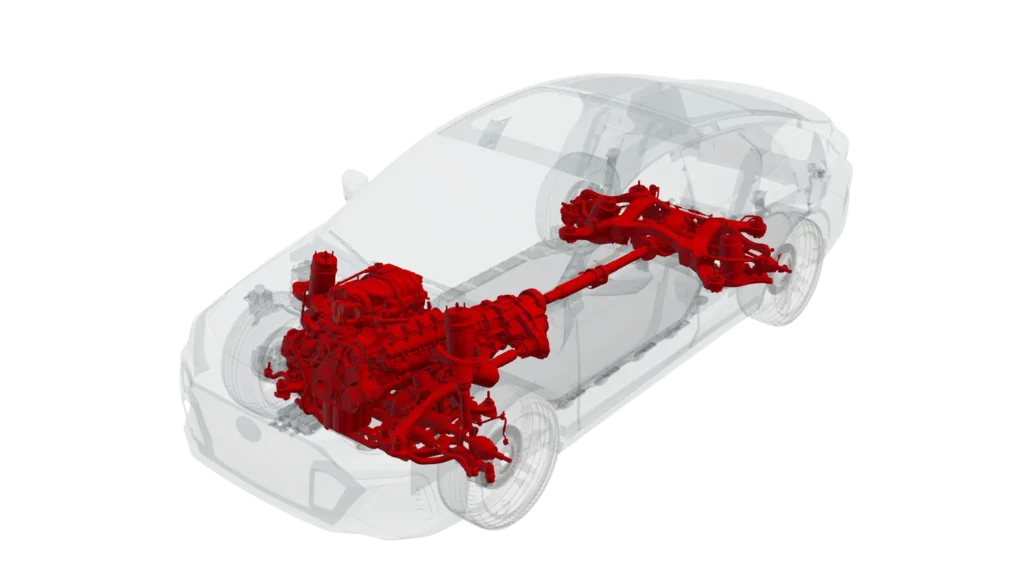

Advanced Form Parts are engineered components that can be manufactured with the core Agrati Group technology: the cold forging process.

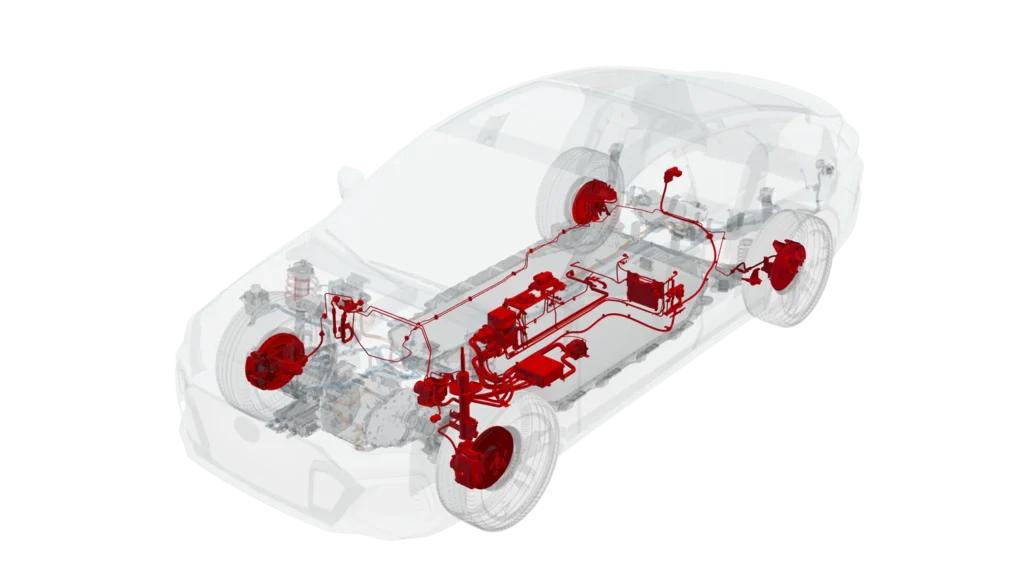

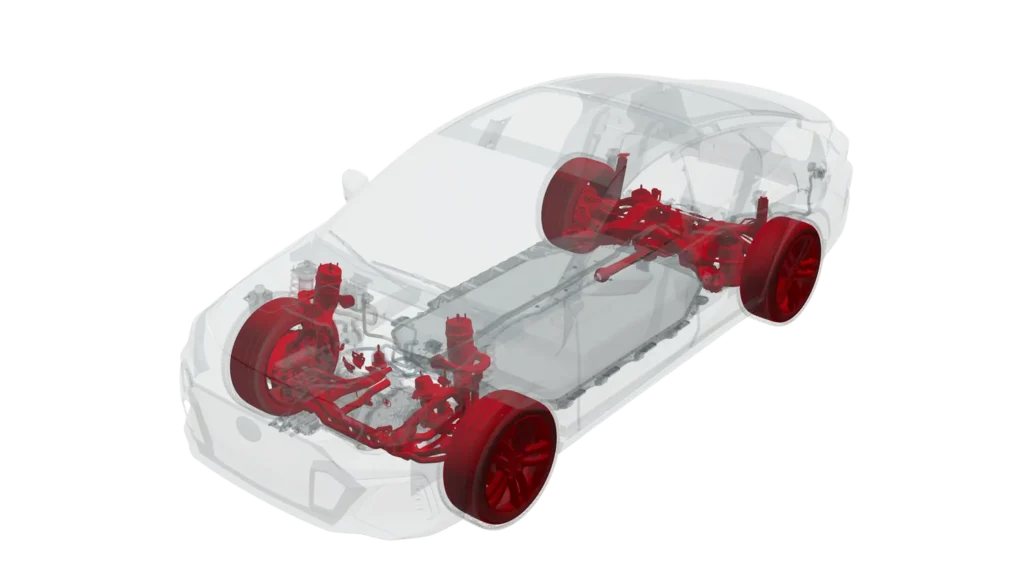

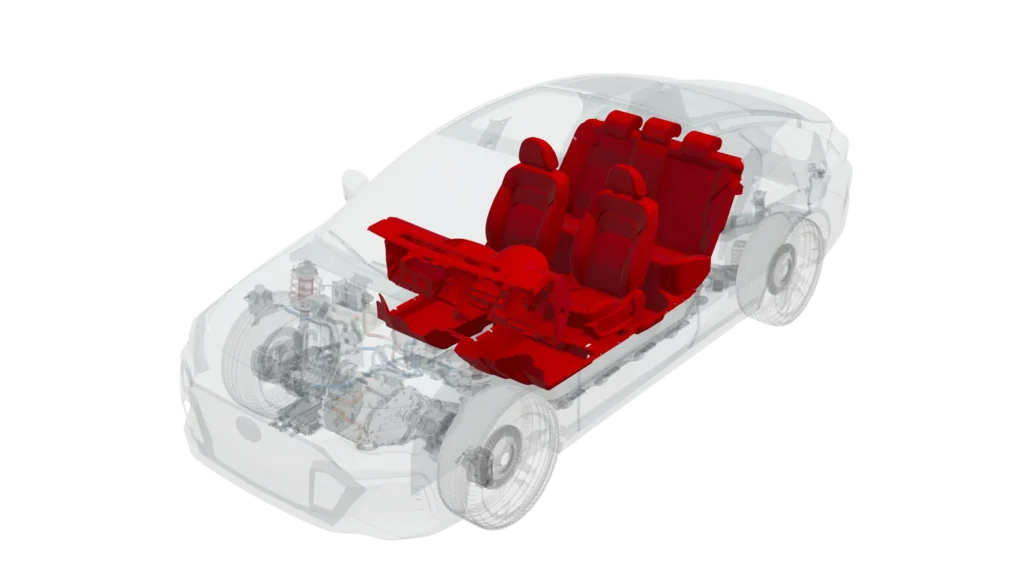

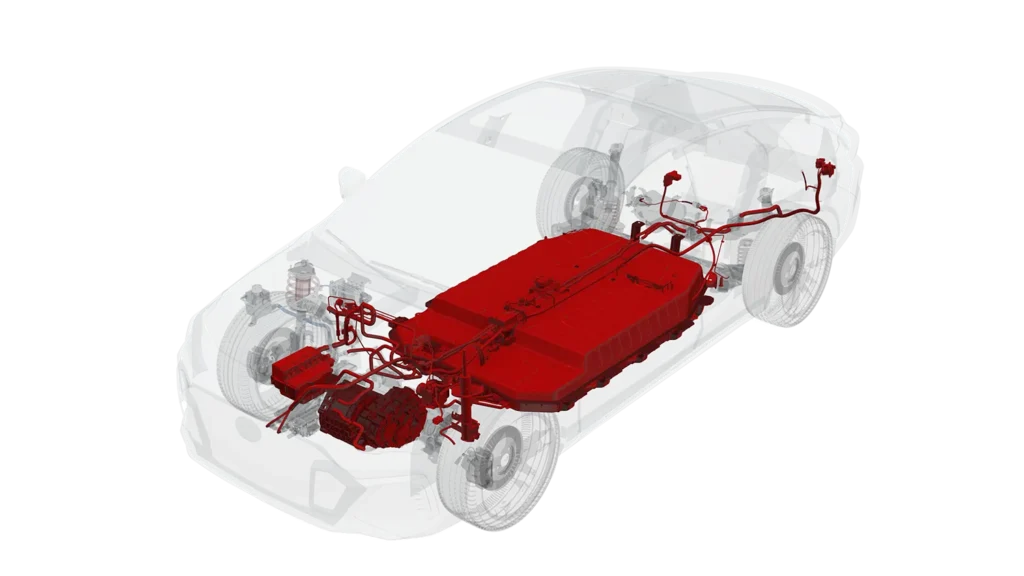

These parts are used in several fields of automotive applications:

- chassis

- seatings

- brakes and safety systems

- engine

- powertrain & driveline systems

These are products manufactured according to strict customer specifications.

Dedicated control plans during production and the ability to do 100% sorting before packaging guarantee the complete fulfilment of quality requirements.

Engineered components used in several automotive applications

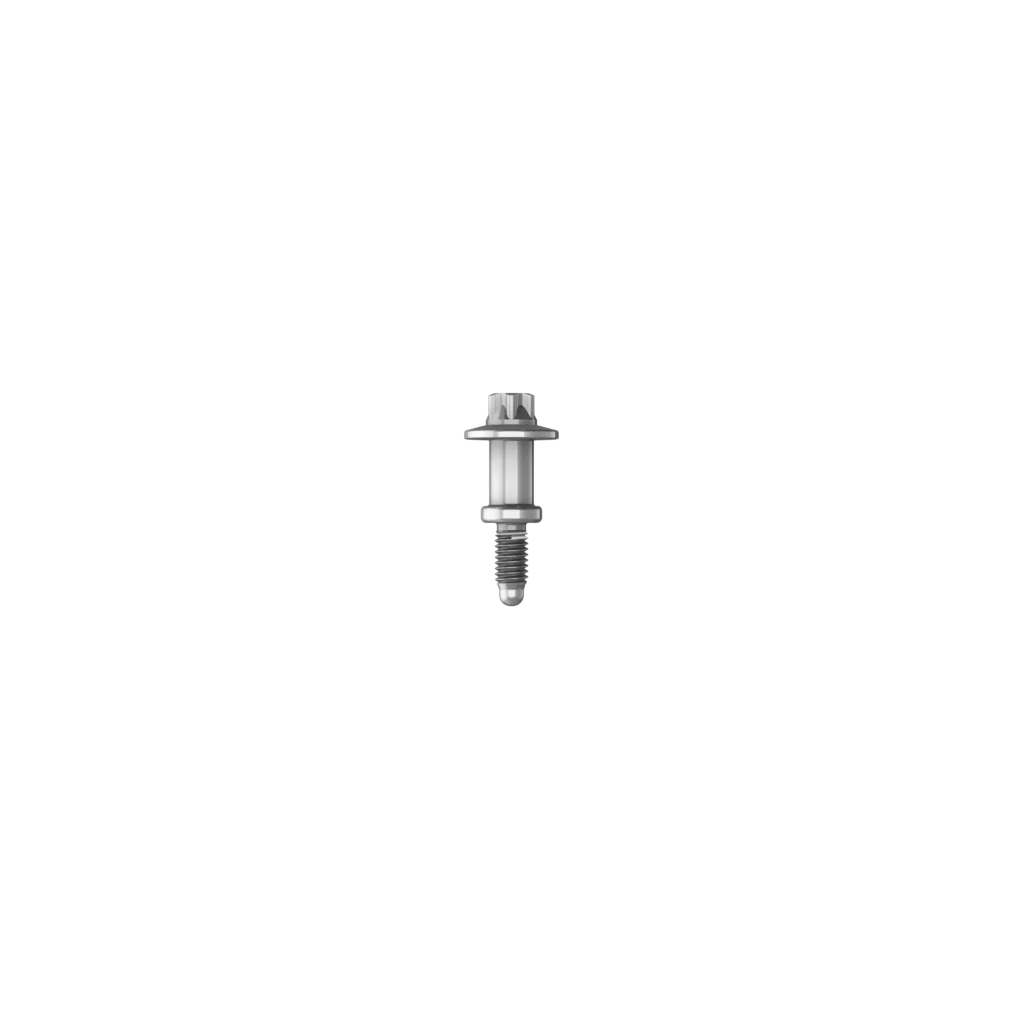

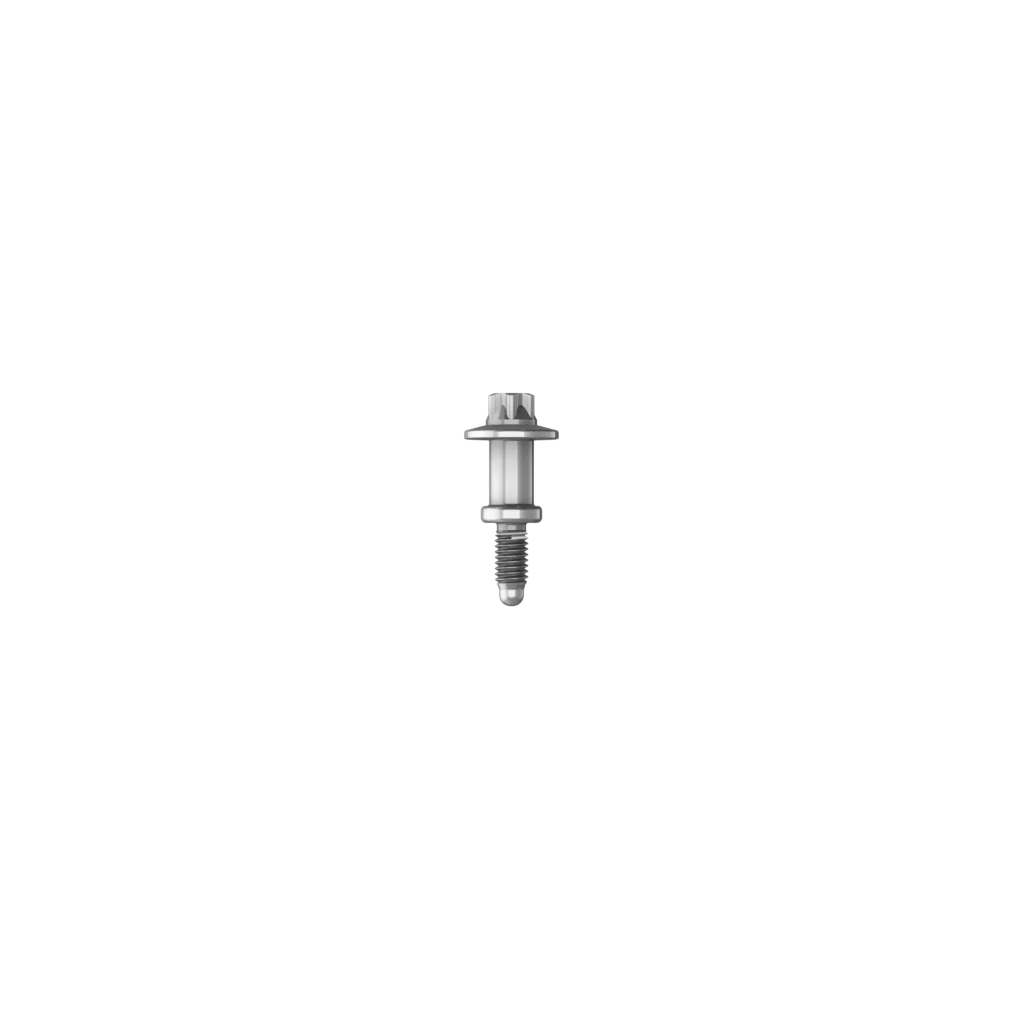

Collar Screw

Competencies

• Smart design for multi-performances in one component

• Geometry design suitable for assembly process

• Economic competitiveness

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

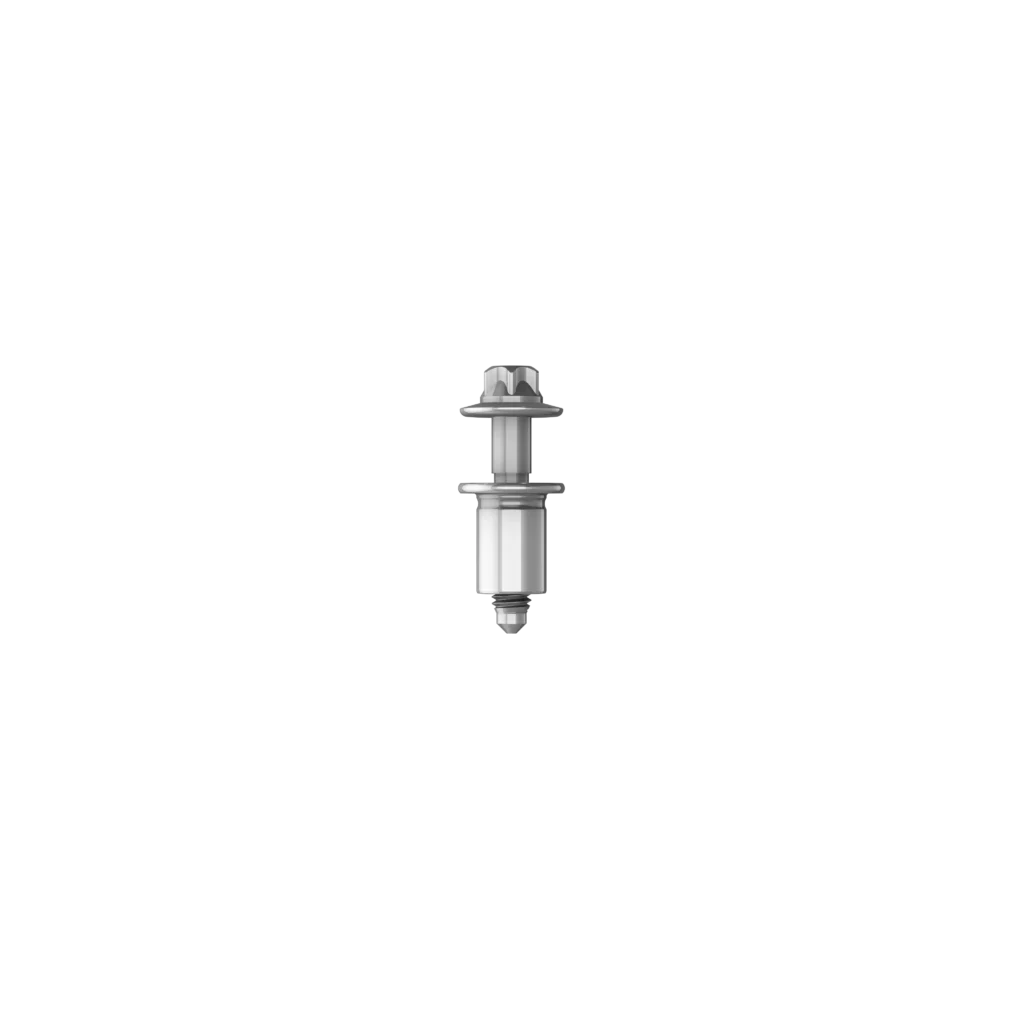

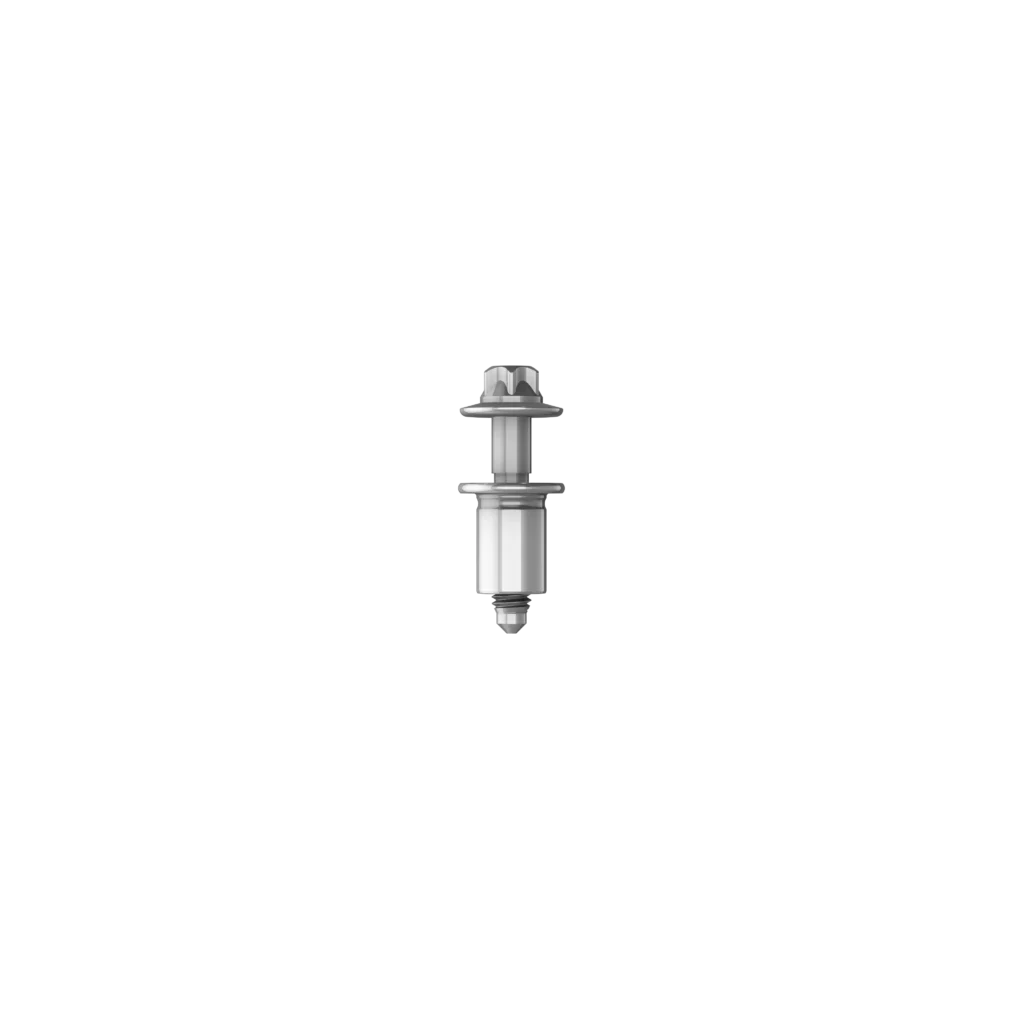

Captive Solution

Competencies

• Smart design for multi-performances

• Geometry design suitable for assembly process

• Final Assembly efficiency improvement

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

• Various solutions for screw/sleeve assembly

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

• Automatic assembly lines

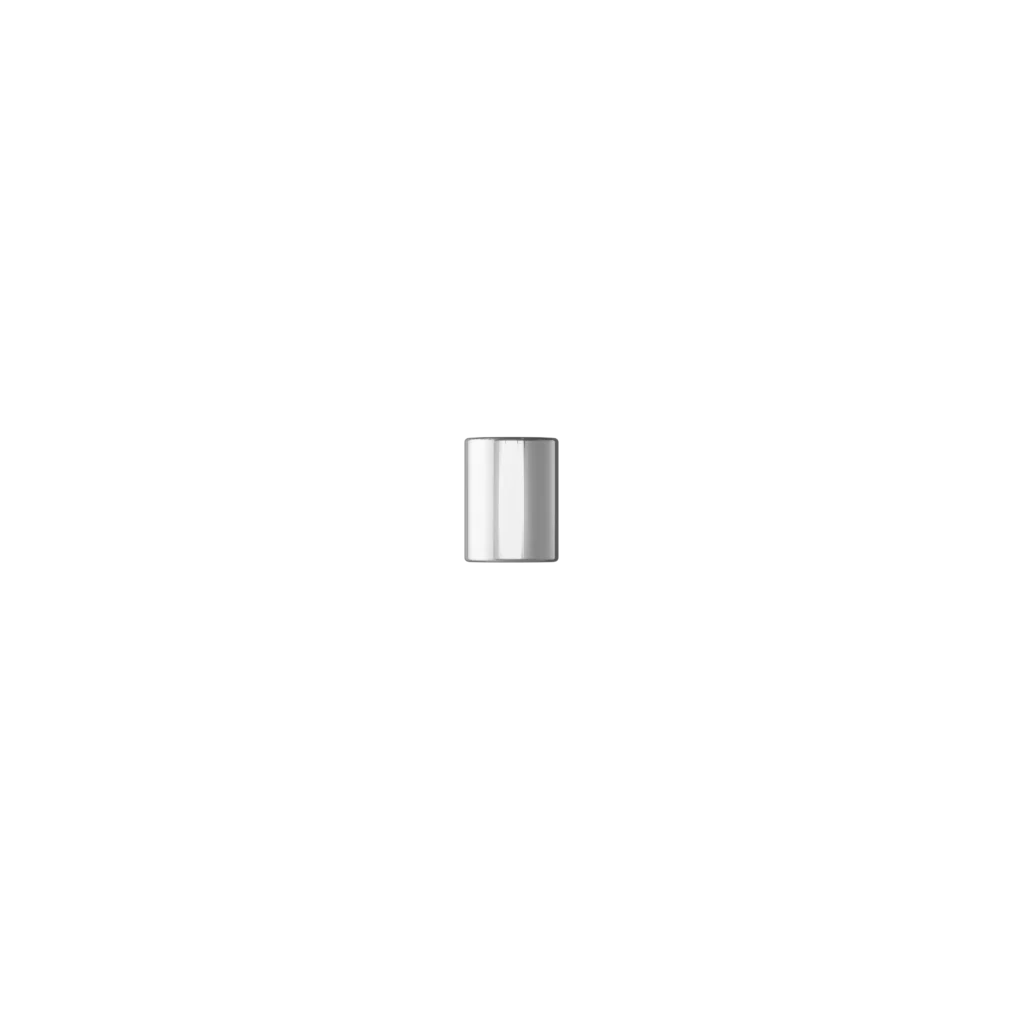

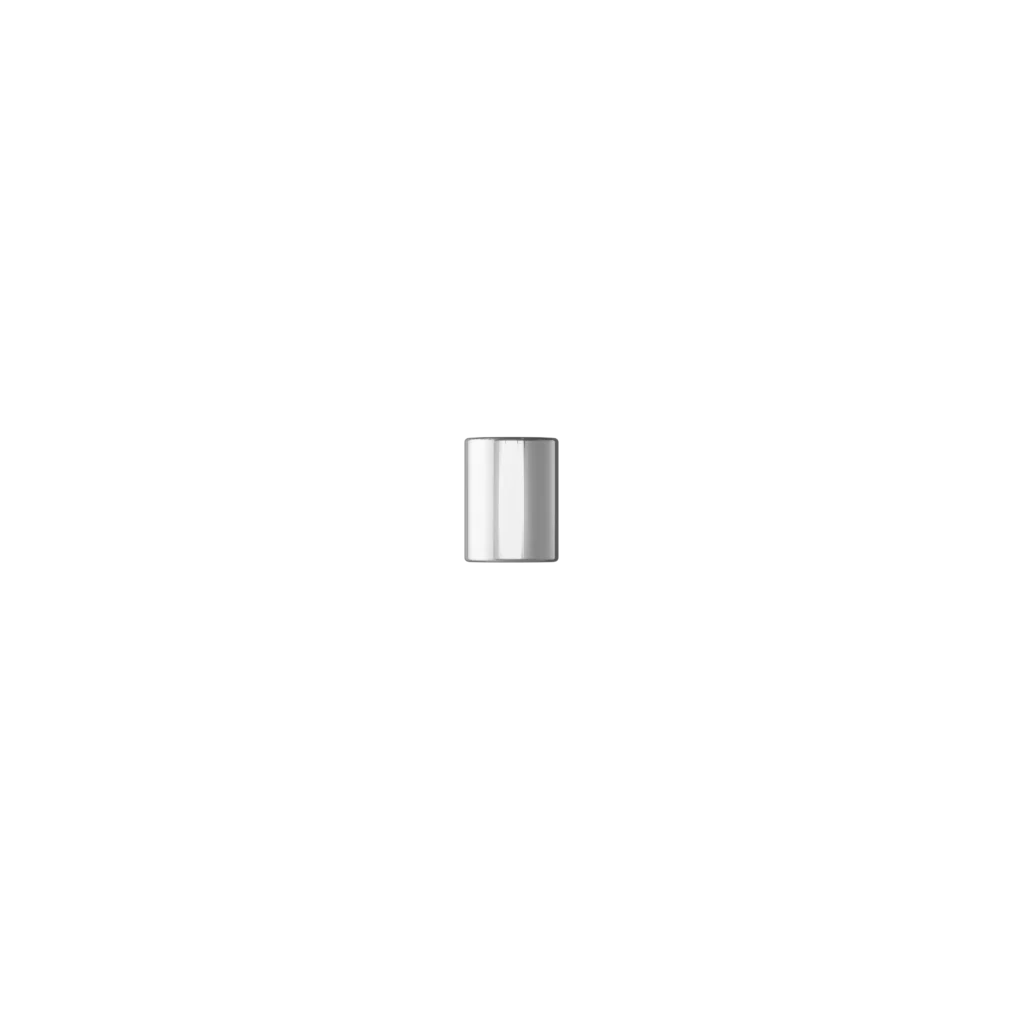

Sleeve

Competencies

• Great control on tolerances

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness

Main properties

• Size range from Ø 5 to 40 mm

• Height tolerance up to 0.05 mm (ore less with grinding)

• Diameter tolerances up to 0.05 mm

• Material: Low Carbon Steel, Alu, Copper, Brass

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

Engineered components used in several automotive applications

Collar Screw

Competencies

• Smart design for multi-performances in one component

• Geometry design suitable for assembly process

• Economic competitiveness

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

Captive Solution

Competencies

• Smart design for multi-performances

• Geometry design suitable for assembly process

• Final Assembly efficiency improvement

Main properties

• Size range M5 to M10

• Property class : 8.8-12.9

• Coating : ZnNi or similar e-coats

• Various solutions for screw/sleeve assembly

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

• Automatic assembly lines

Sleeve

Competencies

• Great control on tolerances

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness

Main properties

• Size range from Ø 5 to 40 mm

• Height tolerance up to 0.05 mm (ore less with grinding)

• Diameter tolerances up to 0.05 mm

• Material: Low Carbon Steel, Alu, Copper, Brass

• Coating : ZnNi or similar e-coats

Applications

• Plastic reinforcement

• Compression limiter

• Plastic fixation on powertrain

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.