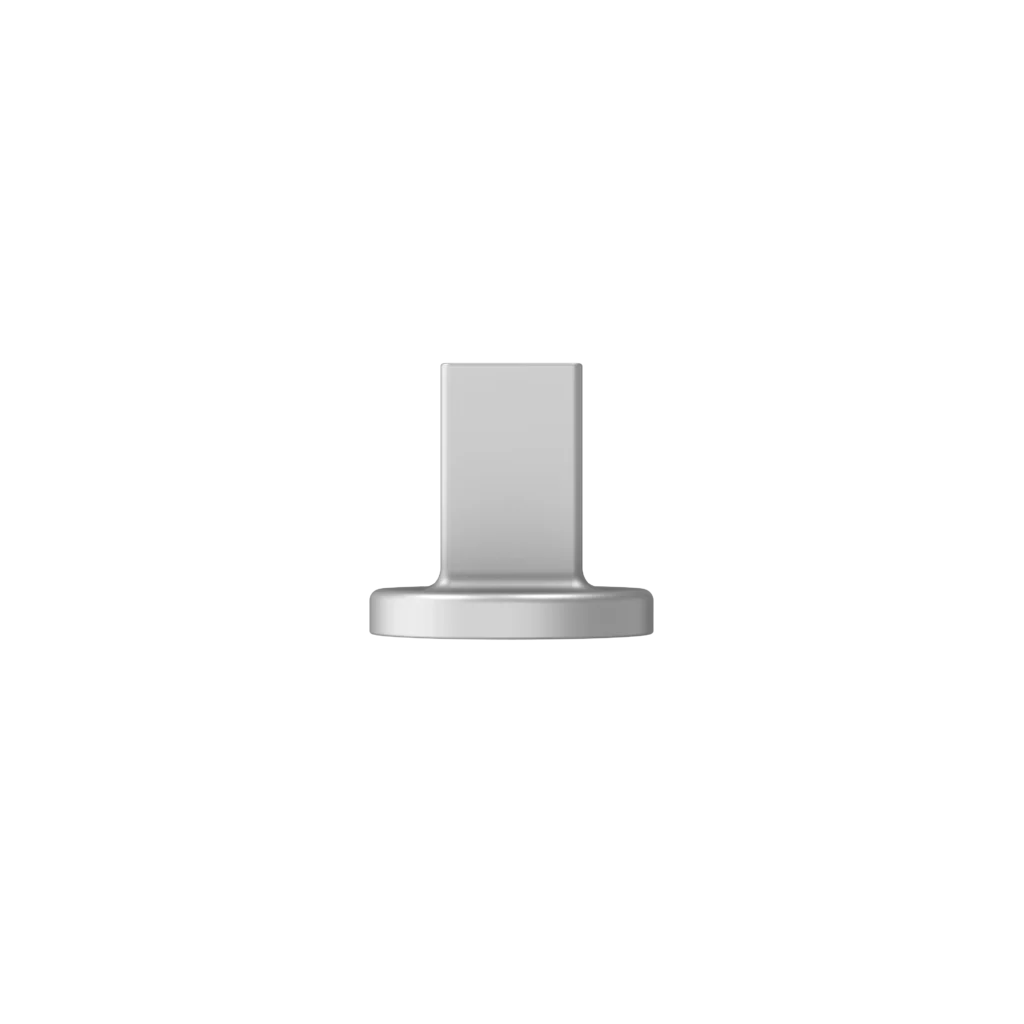

The ultimate customization and security solution

Competencies

• Agrati patent for the safety system

• In -ouse development engineering for new Monolock

• Responsible for validation test management for new Monolock development

Main properties

• Customizable key geometry

• Customizable cover geometry

• Responsible for validation test management for new Monolock development

• Possibility to paint the cover + apply markings/text

• Safety system integrated in the Monolock (quick release mechanism)

• Dedicated Tool to apply the correct torque

• Raw material: aluminum; steel; titanium

Applications

• Wheels (center lock)

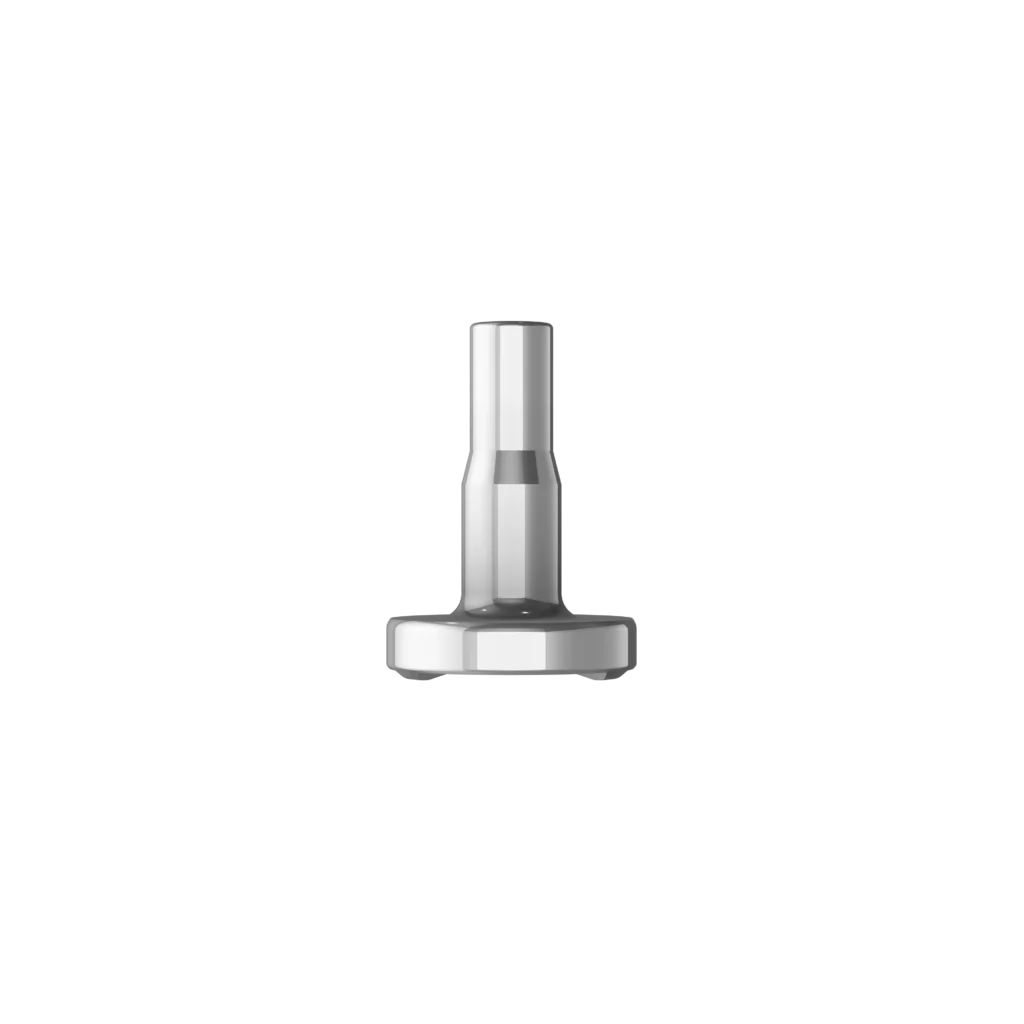

Threaded Insert

Competencies

• Metal insert for plastic reinforcement

• Anti-rotation performance

• Different geometries and features can be provided

Main properties

• Size: M5-M6

• Propety class

Applications

• Application in plastic components

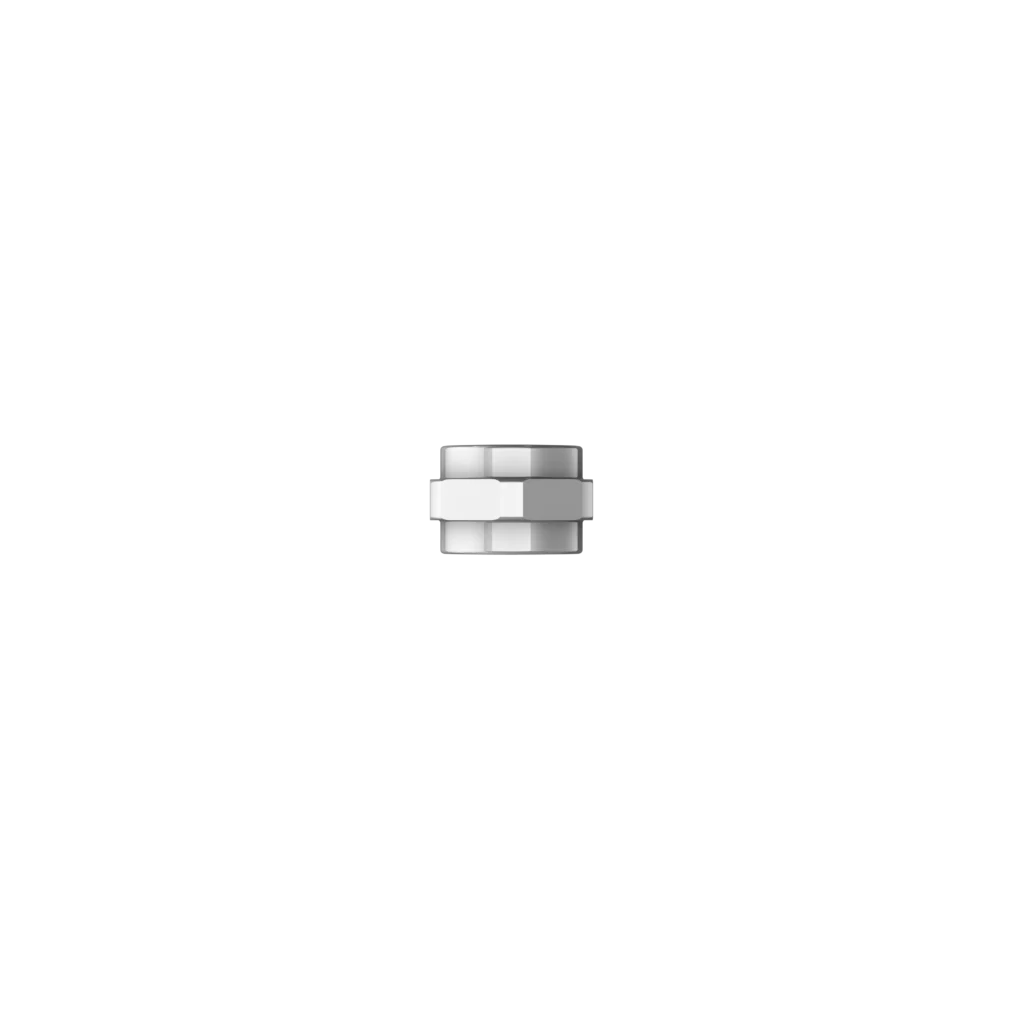

Spacer Nut

Competencies

• Multi functional fastener element

• Specific design to reinforce the battery pack structure in the joint positions

• Sealing performances to be guaranteed in combination with the counterbolts

Main properties

• Size: M16-M20

• Aluminum material

Applications

• Battery pack

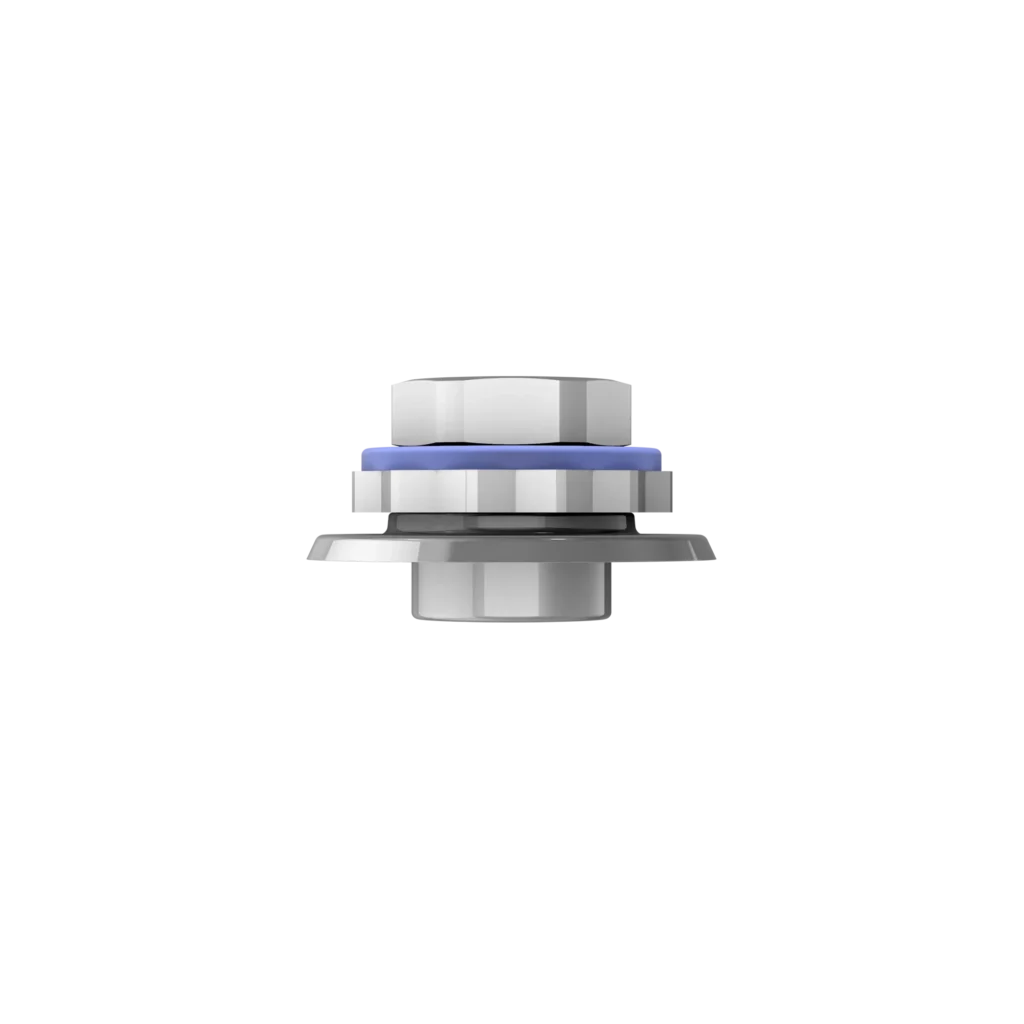

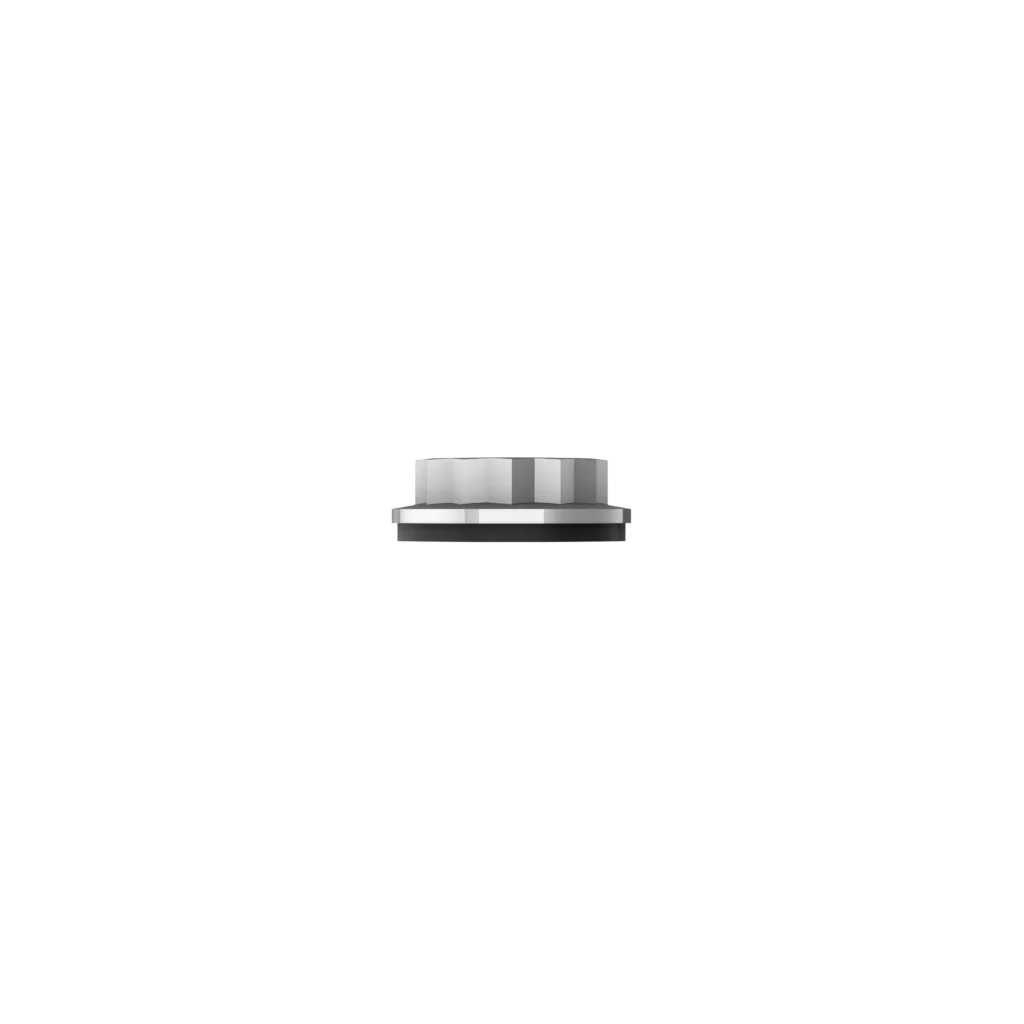

Nut with Sealing Functions

Competencies

• Different sealing solutions can be provided on fastener elements

• O-rings

• Special sealing patches

• Vulcanized rubbers

Main properties

• Property class: 8 – 10

• Size: M6 – M24

• Sealing function in the threaded area and/or on the bearing surface

Applications

• Battery pack

• Power electronics

Pipe Nut

Competencies

• Suitable materials for the welding process.

• Agrati optimized design is made by assembled metal sheet and special nut: nut with property class 8 or 10, metal sheet suitable for welding operations.

Main properties

•Size: M12-M16

• Property class 8-10

Applications

• Nuts for sheet metal components

Weld Nut

Competencies

• Standard nut design or special geometries can be provided

• Suitable materials for the welding process.

• Different surface finishes can be provided, depending on requirements

• Thread mask can be provided

Main properties

• Size: M5 – M16

• Proof load till class 12 with proper geometry

Applications

• Nuts for sheet metal components

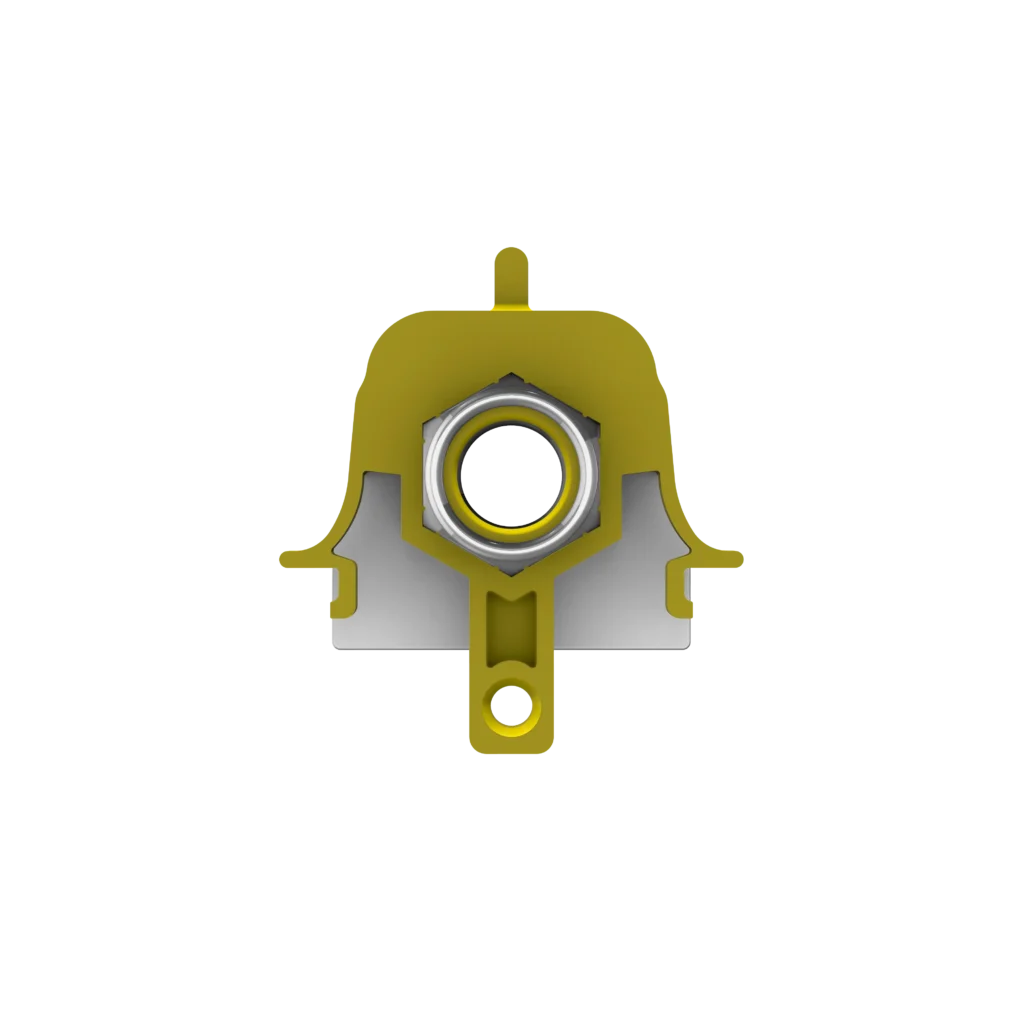

Cage Nut

Competencies

• Metal cage or hybrid solutions with metal – plastic materials are available

• Customized configurations can be designed

• Prevailing torque properties can be provided

Main properties

• Size: M12 – M14

• Property class 8-12

• Clearance recovery capabilities can be customized

• Reduction of non-quality costs related to tightening processes in assembly lines

Applications

• Nuts for sheet metal components

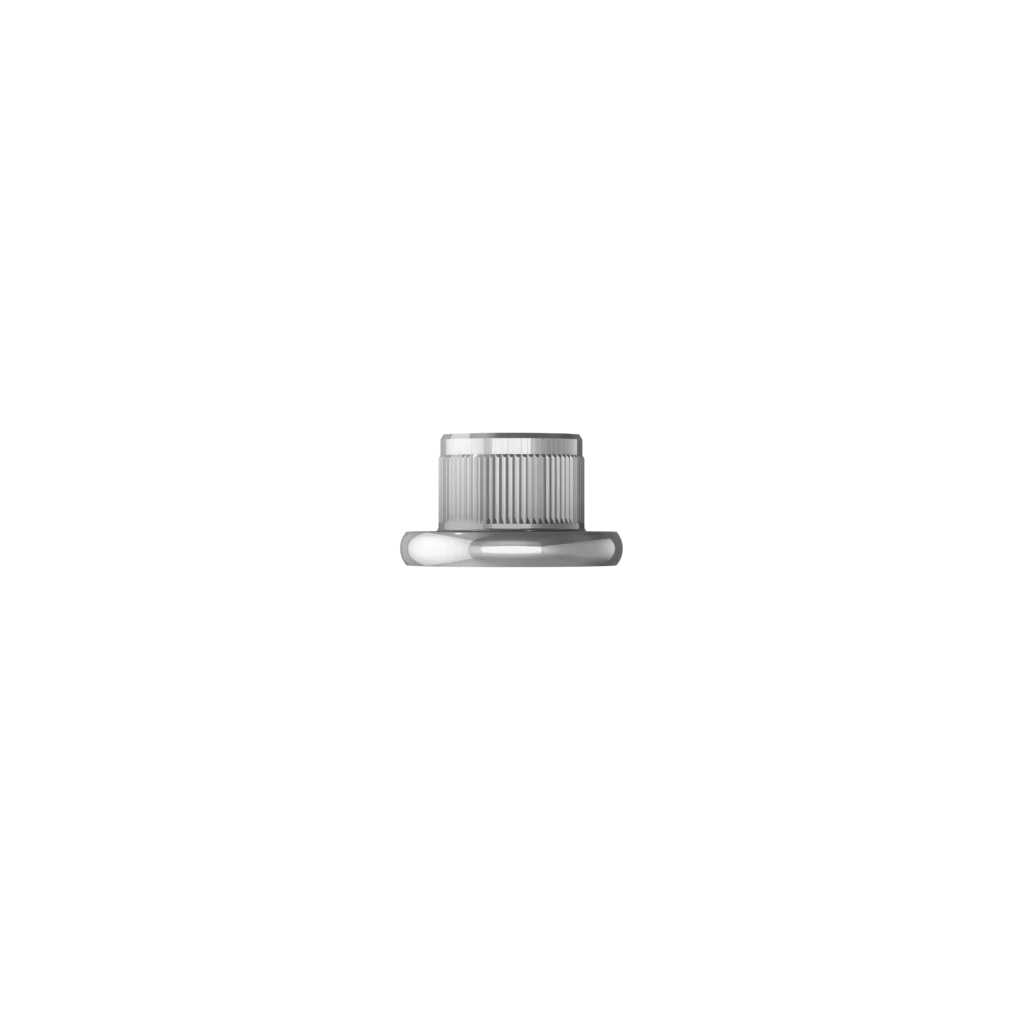

Threaded Insert

Competencies

• Knurling obtained by cold extrusion to ensure tighter tolerances, bringing to controlled interference levels with the aluminum counterpart

• Internal thread 100% mechanically controlled

• Controlled perpendicularity tolerance between the knurling feature / thread axis and the flange bearing surface

Main properties

•Size: M12 – M16

• Property class 8 – 10

• Insert to be pressed into the aluminum component

Applications

• Braking calipers

• Aluminum suspension components

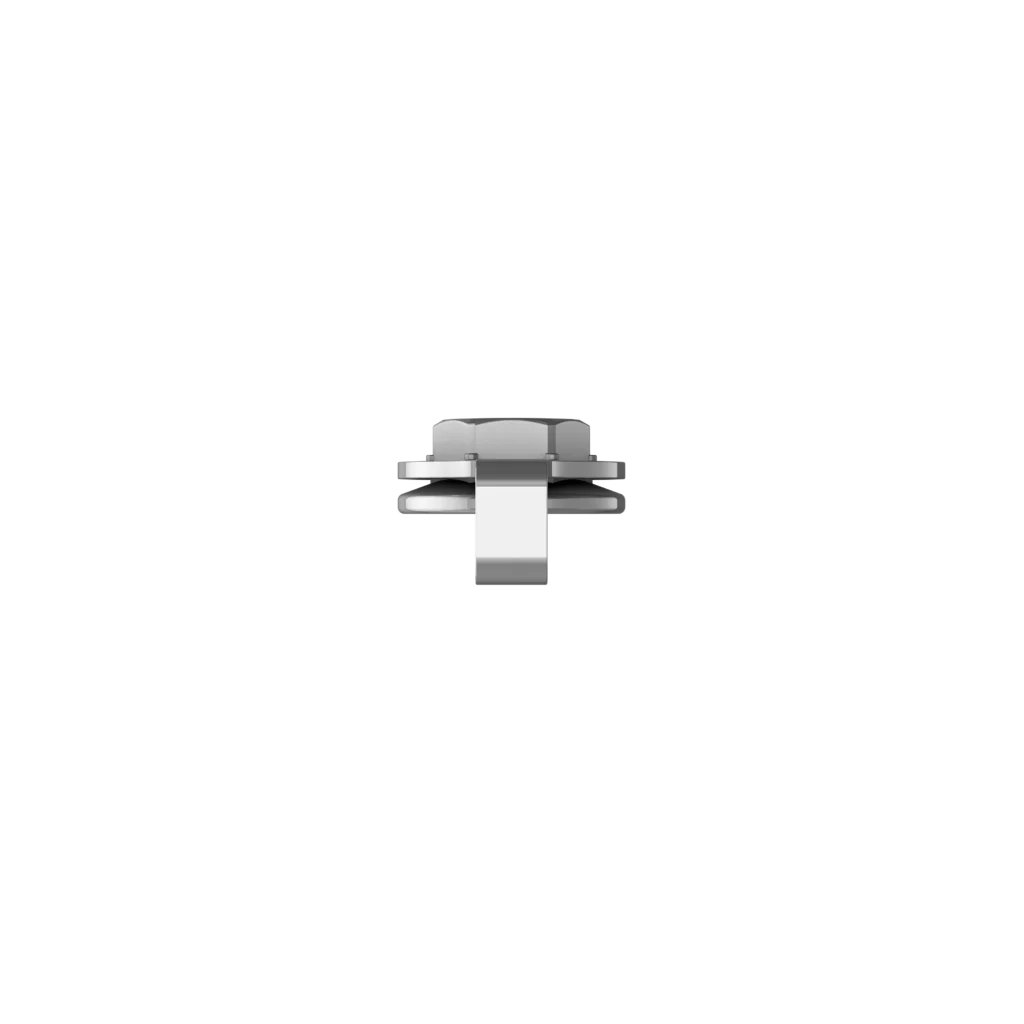

Flag Nut

Competencies

• The design of the sheet metal flag is customized in view of the specific counterpart

• Prevailing torque properties can be provided

Main properties

• Size: M6 – M20

• Anti-rotation effect of the nut

• Help the automatic assembly process

Applications

• Suspensions

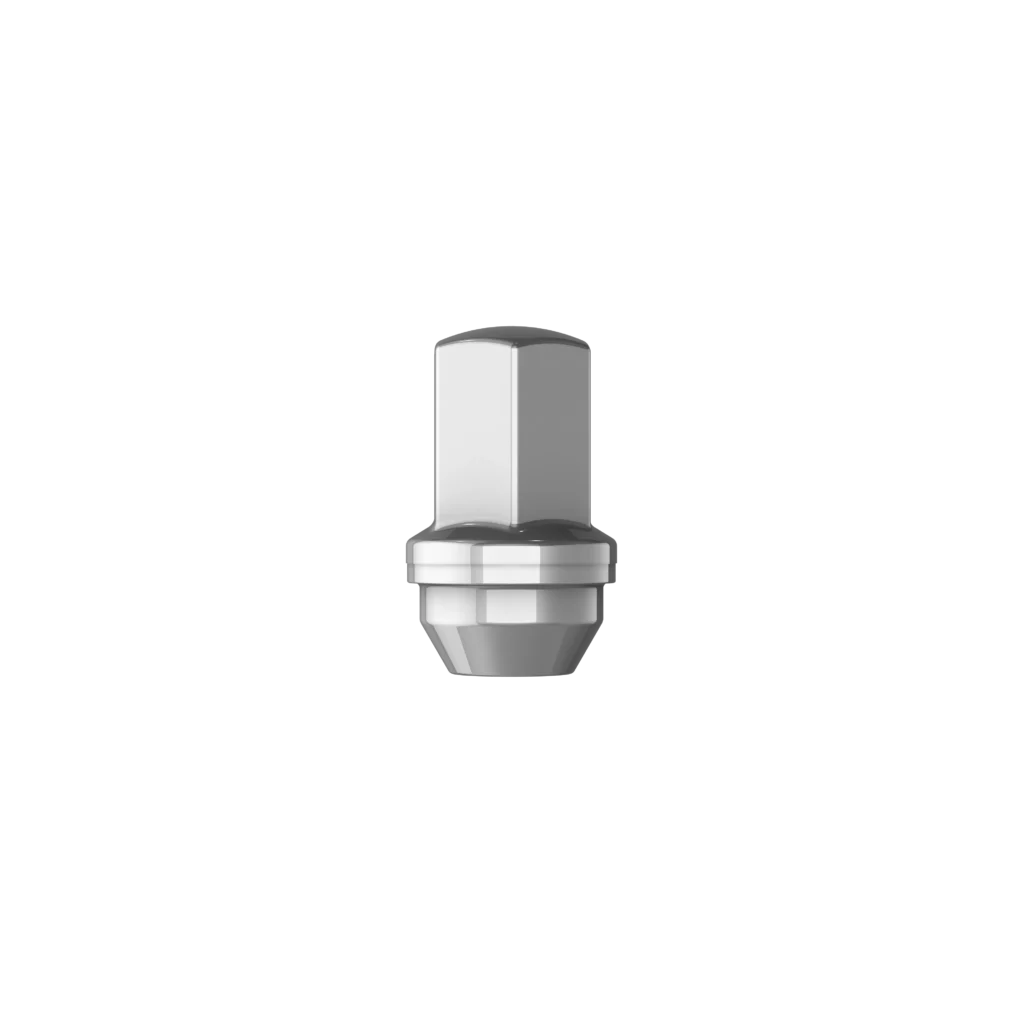

Wheel Nut

Competencies

• Different nut designs are available

• Stainless-steel caps can be assembled on the nuts, to ensure corrosion resistance and aesthetic functions

Main properties

• Size: M12-M14

• Property class: 8 – 9

• Watertightness of assembled stainless steel cap

Applications

• Fixations of wheel rims to hub

Chassis Nut

Competencies

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance and controlled friction coefficient

• Prevailing torque properties can be provided (nylon rings or metallic deformation)

• Products available with captive-washers too

• Lightweight design can be provided

Main properties

• Size: M5 – M20

• Property class 8 – 12

Applications

• Suspensions

• Steering system

Exhaust Line Nut

Competencies

• High nut to cover the full stud length, thus preventing the corrosion phenomenon on the stud

Main properties

• GA property class + silver/copper coating

• All-metal self-locking effect not affected by temperature variations

• Size: M6 – M8

Applications

• Exhaust line

Differential Nut System

Competencies

• Fastening system with special features

• Multi-parts assembly

Main properties

• Double nut M33-M39 used for fixation and clearances adjustment

Applications

• Fixation of the main drive-shaft to rear differential system

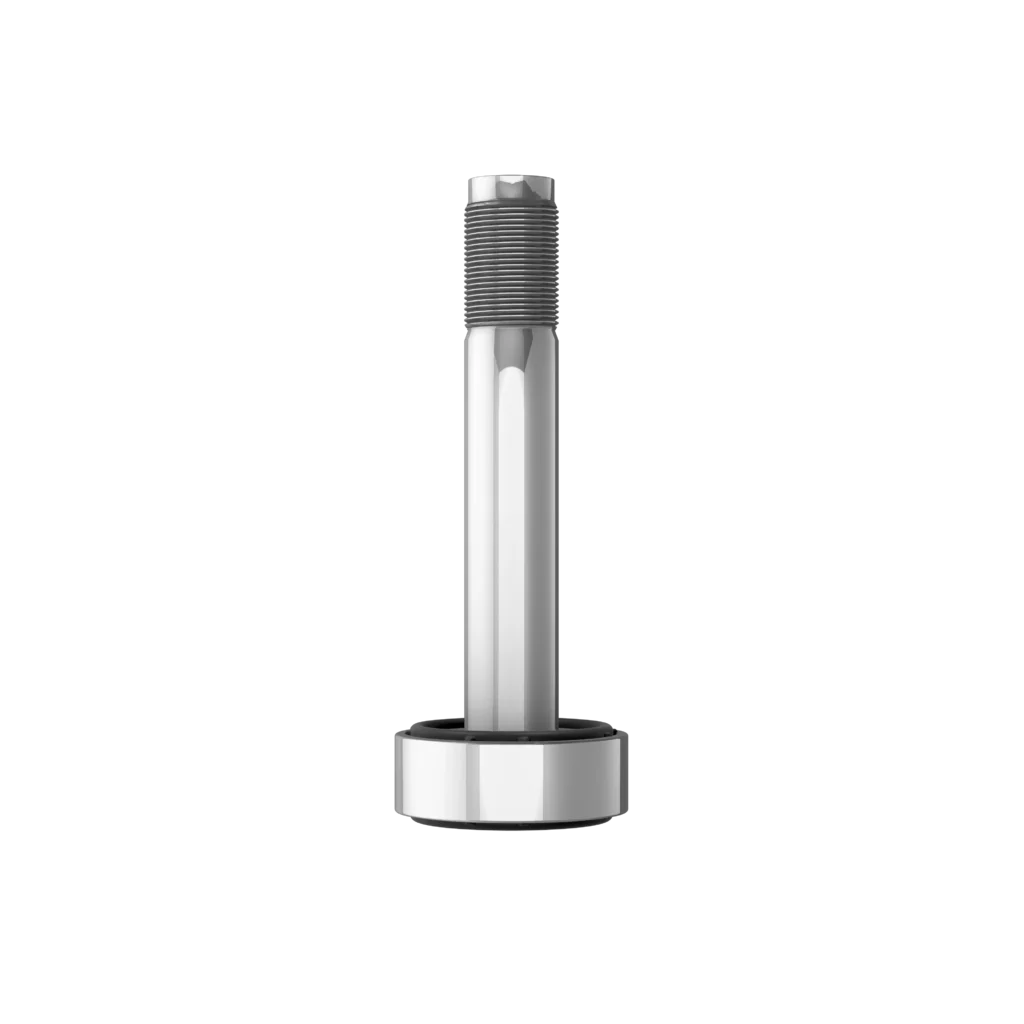

Drive-Shaft Nut

Competencies

• Standardized or special drive styles can be designed

• Hot forging + machining process guarantee high precision

• Different anti-loosening features can be provided

Main properties

• Size M20 – M33

• Single piece parts or nuts with captive washers

• Property class 8-10

Applications

• Transmission systems

• Half-shafts to hubs

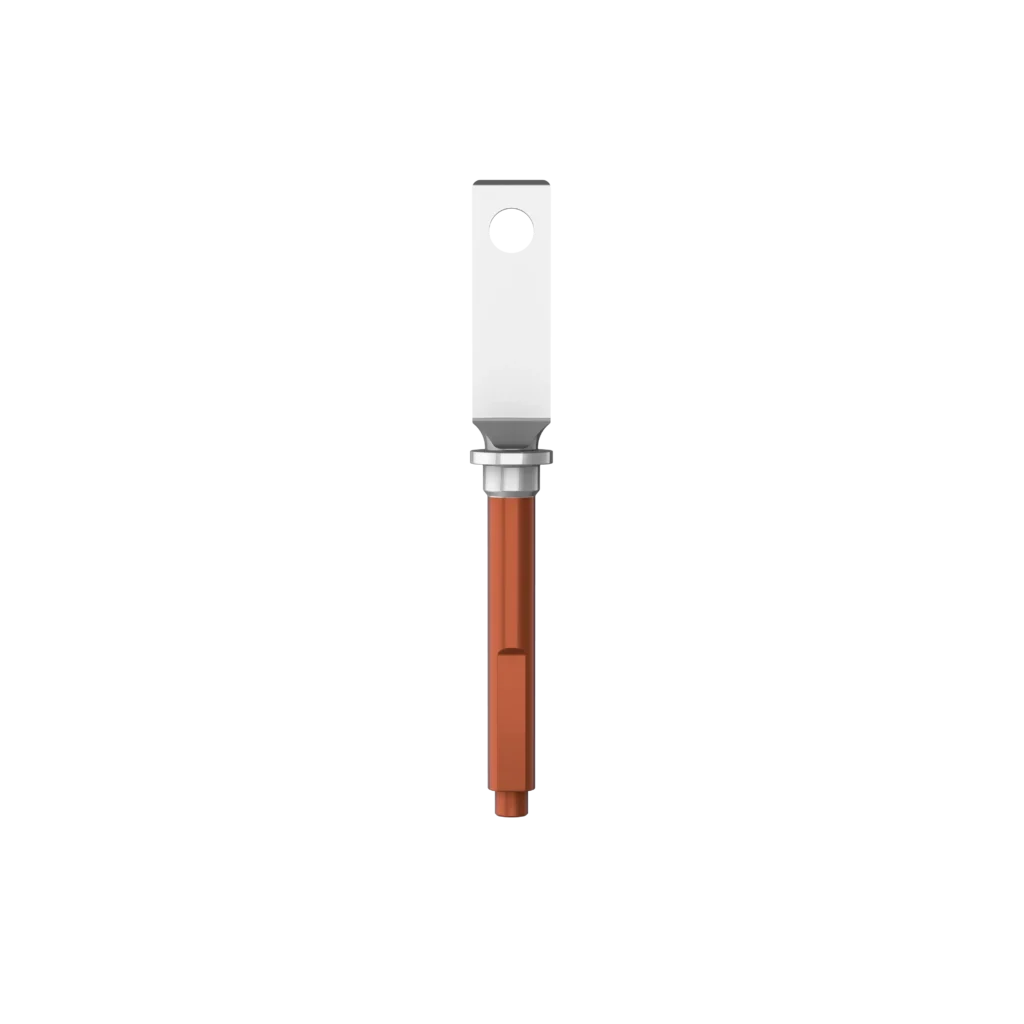

Touch-Safe Bolts

Competencies

• Fastener with electrical insulating properties

• Tailor made plastic materials can be formulated in view of specific requirements

• Part dimensions can be sized in view of customer needs

Main properties

• Thread size range: M3 to M6

• Property class: 8.8

• Touch-safe or Tool-safe functions can be designed

Applications

• Busbars fastening

• Power electronics

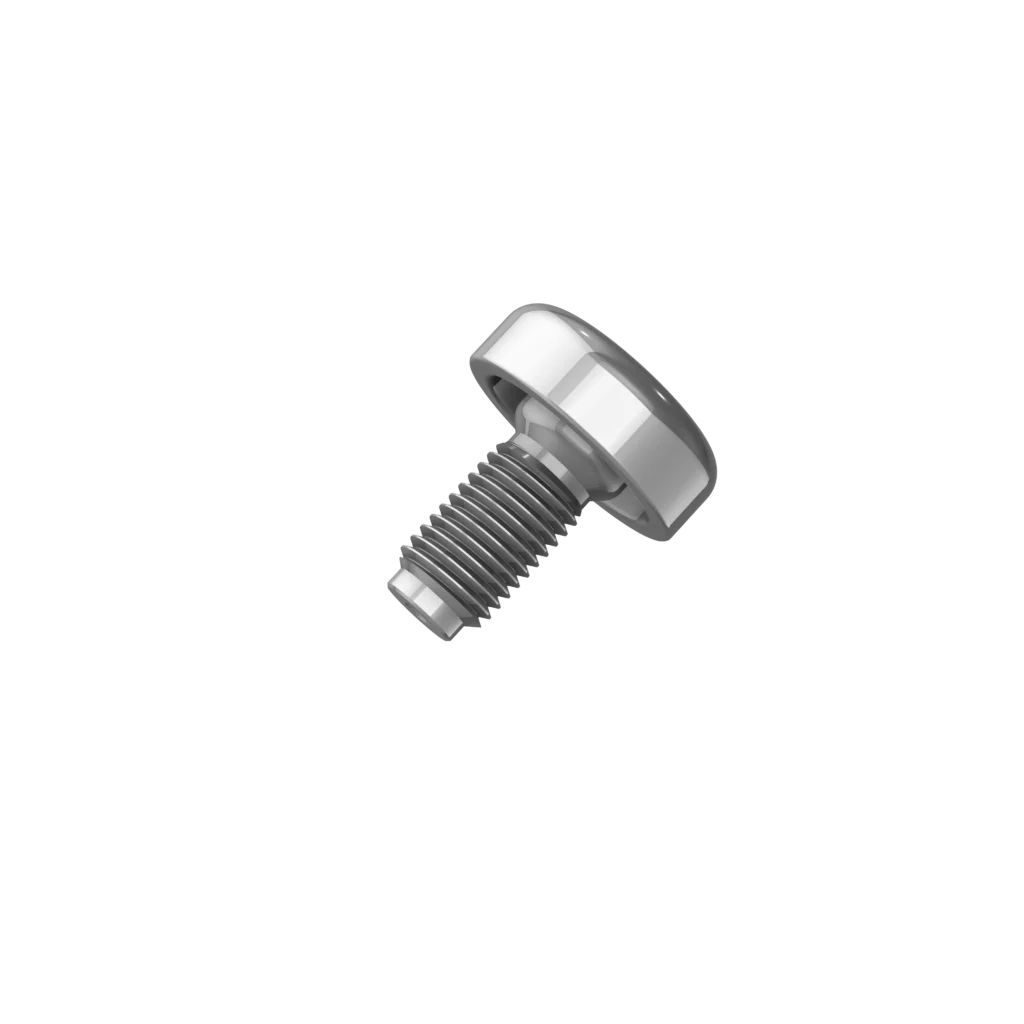

Bolt with Sealing Function

Competencies

• Different sealing solutions can be provided on fastener elements

• O-rings

• Special sealing patches

• Vulcanized rubbers

Main properties

• Sealing function in the threaded area

• Sealing function on the under-head surface

• Property class: 8.8 – 10.9

• Dimension: M6 – M16

Applications

• Battery pack

• Power electronics

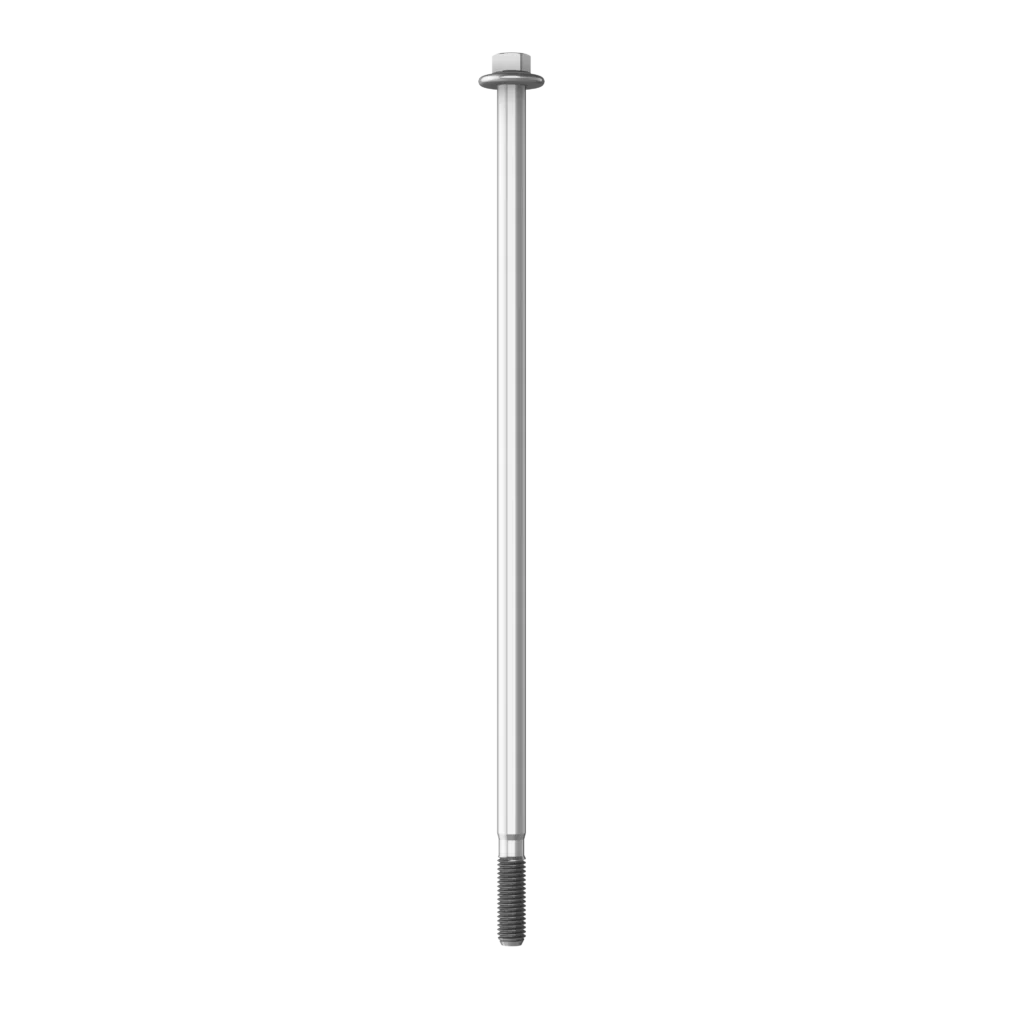

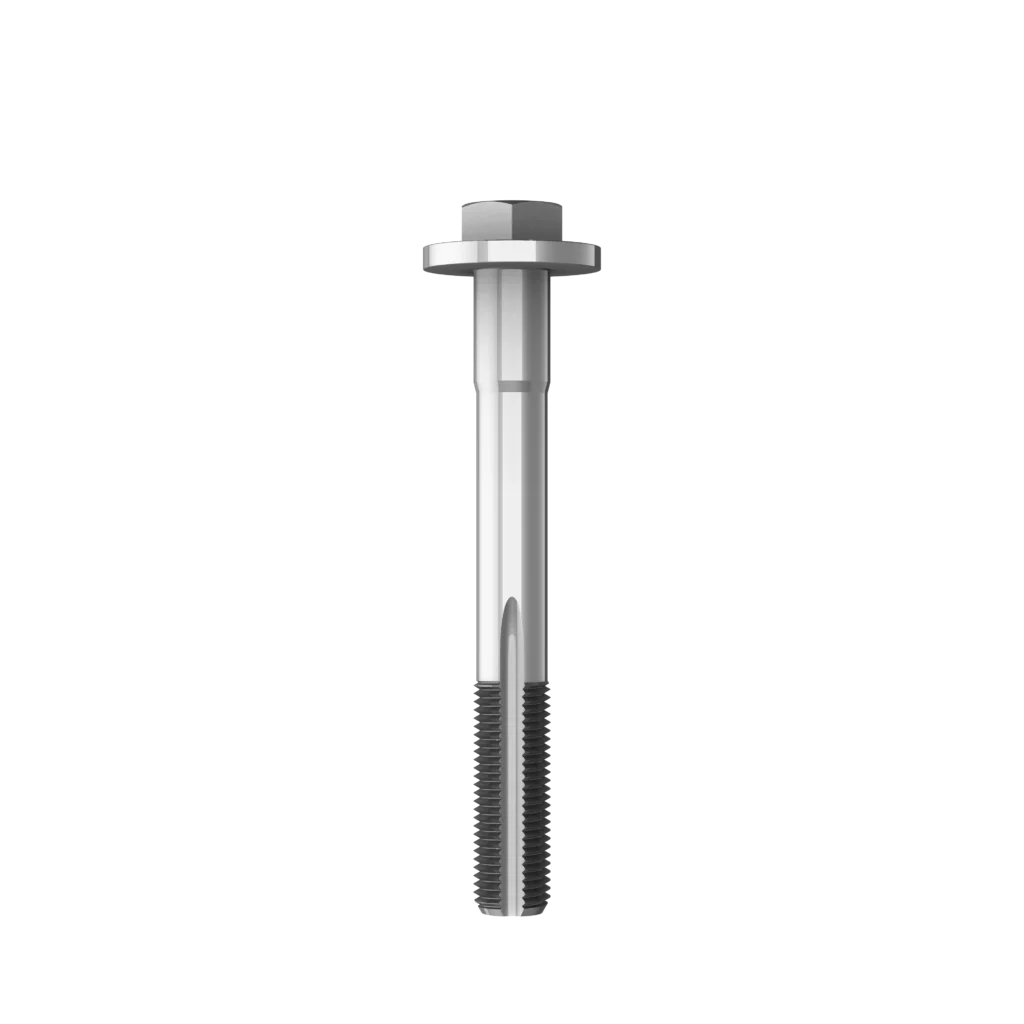

Long Bolt

Competencies

• Wide range of products in terms of lengths, geometry and processes

• Special cold forging machine to produce long bolts

Main properties

• Thread size range: M2 to M10

• Shank length range: special lengths up to 500 mm can be provided for thread sizes up to M6

• High cleanliness requirements can be managed

• Different thread diameters and thread positions

Applications

• Battery pack / modules

• Electric motor rotor/stator bolts

• Power tubes (e-bikes batteries)

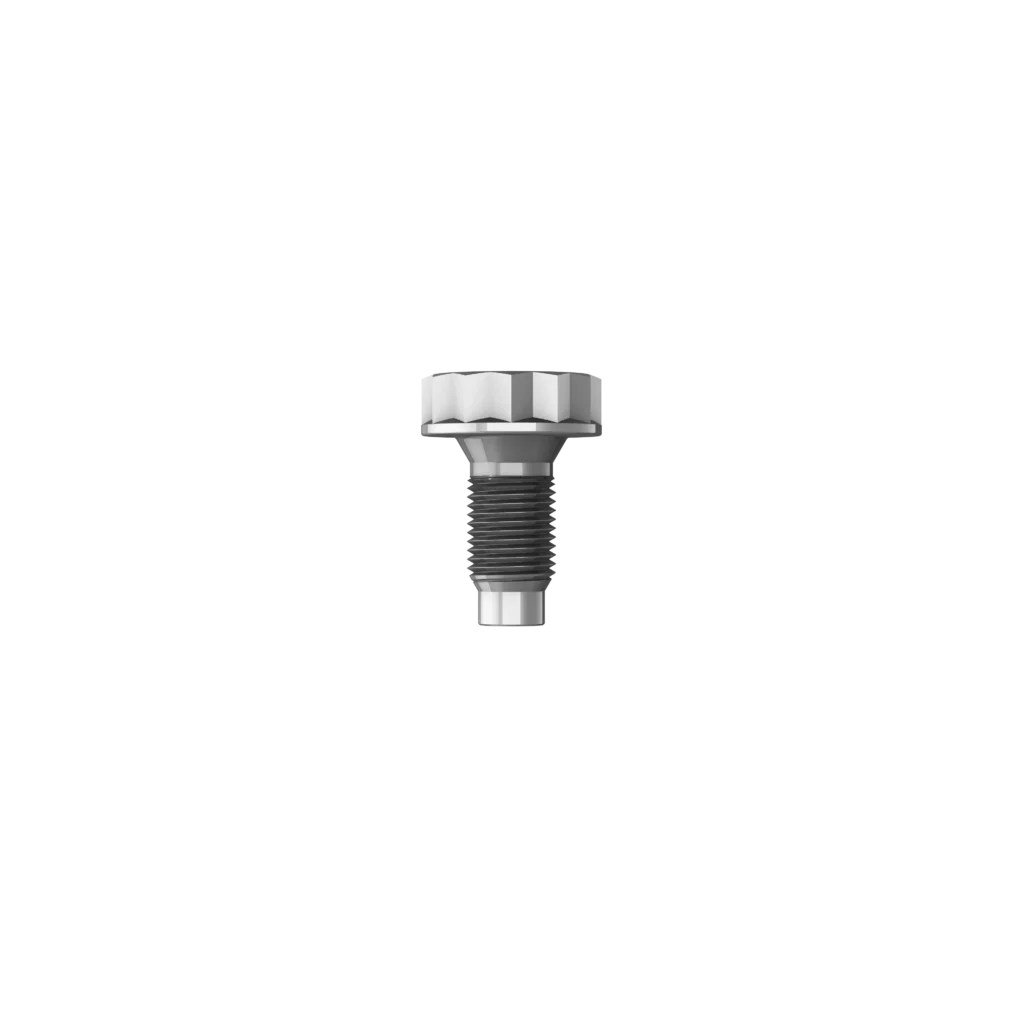

Bell Screw

Competencies

• Optimized forging process to obtain the special head shape

Dedicated controls to guarantee high quality levels

Main properties

•Size range M10

Property class: 8.8 – 10.9

Patch application can be managed to guarantee thread locking performances

Applications

• Standardized solution for seating frames fastenings

Shoulder Bolt

Competencies

• Calibrated shoulder realized directly by forging

• Different head styles are available

• Knurled version available

Main properties

• Size range M6 – M16

• Property class: 8.8 – 12.9

• Coatings: Zink Flake or Electrolytic

Applications

• Safety belt joints

• Seating systems

• All specific use where the screws has a not simple handling during the tightening activities

Weld Stud

Competencies

• Optimized geometry to simplify the production process

Main properties

• Size range M5 – M8

• Compatibility with existing welding equipments

Applications

• Fastening systems for BIW applications

• Grounding studs

Cambolt

Competencies

• Optimized design: assembled washer and milled groove

• Alternative versions (with forged grooves and integrated washer)

• Full systems with complementary products like counter-washer and nut can be supplied

Main properties

• Size range M10 to M20

• Washer Ø 32-45 mm

• Eccentricity 2.5-5 mm

• Property class : 8.8-12.9

• Coating : Zink Flake or others according to request

Applications

• Suspension systems

• Adjustment of camber /toe angle

• Multilink Systems

• Light truck

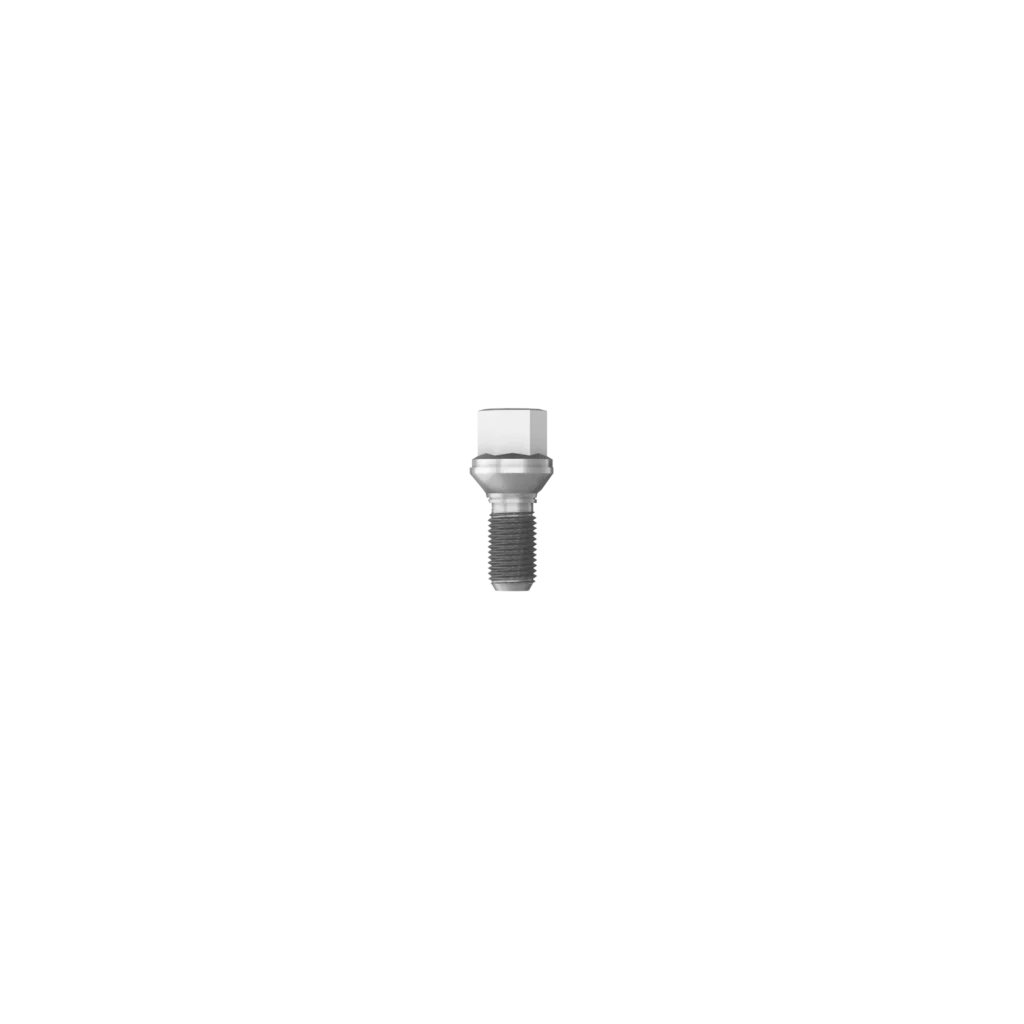

Wheel Bolt

Competencies

• Wheel bolt design can be realized with single piece design or with conical/spherical captive washer

• Special coatings or finishings can be provided

• Stability and reliability on multi-tightening can be guaranteed

• Aesthetic properties can be evaluated

Main properties

• Size range M12-M18

• Property class: 8.8-10.9 (special characteristics according to specific request can be managed)

• Special coatings, with strong rust resistance, developed internally by Agrati, in light or black finishing

Applications

• Fixations of wheel rims to hub

• Specific stud for big dimensions of wheels

Chassis Bolt

Competencies

• High strength bolts with customized requirements

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance

Main properties

• Size range M8 to M20

• Single-piece parts or bolt with captive washers

• Property class: 8.8 – 12.9

Applications

• Suspensions

• Steering system

• Brakes

Drive-Shaft Bolt

Competencies

• Standardized or special drive styles can be designed

• Anti-loosening features through locking patches

Main properties

• Size range M10 to M16

• Single piece parts or bolts with captive washers

• Property class 8.8-10.9

Applications

• Transmission systems

• Half-shafts to hubs

Bearing Bolt

Competencies

• Dedicated production process to guarantee reliability in critical applications

• Conversion of technology from machining to forging for costs optimization

Main properties

• Size range M12 to M24

• Tight tolerances to ensure long life to the bearing

• Hollowed parts to allow an inside lubricating system

• Cleanliness requirements can be guaranteed

Applications

• Gearbox shafts

• Gearbox case

Critical Engine Bolt

Competencies

• Dedicated production process to guarantee reliability in critical applications

• High and very high mechanical properties can be managed

Main properties

• Size range M8 to M20

• Cleanliness requirements can be guaranteed

• Property class : 8.8-12.9

• Property class over 12.9 can be managed according to customer request

• Rolling after Heat Treatment

Applications

• Cylinder head

• Conrod

• Main bearing

• Flywheel

• Pulley bolt

• Other engine applications

Welded Bushing

Competencies

• Complex geometries with projections realized by forging

• Geometry design suitable for welding process

• Great versatility for light weight approach

• Inner thread rolled or machined

Main properties

• Max diameter up to 50 mm

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to heat treat parts separately

• Weldability

• Surface finishing: blank or coating where needed

Applications

• Function as mother-thread

• Avoid heavy chassis structures

Chain Rollers

Competencies

• Need of medium-big forging machines

• Washing and rust protection required

Main properties

• Typical forging material

• Quench and tempered to high hardness values

• Tight tolerance on ID and OD

Applications

• Industrial chains of medium or big size vehicles or systems

Tank Fittings

Competencies

• Extreme forging cycle

• Part with shape suitable for welding on counterpart

• Threading of inner tapered thread

Main properties

• Very thin and large part

• High quality required due to assembly welding procedure

Applications

• Propane vessel

• Heating system

• Cooling system

Hose Fittings Blank

Competencies

• Forging on big size machine

• Complex forging cycle to achieve the required shape

• Rolling of marking

Main properties

• Blank to be fully machined on the ID to make hose coupling thread

• Marking to identify the product type by customer

Applications

• Hose fittings

Bolt Connectors

Competencies

• Forging special material not usually forged

• Design to avoid material waste

• Soft handling approach

Main properties

• Size range M5 to M10

• Material: Cooper Alloy (CuCrZr)

• Cleanliness

• Soft handling

• Coating : Ni, Ag (also partial coating)

• Electrical conductivity

Applications

• Power electronics

• E-Engines

Busbars

Competencies

• Complex geometries realized just by forging and stamping

• Design to avoid material waste

• Soft handling approach

Main properties

• Size range according to electric structures (Inverter, etc…)

• Material: Cooper (Cu-ETP)

• Cleanliness

• Soft handling

• Coating : Ni, Ag (also partial coating)

• Electrical conductivity

Applications

• Power electronics

• Control modules

• E-Engines

Battery Connectors

Competencies

• Complex geometries realized just by forging

• Design for sealing and fluid connection

• Lightweight and automation approach

Main properties

• Size range according to battery structures

• Material: Steel, Alu

• Cleanliness

• Soft handling

• Coating : ZnNi or similar e-coats

Applications

• Battery cooling system

• Assembly line automation

Battery Reinforcement

Competencies

• Complex geometries realized just by forging

• Geometry design suitable for sealing and battery assembly requirements

• Lightweight and automation approach

Main properties

• Size range according to battery structures

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or similar e-coats

Applications

• Structure reinforcement

• Battery Sealing

• Battery final assembly on car

• Assembly line automation

Shaft

Competencies

• Extrusion and fine blanking technology

• Secondary turning operation

• Small size forging machine with long kick out

• Centerless grinding

Main properties

• Slender part

• Corrosion resistance

• Small linearity and concentricity tolerances required

• complex shape

Applications

• Seats regulation

• Armrest regulation

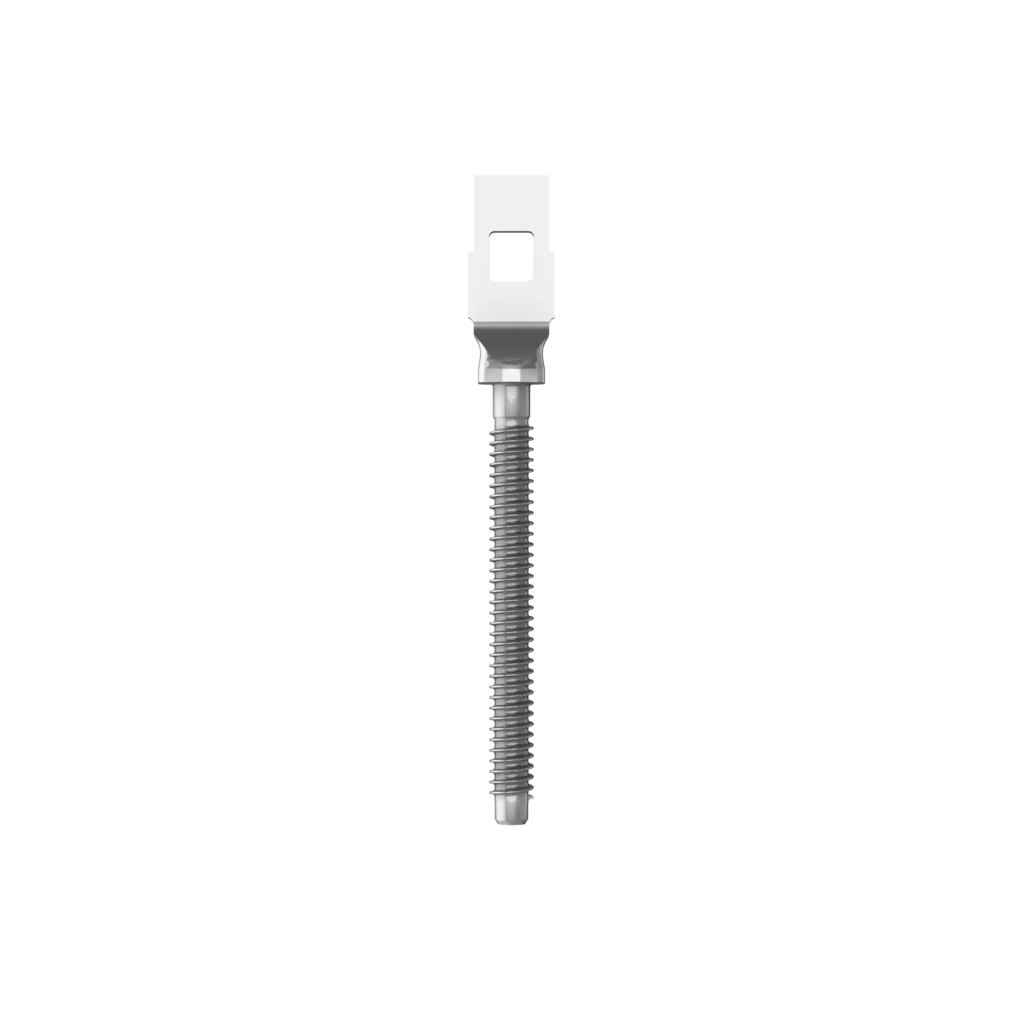

Lead Screws

Competencies

• Deformation of head on vertical press technology

• High cleanliness level required Zn coating

• Rolling of thread by dedicated machine with rollers

Main properties

• Low thread roughness

• Thread interfaced to the electric engine by plastic nut

• Handling and coating focused to reduce surface damages

• High fatigue performances

Applications

• Seats regulation

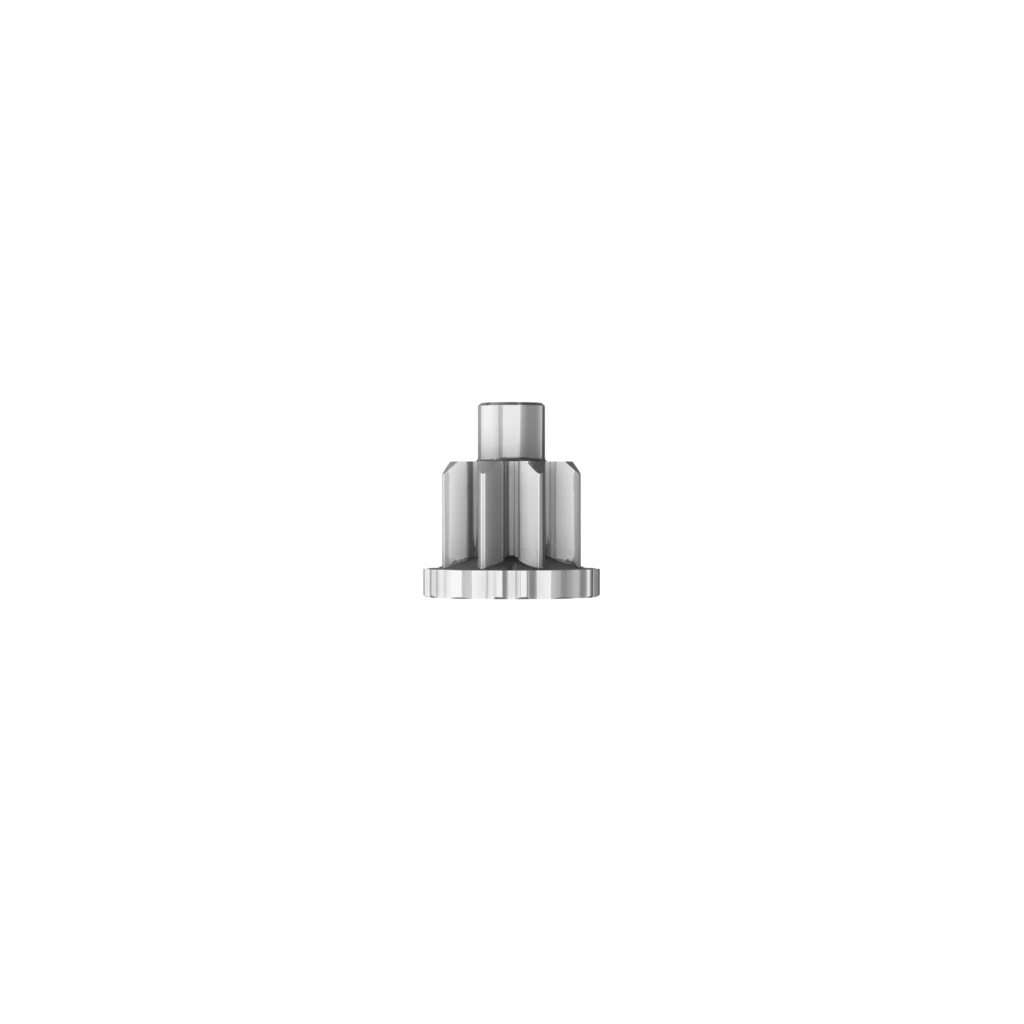

Pinion

Competencies

• Cold forged extruded shape

• High quality level and precision

• High mechanical properties

• High cleanliness and dedicated handling

• Dedicated machining

• Dedicated laser 100% sorting equipment

Main properties

• Gear quality class range 10-12

• Reference Pinion module 2.1and internal gear module 1.3

• Core hardness ∼ 350 HV10

• Surface hardness ∼ 700 HV10

• External cam profile fine blanked

• Internal gear profile extruded

• Absence of oxydation and shocks thanks to positioned H.T. in chamber furnace

• Overmoulded pinion

Applications

• Manual seat height adjuster

• Electric seat height adjuster

• Seats regulation

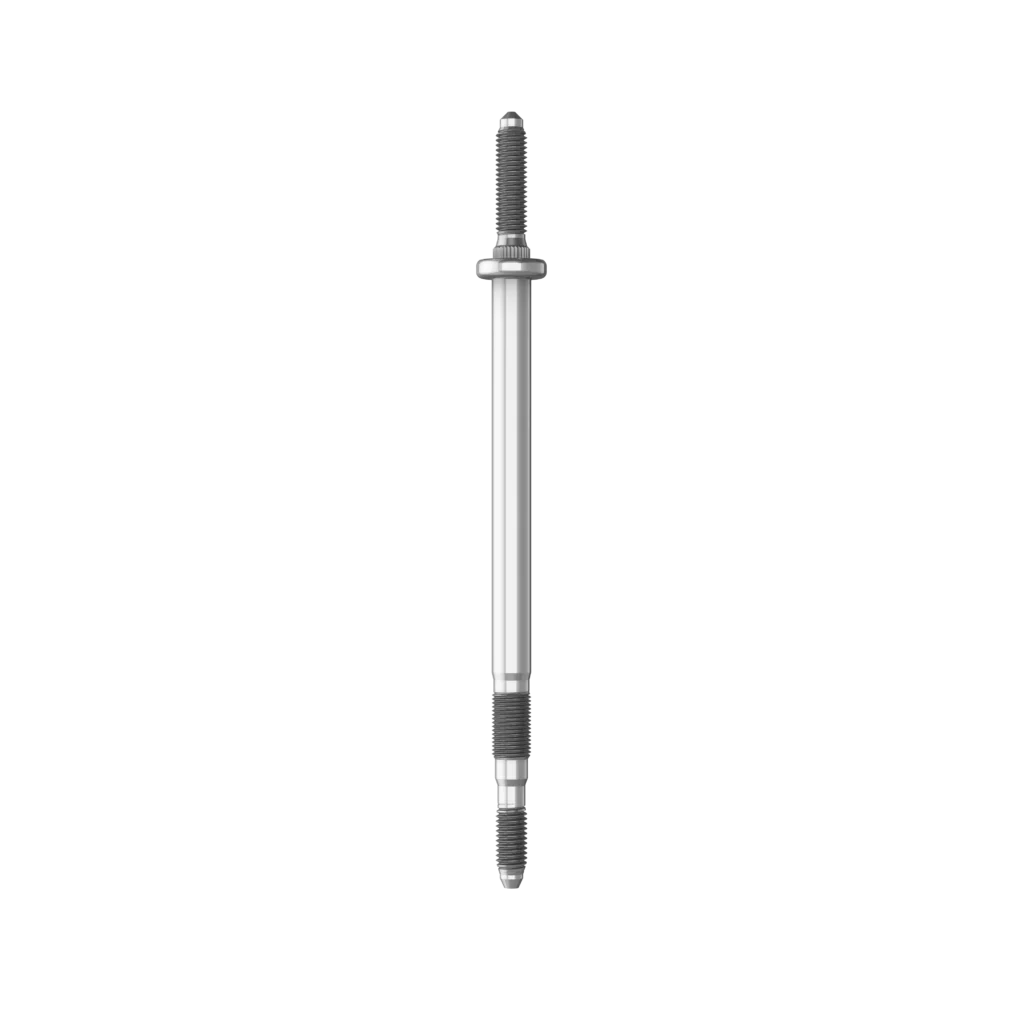

Tie-Rod

Competencies

• Dedicated forging cycle

• Syncronized rolling of different threads

• Calibration of long shank

• Heat treatment without bending effect

Main properties

• Low roughness on shank

• Tailored made knurling for press in metal sheet counterpart

• Low linearity tolerance

Applications

• Brake booster

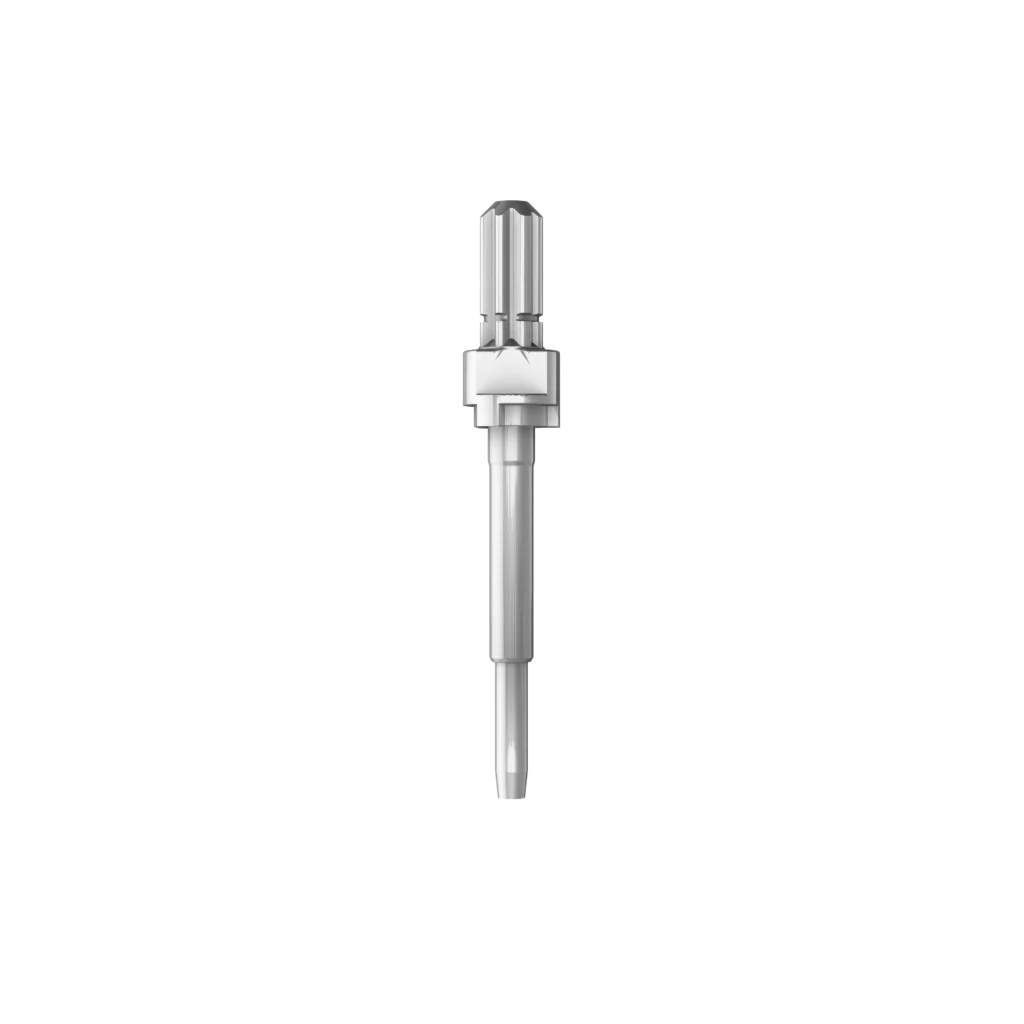

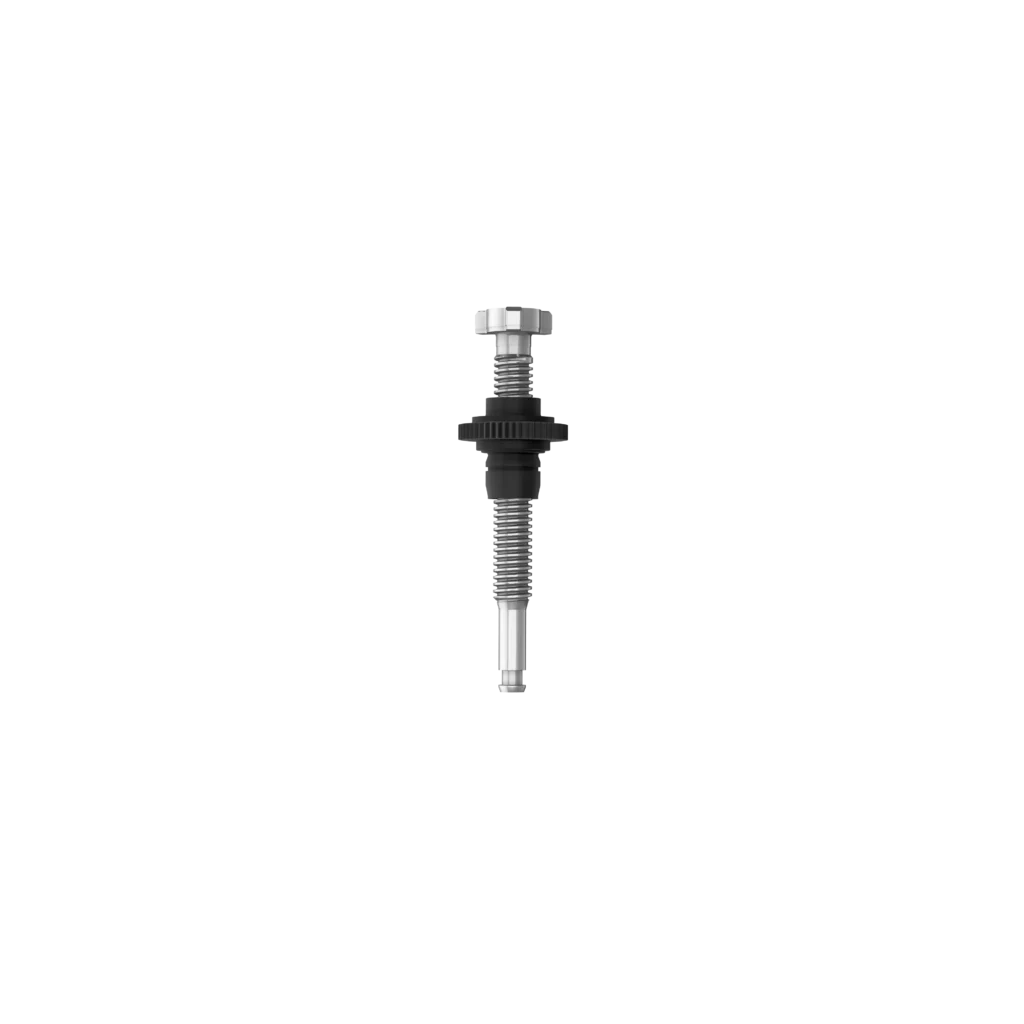

EPB

Competencies

• Dedicated multi-principal thread profile rolled by dedicated machine with rollers

• Extreme precision, quality and cleanliness of thread nut

• Shape developed by extreme forging and machining

• Dedicated assembly and sorting process

Main properties

• High fatigue performance required

• Handling and coating focused to reduce surface damages

• Dedicated working center for nut machining and thread rolling

• Optimized heat treatment for class 12 property class nut without oxidation

• Gear overmoulding

Applications

• Drum brake with integrated parking brake system

• Caliper with integrated parking brake system

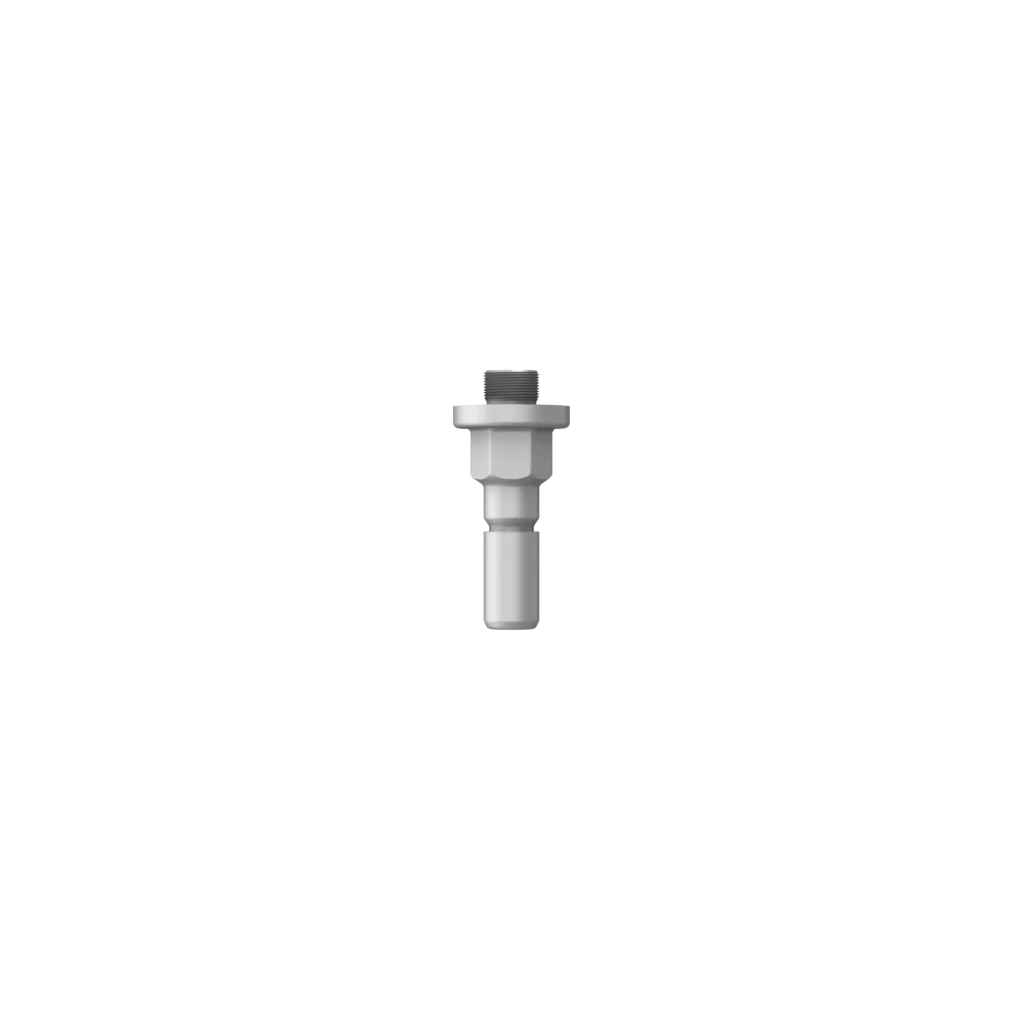

Guide Pin

Competencies

• Dedicated forging cycle

• Machining necessary to reach low concentricity and low surface roughness.

• Rolled knurl with specific design

Main properties

• Low roughness for pad sliding purpose

• Tailored made knurling for press in Alu caliper

• Low concentricity request

• Mech. Properties 12.9 for high bending load

Applications

• Fixed caliper brake system

Bushing

Competencies

• Complex geometries realized just by forging

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Weldability

Welding Solutions

Competencies

• Complex geometries realized just by forging and assembly

• Geometry design suitable for welding process

• Great versatility for light weight approach

Main properties

• Size range according to customer needs

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to Heat Treated parts separately

• Weldability

• Coating : Blank or coating where needed

Applications

• Function as motherthread

• Avoid heavy chassis structures

• Welding

Complex Geometries

Competencies

• Complex geometries realized just by forging

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Other material (rubber) integration for final application

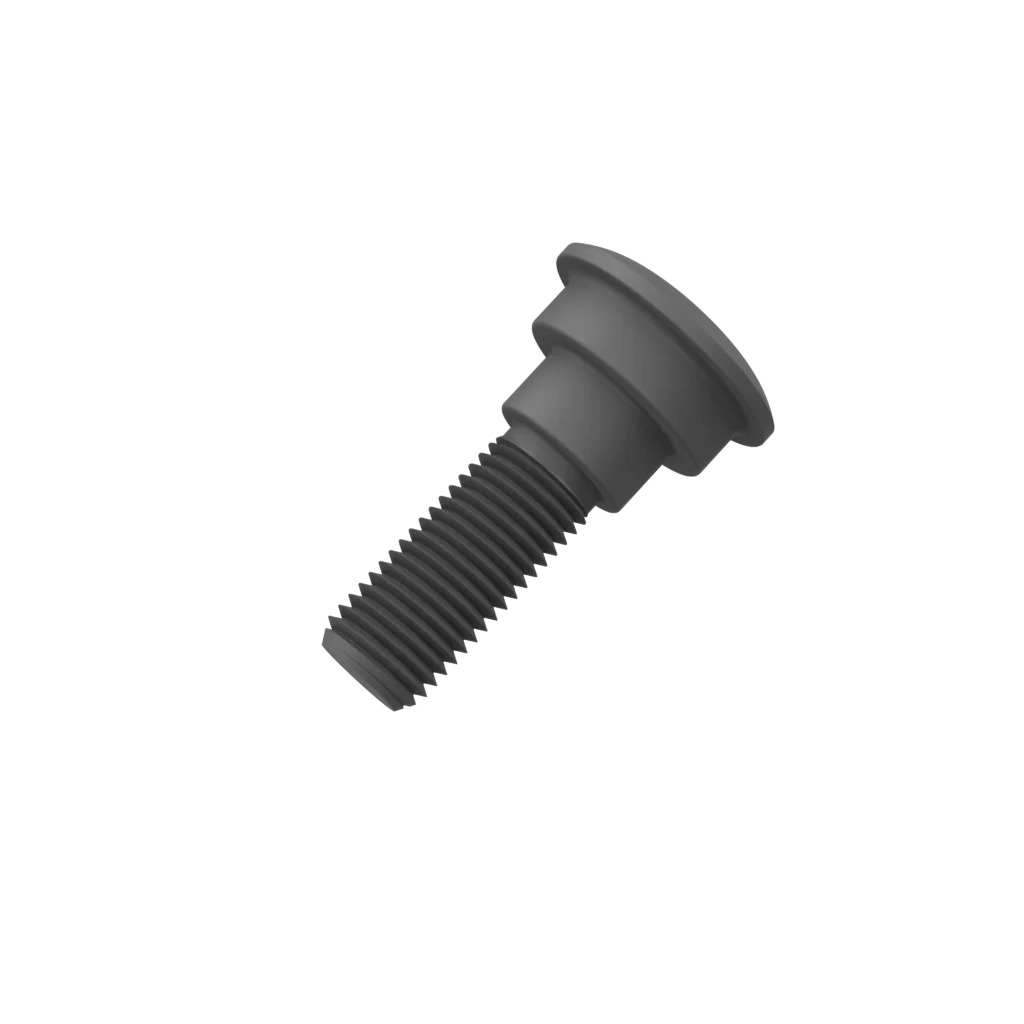

Collar Screw

Competencies

• Smart design for multi-performances in one component

• Geometry design suitable for assembly process

• Economic competitiveness

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

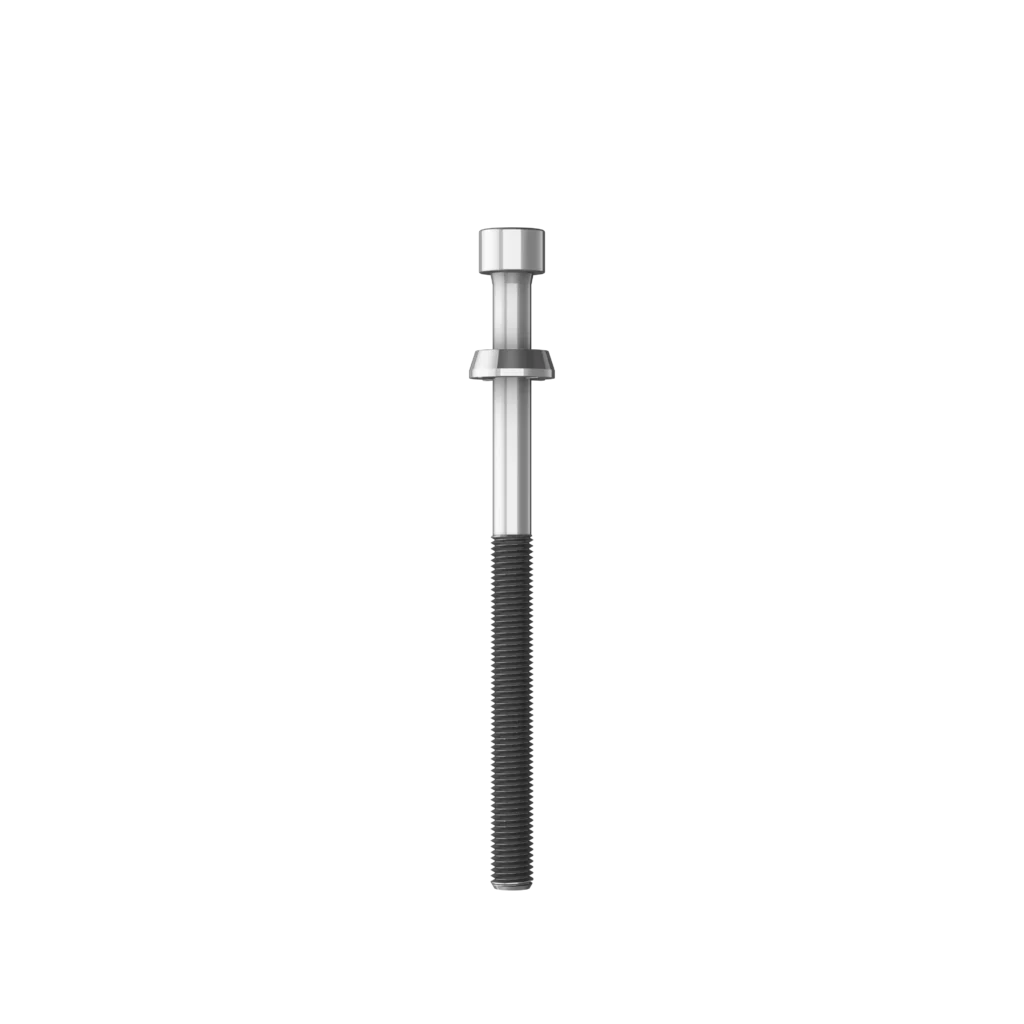

Captive Solution

Competencies

• Smart design for multi-performances

• Geometry design suitable for assembly process

• Final Assembly efficiency improvement

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

• Various solutions for screw/sleeve assembly

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

• Automatic assembly lines

Sleeve

Competencies

• Great control on tolerances

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness

Main properties

• Size range from Ø 5 to 40 mm

• Height tolerance up to 0.05 mm (ore less with grinding)

• Diameter tolerances up to 0.05 mm

• Material: Low Carbon Steel, Alu, Copper, Brass

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

Engineered components used in several automotive applications

Self Forming Screws into Metal

Main properties

• Assembly into aluminum, zinc, steel and magnesium.

• Emphasis on compact application designs.

• Temperature expansion /contraction.

• Reusability and decreased debris generation.

Advanced coating solutions for enhanced multi-tightening performance

Competencies

• Special coating developed by Agrati Performance for multi-tightening

• Engineering development of special geometries

Main properties

• The coefficient of friction remains complaint within the specified range (6 points) throughout 5 tightening cycles

• Weight reduction compared to standard steel solution

Applications

• Wheels (Bolts / Nuts)

• Battery packs (cover)

• Body area

• Chassis area

• Interiors area

Anti-Cross Threading

Main properties

• Fixed Cross-Threading

• Improve assembly ease

• Eliminates hand starting

• Assist in alignment

• Clears paint filled threads

• Unaffected by installation speed

Self Forming Screws into Plastic

Main properties

• Suitable for a wide range of plastic, thermoplastics, thermosets and composite materials.

• Maximum resistance to back-out and pull-out.

• Minimizes boss failure.

• Resistance to vibration loosening.

• High strength and in-place reliability.

• Achieve higher clamp loads and seating torques.

• Use the same hole without loss in performance.

The ultimate customization and security solution

Competencies

• Agrati patent for the safety system

• In -ouse development engineering for new Monolock

• Responsible for validation test management for new Monolock development

Main properties

• Customizable key geometry

• Customizable cover geometry

• Responsible for validation test management for new Monolock development

• Possibility to paint the cover + apply markings/text

• Safety system integrated in the Monolock (quick release mechanism)

• Dedicated Tool to apply the correct torque

• Raw material: aluminum; steel; titanium

Applications

• Wheels (center lock)

Threaded Insert

Competencies

• Metal insert for plastic reinforcement

• Anti-rotation performance

• Different geometries and features can be provided

Main properties

• Size: M5-M6

• Propety class

Applications

• Application in plastic components

Spacer Nut

Competencies

• Multi functional fastener element

• Specific design to reinforce the battery pack structure in the joint positions

• Sealing performances to be guaranteed in combination with the counterbolts

Main properties

• Size: M16-M20

• Aluminum material

Applications

• Battery pack

Nut with Sealing Functions

Competencies

• Different sealing solutions can be provided on fastener elements

• O-rings

• Special sealing patches

• Vulcanized rubbers

Main properties

• Property class: 8 – 10

• Size: M6 – M24

• Sealing function in the threaded area and/or on the bearing surface

Applications

• Battery pack

• Power electronics

Pipe Nut

Competencies

• Suitable materials for the welding process.

• Agrati optimized design is made by assembled metal sheet and special nut: nut with property class 8 or 10, metal sheet suitable for welding operations.

Main properties

•Size: M12-M16

• Property class 8-10

Applications

• Nuts for sheet metal components

Weld Nut

Competencies

• Standard nut design or special geometries can be provided

• Suitable materials for the welding process.

• Different surface finishes can be provided, depending on requirements

• Thread mask can be provided

Main properties

• Size: M5 – M16

• Proof load till class 12 with proper geometry

Applications

• Nuts for sheet metal components

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.