Agrati produces over 5 million screws every day, primarily dedicated to the automotive market. In order to ensure high standards of quality, nearly all processes, such as tooling, wire drawing, cold forging, thread rolling, and heat treatments, are carried out internally or, in some specific cases, through qualified suppliers. This allows us to offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements.

IN THIS SECTION

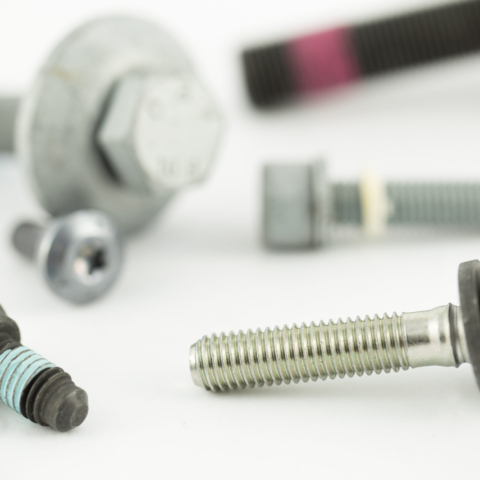

SCREWS OF HIGH QUALITY

When it comes to screw production, Agrati, leveraging its experience, is capable of handling customized mechanical characteristics, allowing for the production of high-strength screws in classes 12.9, 14.9, 12.8, or 14.8.

Our team of engineers design and develop screws based on the customer’s request, working in constant collaboration to study the best solution that aligns with the specific needs of the automotive market.

Screws find various applications, including suspension, brakes, steering, wheels, body and interior, safety systems, engine, and transmission.

A SIMPLE BUT ESSENTIAL PRODUCT

Technically, a screw is a mechanical element comprising an externally helix-threaded shank and a head that facilitates tightening with a specific tool.

Despite being a simple product, screws play a crucial role in car assembly, ensuring the safety of both the vehicle and its passengers.

EXPERIENCE AND INNOVATION

High-strength screws are produced using cold forging machines, and the thread is obtained through rolling operations, avoiding material removal. This approach reduces time, production costs, and enhances product accuracy.

In addition to standard screws, we can also offer products with captive washers, self-aligning ends to streamline automatic assembly, and anti-unscrewing elements like thread-locking pads that guarantee secure fastening.

Our team of engineering and innovation experts studies the screw’s geometry and mechanical properties, optimizing them to minimize weight and fulfill the automotive market’s demand for lightweight and downsized products.

These technologies, in combination with precise heat treatments, allow us to achieve and ensure the mechanical properties in compliance with ISO 898-1 or customer-specific regulations.