We offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements

Agrati produces over 5 million screws every day, primarily dedicated to the automotive market. In order to ensure high standards of quality, nearly all processes, such as tooling, wire drawing, cold forging, thread rolling, and heat treatments, are carried out internally or, in some specific cases, through qualified suppliers. This allows us to offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements.

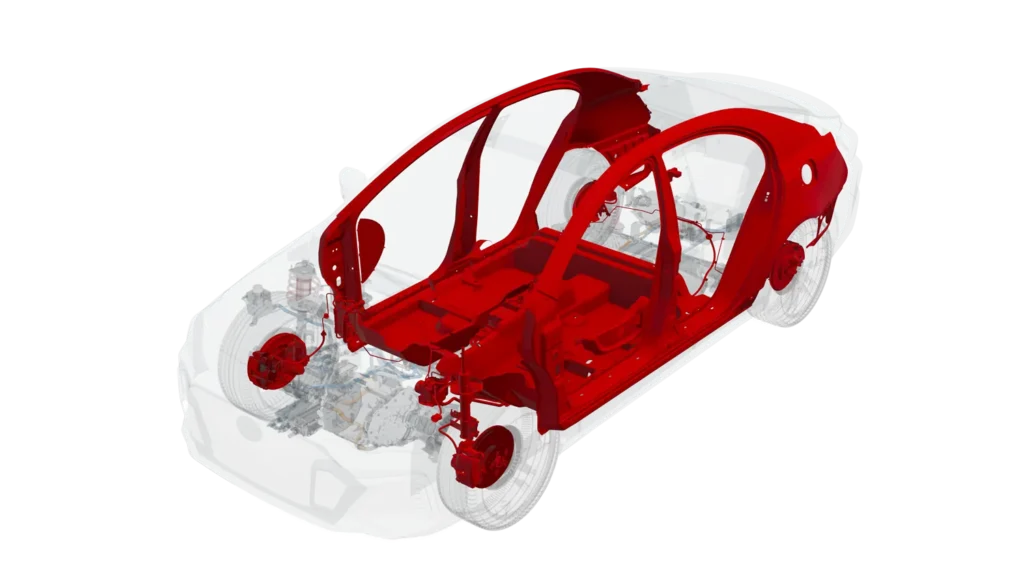

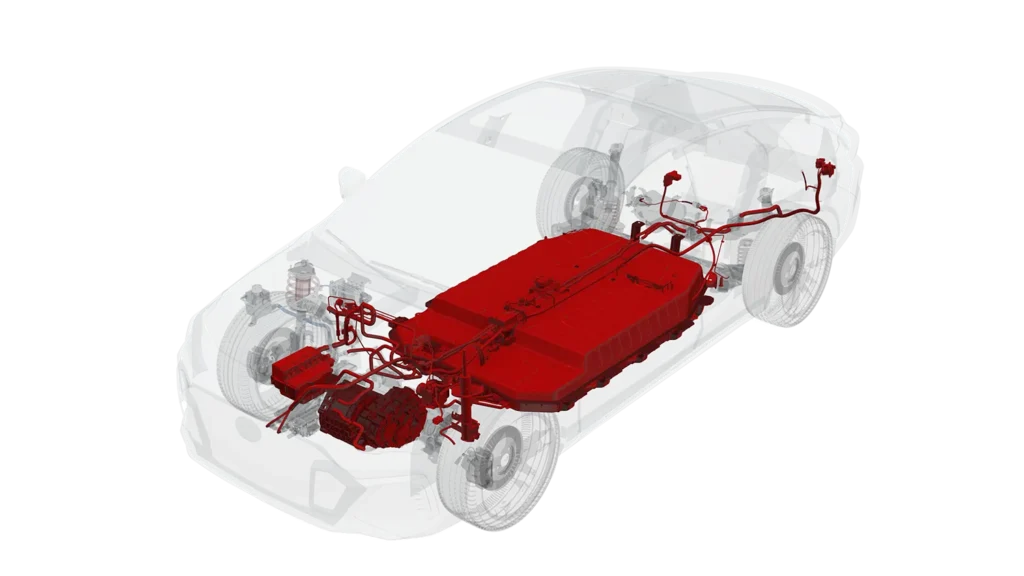

Engineered components used in several automotive applications

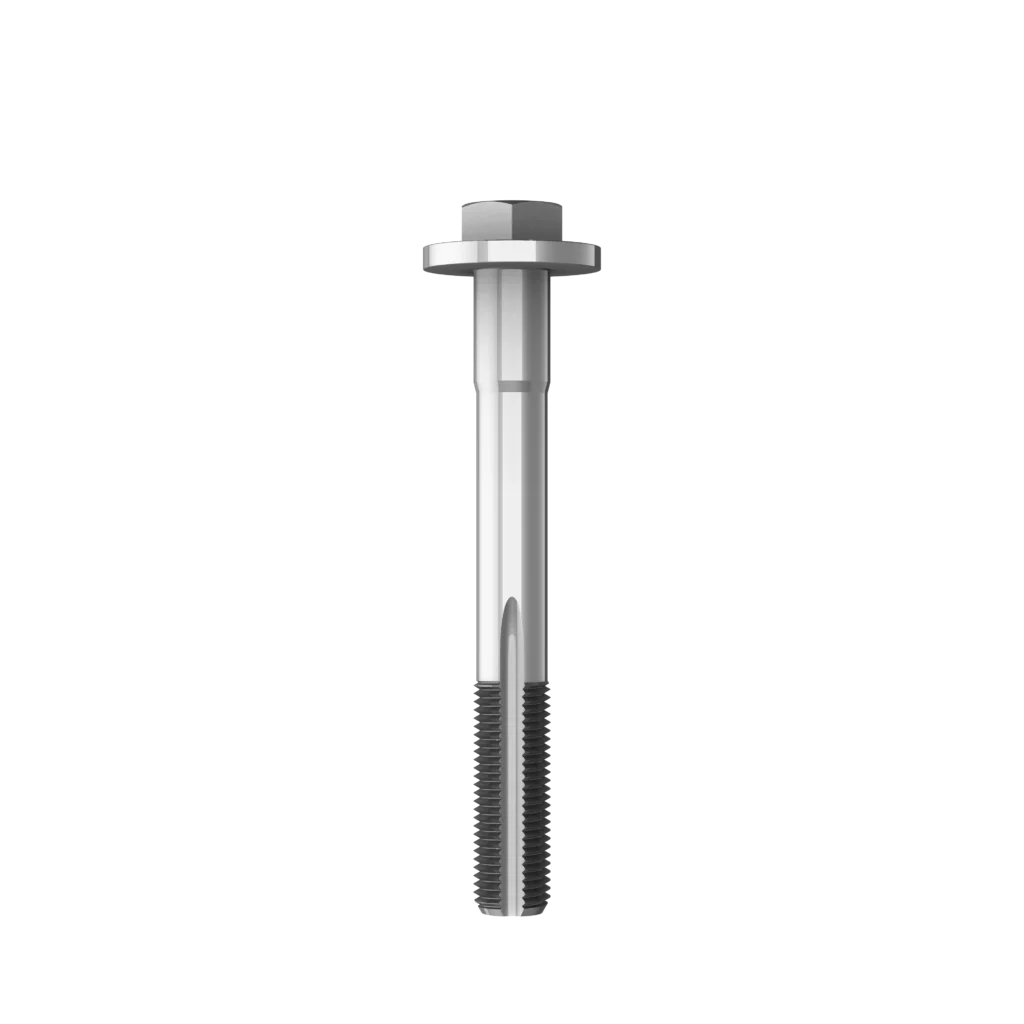

Cambolt

Main properties

• Size range M10 to M20

• Washer Ø 32-45 mm

• Eccentricity 2.5-5 mm

• Property class : 8.8-12.9

• Coating : Zink Flake or others according to request

Competencies

• Optimized design: assembled washer and milled groove

• Alternative versions (with forged grooves and integrated washer)

• Full systems with complementary products like counter-washer and nut can be supplied

Applications

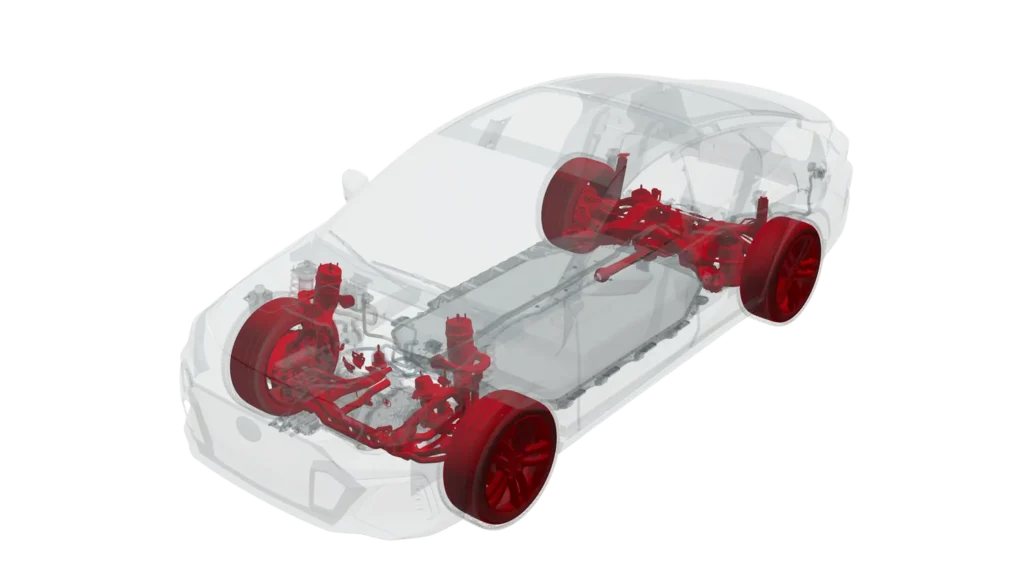

• Suspension systems

• Adjustment of camber /toe angle

• Multilink Systems

• Light truck

Wheel Bolt

Main properties

• Size range M12-M18

• Property class: 8.8-10.9 (special characteristics according to specific request can be managed)

• Special coatings, with strong rust resistance, developed internally by Agrati, in light or black finishing

Competencies

• Wheel bolt design can be realized with single piece design or with conical/spherical captive washer

• Special coatings or finishings can be provided

• Stability and reliability on multi-tightening can be guaranteed

• Aesthetic properties can be evaluated

Applications

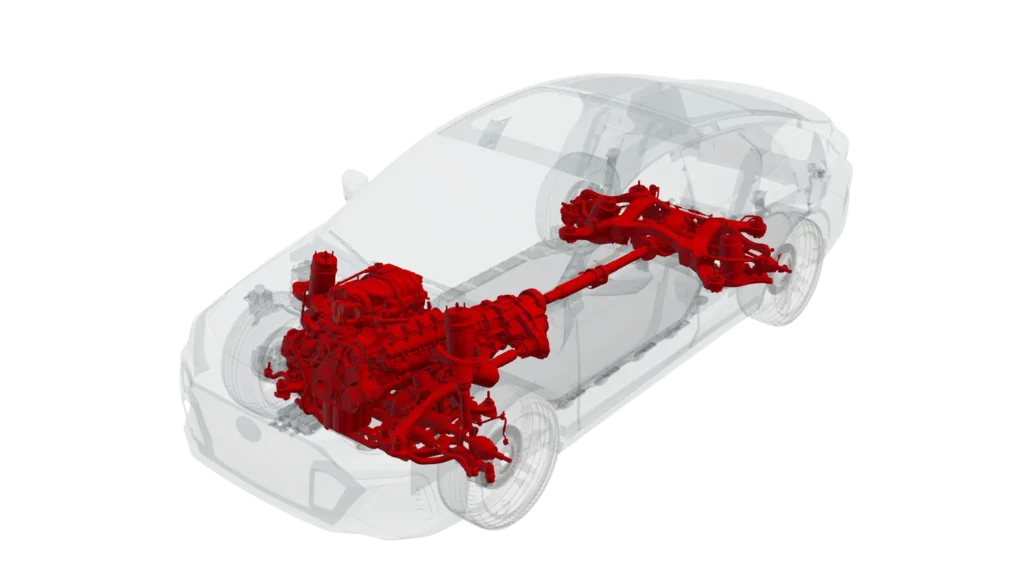

• Fixations of wheel rims to hub

• Specific stud for big dimensions of wheels

Chassis Bolt

Main properties

• Size range M8 to M20

• Single-piece parts or bolt with captive washers

• Property class: 8.8 – 12.9

Competencies

• High strength bolts with customized requirements

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance

Applications

• Suspensions

• Steering system

• Brakes

Engineered components used in several automotive applications

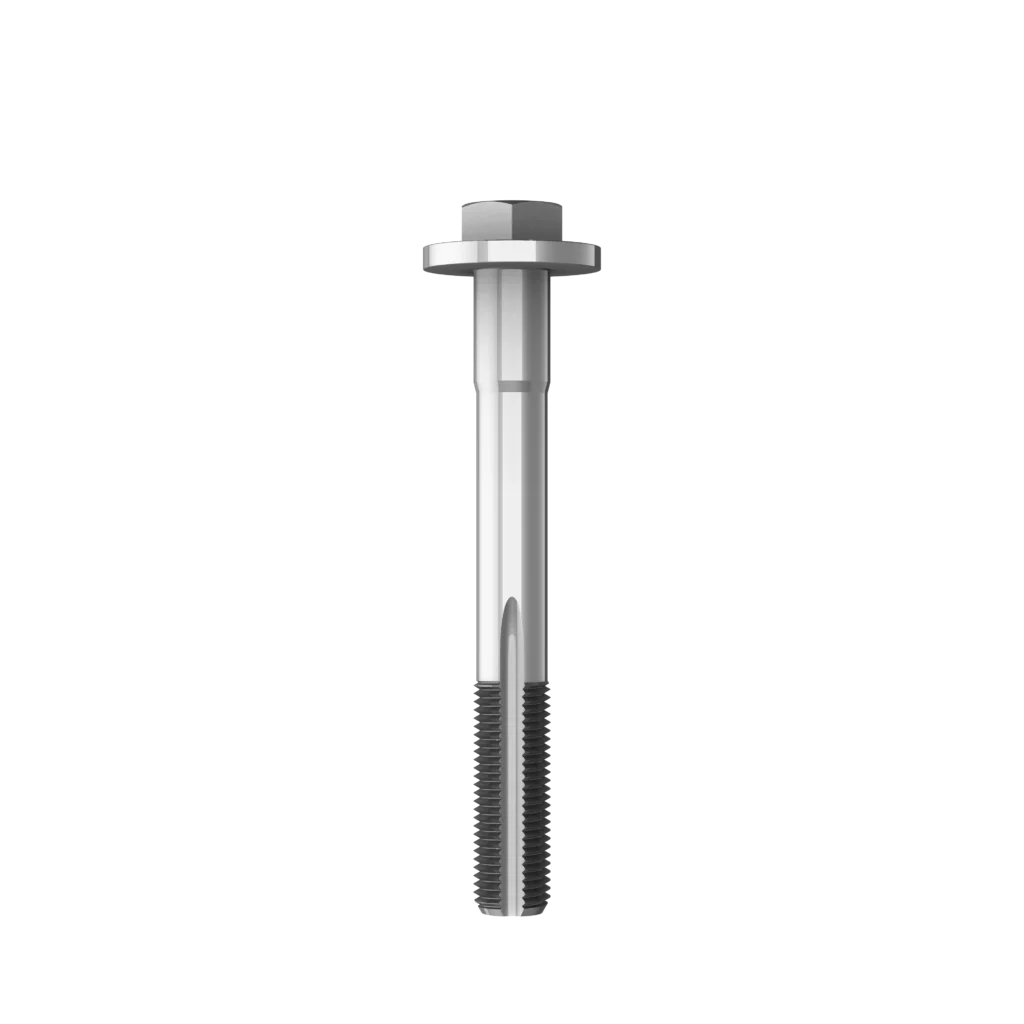

Cambolt

Main properties

• Size range M10 to M20

• Washer Ø 32-45 mm

• Eccentricity 2.5-5 mm

• Property class : 8.8-12.9

• Coating : Zink Flake or others according to request

Competencies

• Optimized design: assembled washer and milled groove

• Alternative versions (with forged grooves and integrated washer)

• Full systems with complementary products like counter-washer and nut can be supplied

Applications

• Suspension systems

• Adjustment of camber /toe angle

• Multilink Systems

• Light truck

Wheel Bolt

Main properties

• Size range M12-M18

• Property class: 8.8-10.9 (special characteristics according to specific request can be managed)

• Special coatings, with strong rust resistance, developed internally by Agrati, in light or black finishing

Competencies

• Wheel bolt design can be realized with single piece design or with conical/spherical captive washer

• Special coatings or finishings can be provided

• Stability and reliability on multi-tightening can be guaranteed

• Aesthetic properties can be evaluated

Applications

• Fixations of wheel rims to hub

• Specific stud for big dimensions of wheels

Chassis Bolt

Main properties

• Size range M8 to M20

• Single-piece parts or bolt with captive washers

• Property class: 8.8 – 12.9

Competencies

• High strength bolts with customized requirements

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance

Applications

• Suspensions

• Steering system

• Brakes

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.