We offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements

Agrati produces over 5 million screws every day, primarily dedicated to the automotive market. In order to ensure high standards of quality, nearly all processes, such as tooling, wire drawing, cold forging, thread rolling, and heat treatments, are carried out internally or, in some specific cases, through qualified suppliers. This allows us to offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements.

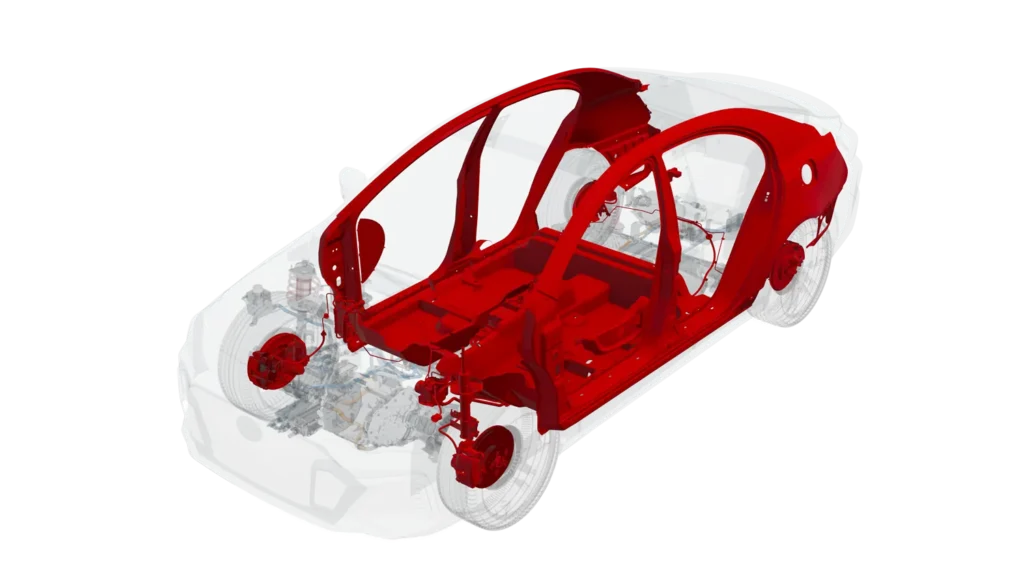

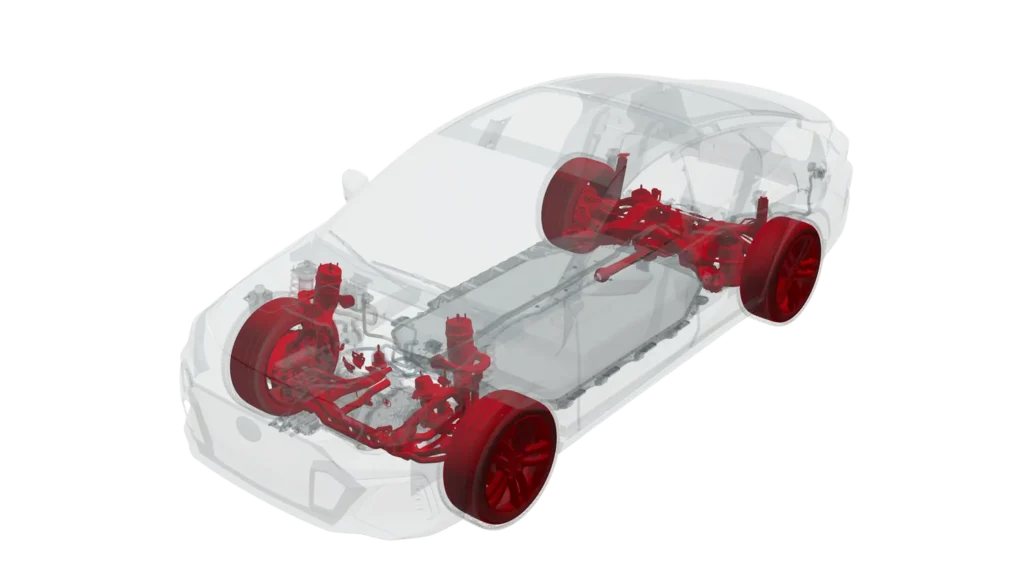

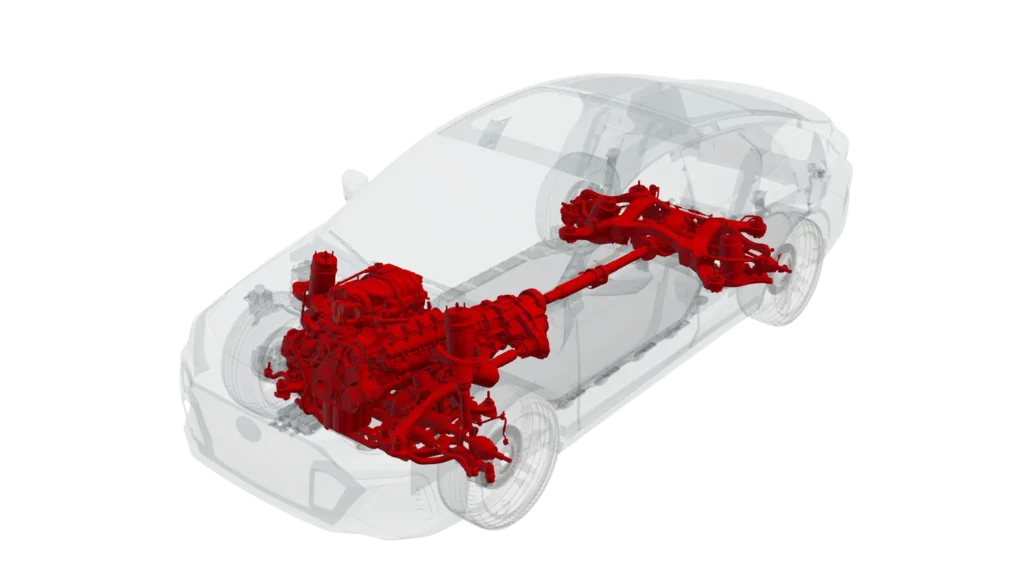

Engineered components used in several automotive applications

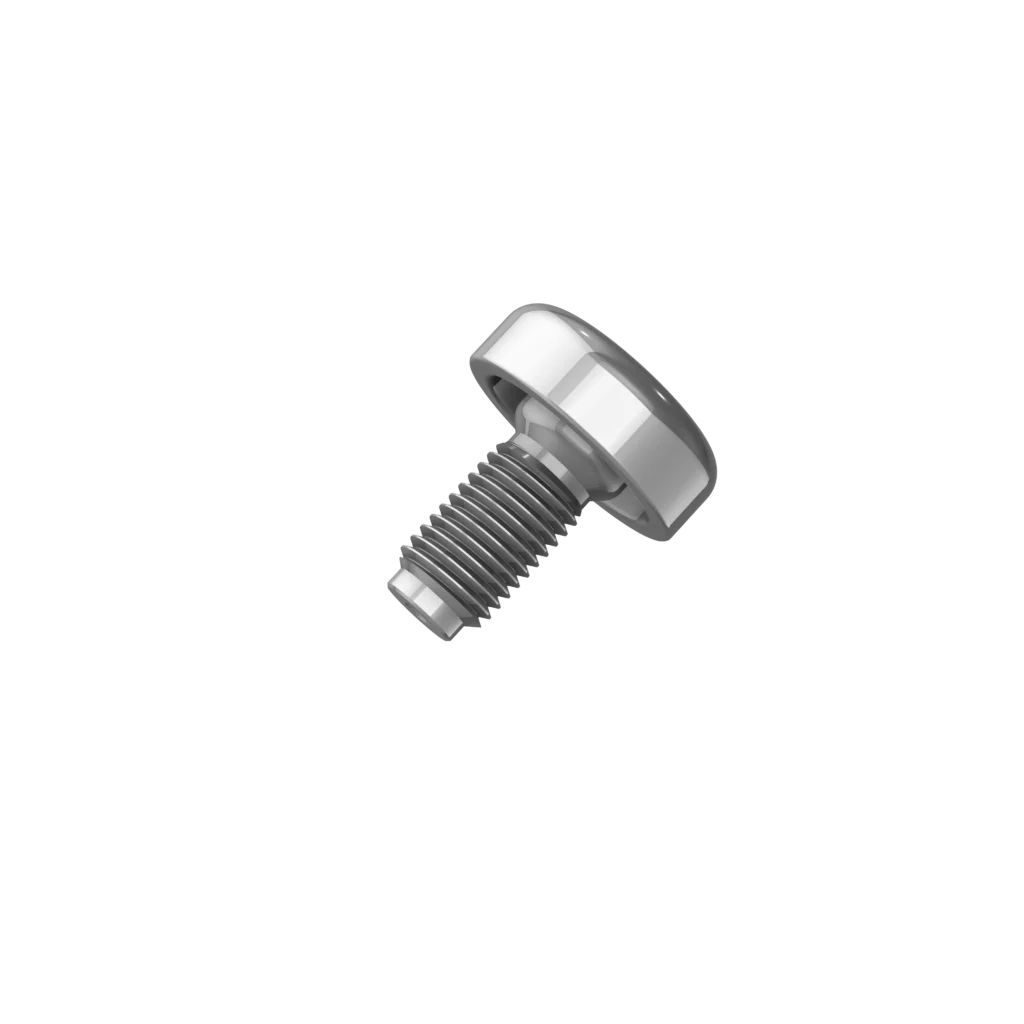

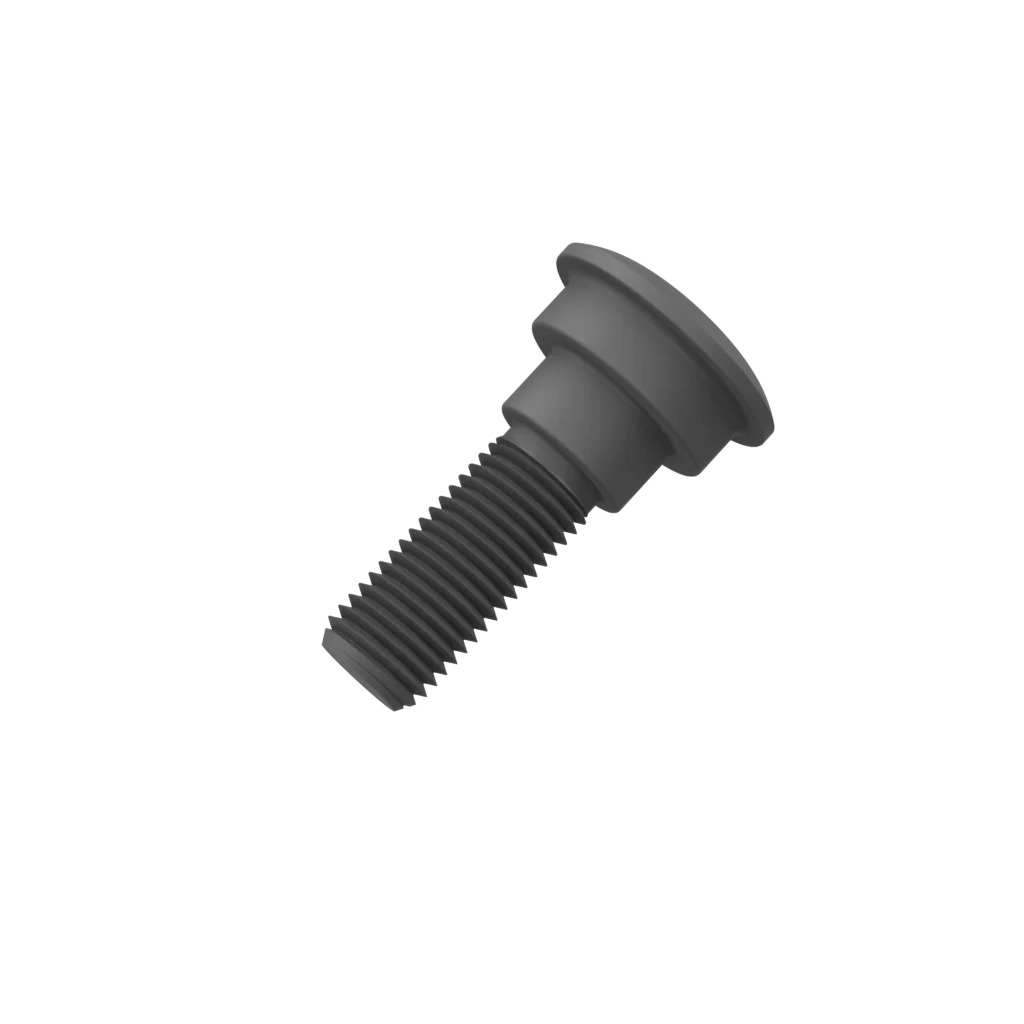

Bell Screw

Main properties

•Size range M10

Property class: 8.8 – 10.9

Patch application can be managed to guarantee thread locking performances

Competencies

• Optimized forging process to obtain the special head shape

Dedicated controls to guarantee high quality levels

Applications

• Standardized solution for seating frames fastenings

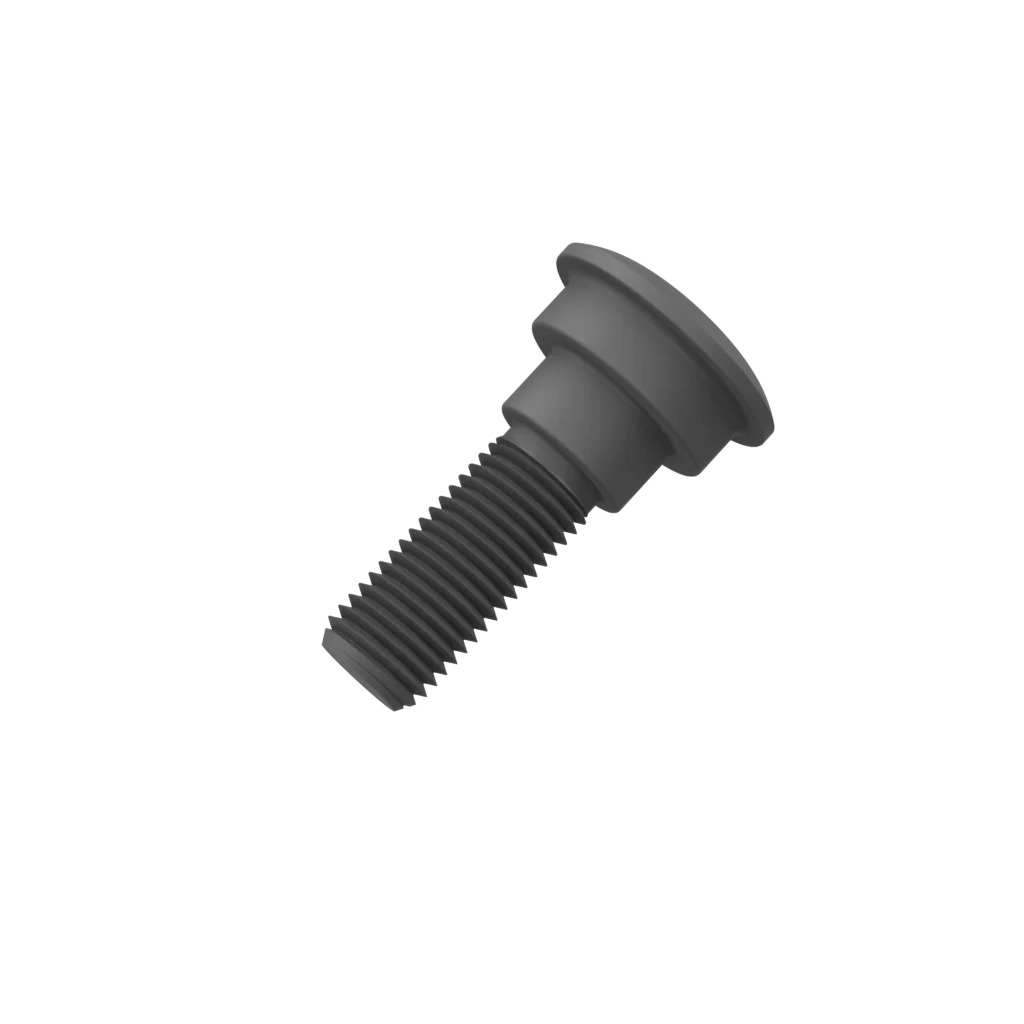

Shoulder Bolt

Main properties

• Size range M6 – M16

• Property class: 8.8 – 12.9

• Coatings: Zink Flake or Electrolytic

Competencies

• Calibrated shoulder realized directly by forging

• Different head styles are available

• Knurled version available

Applications

• Safety belt joints

• Seating systems

• All specific use where the screws has a not simple handling during the tightening activities

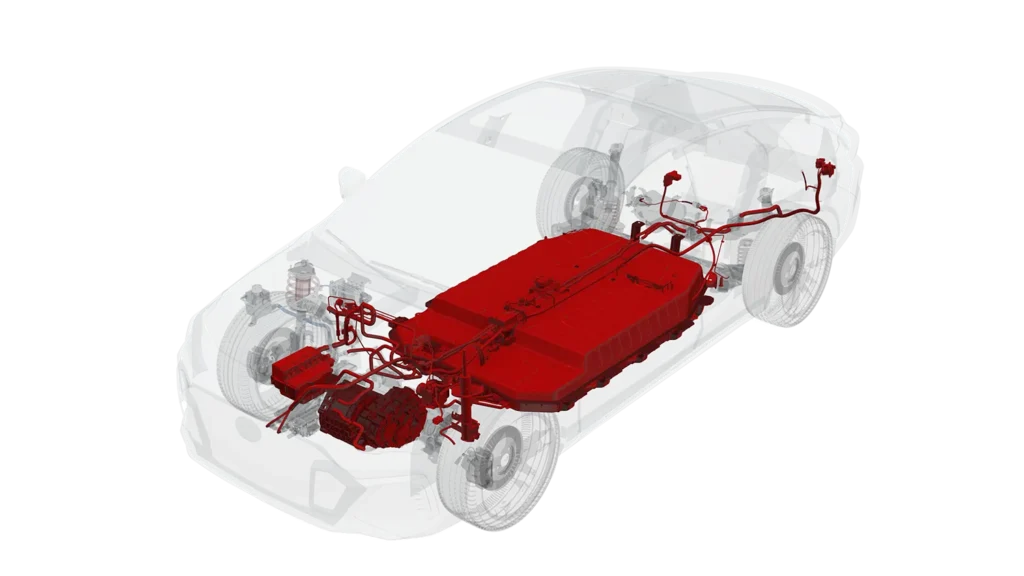

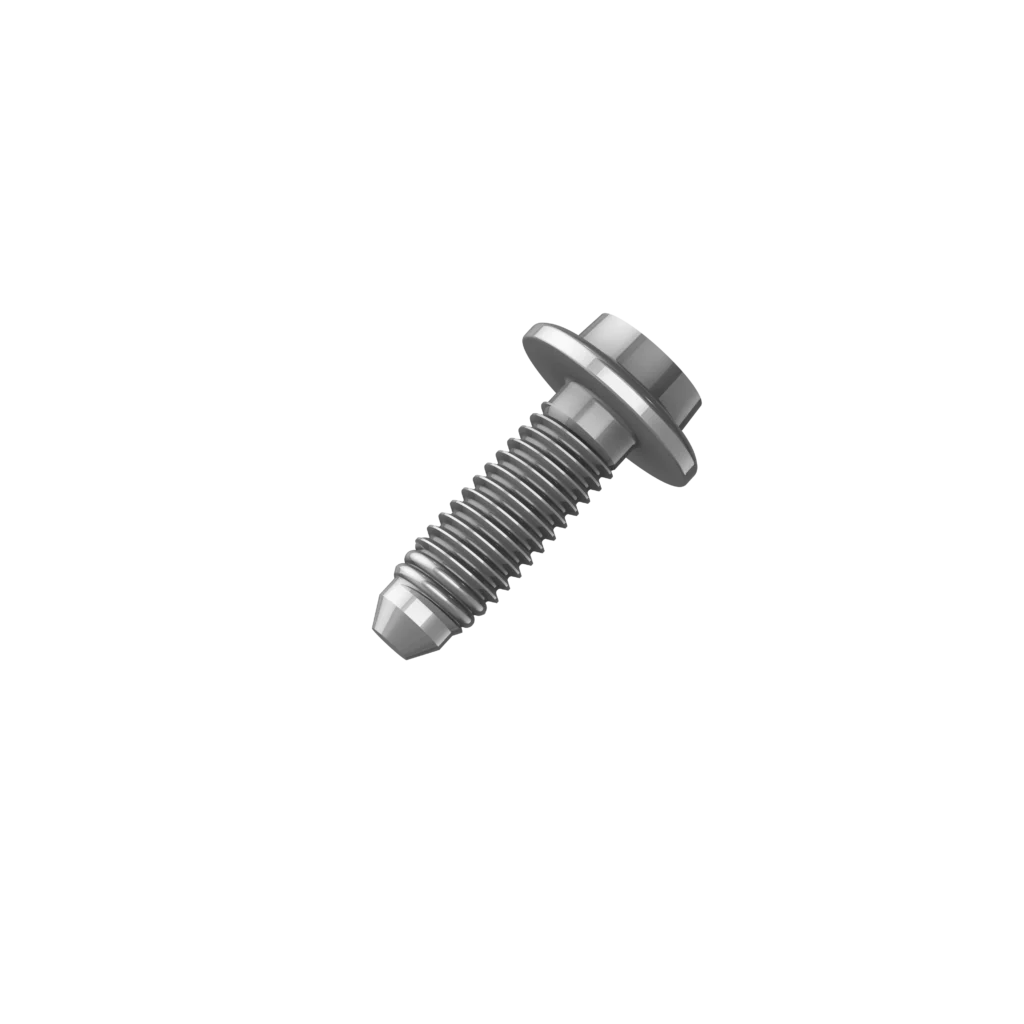

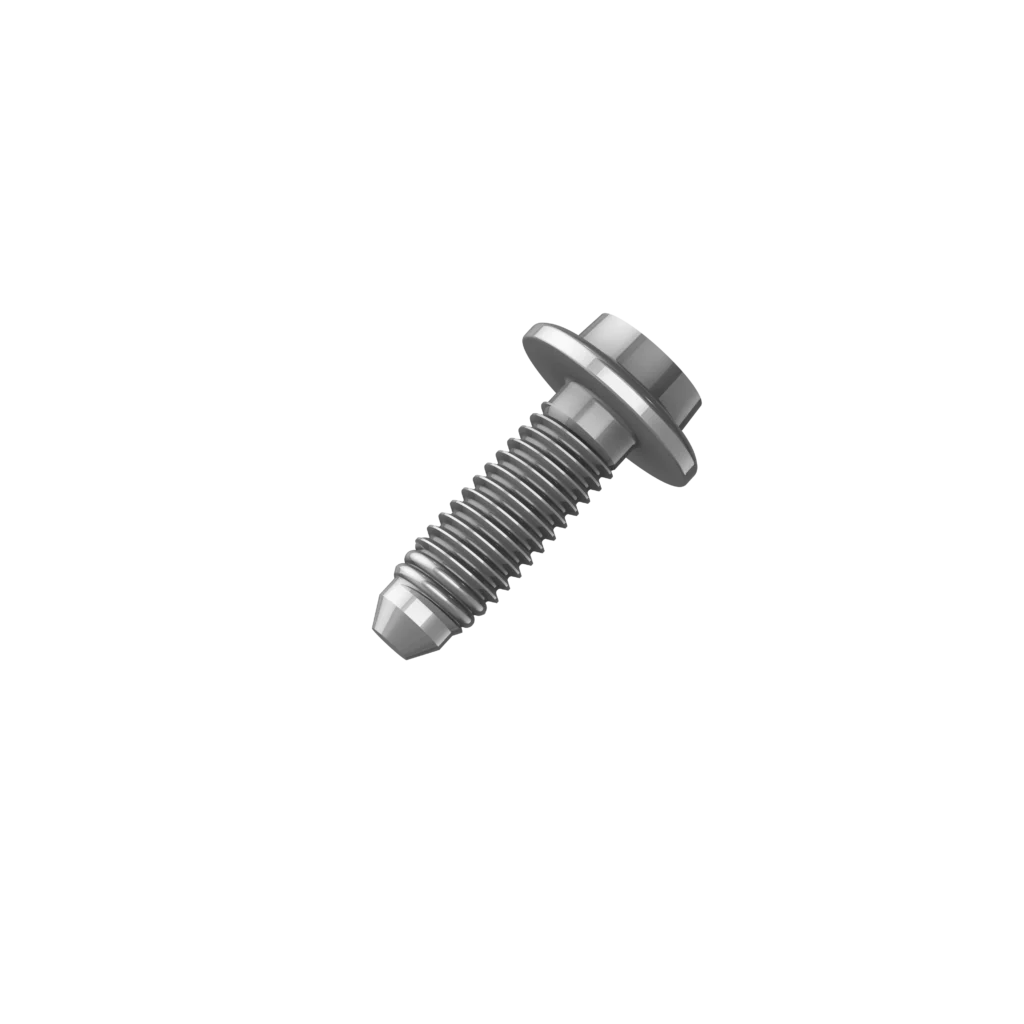

Weld Stud

Main properties

• Size range M5 – M8

• Compatibility with existing welding equipments

Competencies

• Optimized geometry to simplify the production process

Applications

• Fastening systems for BIW applications

• Grounding studs

Engineered components used in several automotive applications

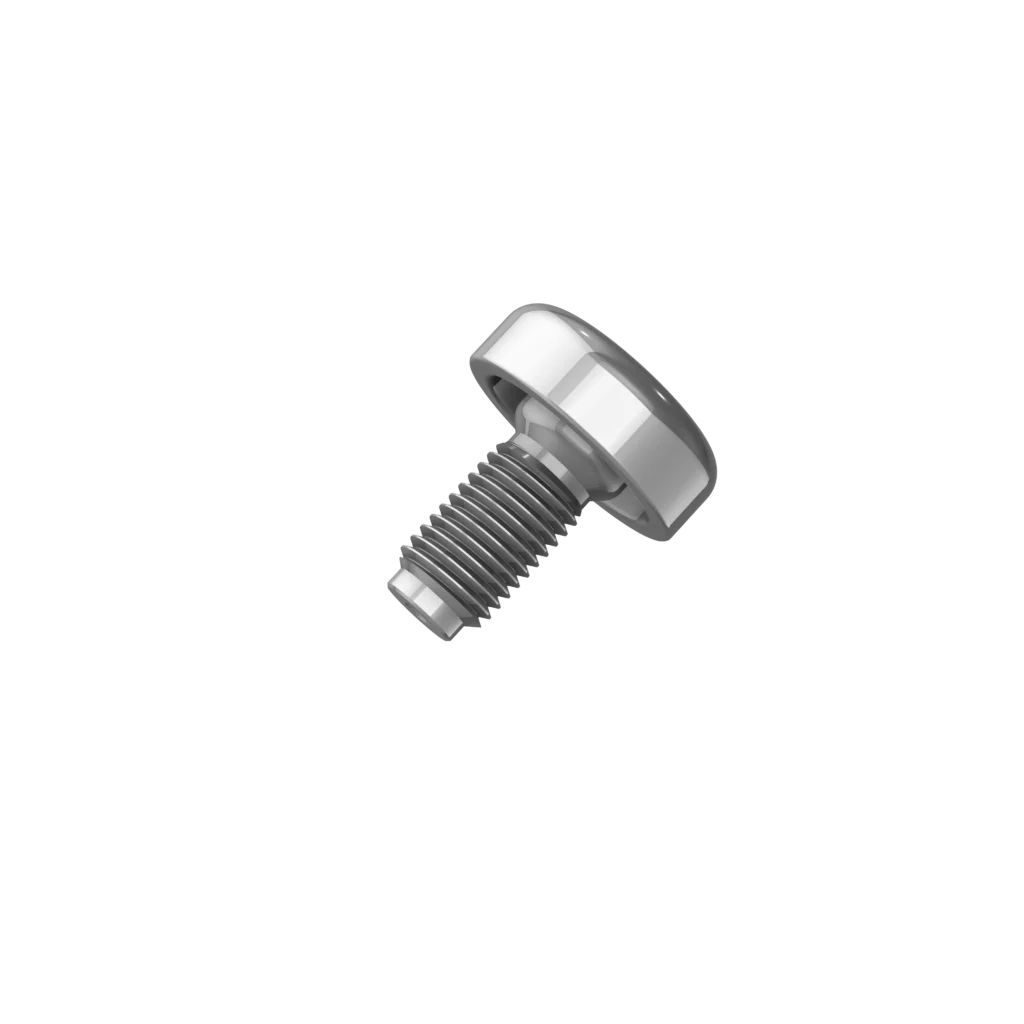

Bell Screw

Main properties

•Size range M10

Property class: 8.8 – 10.9

Patch application can be managed to guarantee thread locking performances

Competencies

• Optimized forging process to obtain the special head shape

Dedicated controls to guarantee high quality levels

Applications

• Standardized solution for seating frames fastenings

Shoulder Bolt

Main properties

• Size range M6 – M16

• Property class: 8.8 – 12.9

• Coatings: Zink Flake or Electrolytic

Competencies

• Calibrated shoulder realized directly by forging

• Different head styles are available

• Knurled version available

Applications

• Safety belt joints

• Seating systems

• All specific use where the screws has a not simple handling during the tightening activities

Weld Stud

Main properties

• Size range M5 – M8

• Compatibility with existing welding equipments

Competencies

• Optimized geometry to simplify the production process

Applications

• Fastening systems for BIW applications

• Grounding studs

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.