Advanced Form Parts are engineered components that can be manufactured with the core Agrati Group technology: the cold forging process.

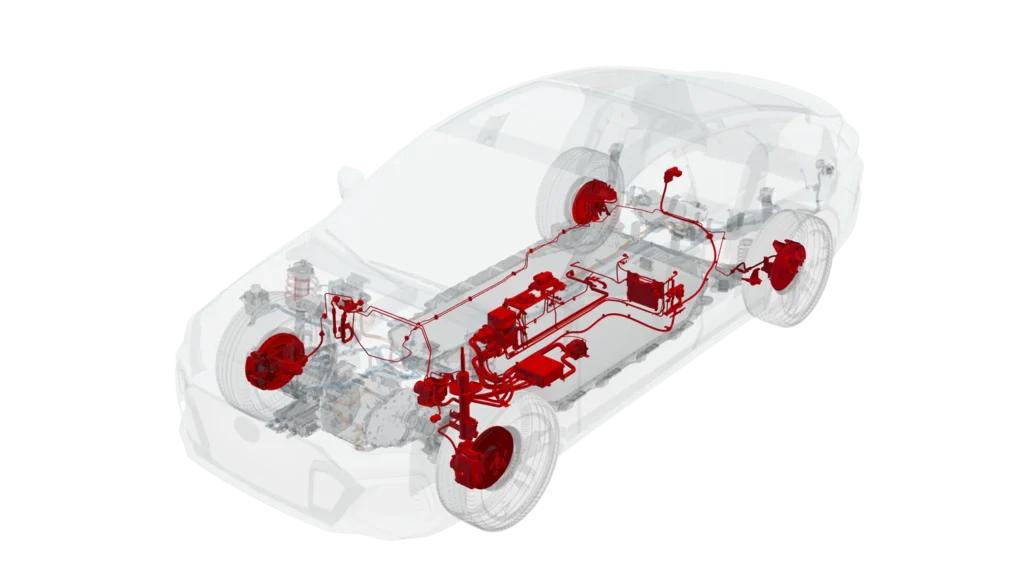

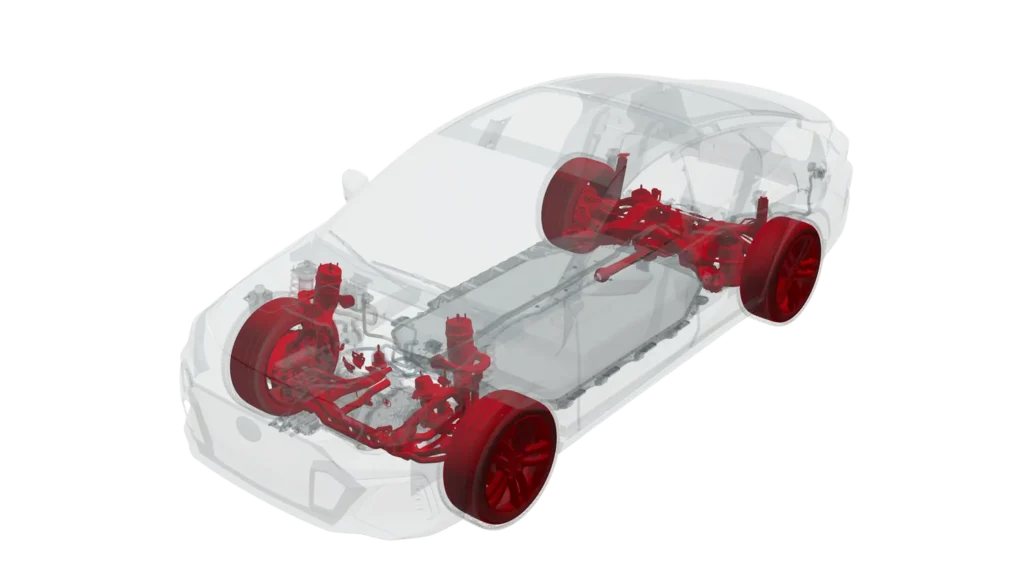

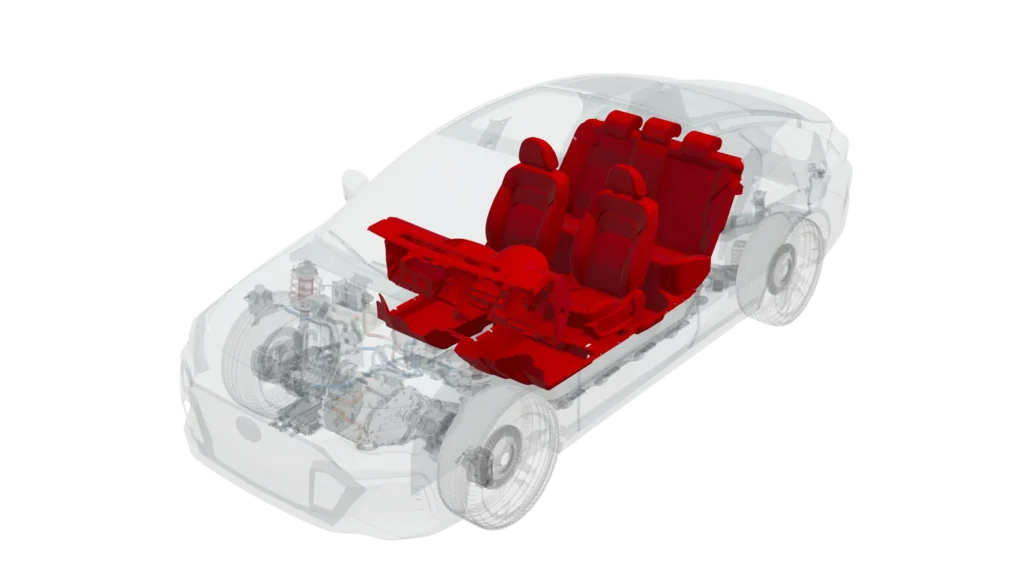

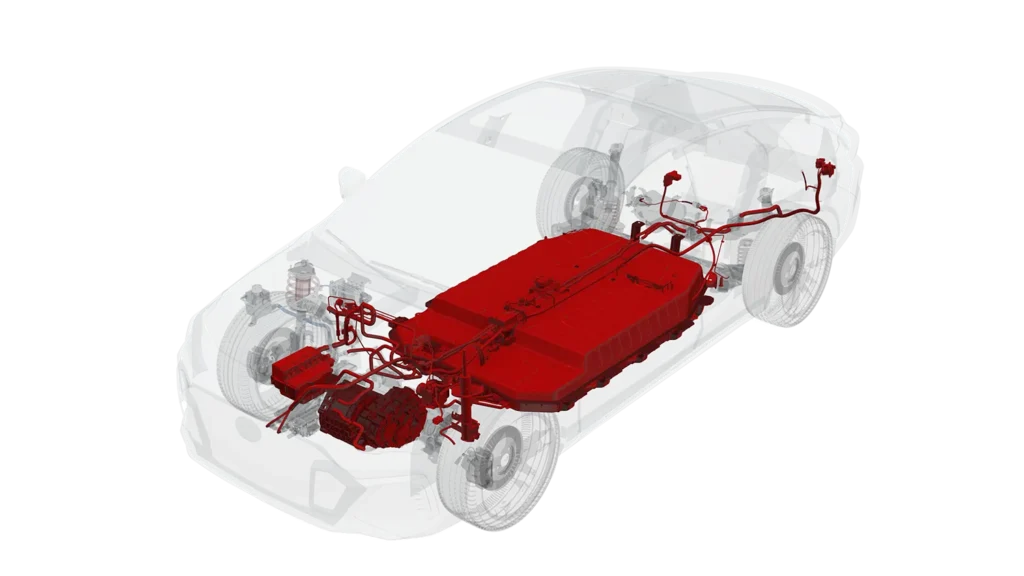

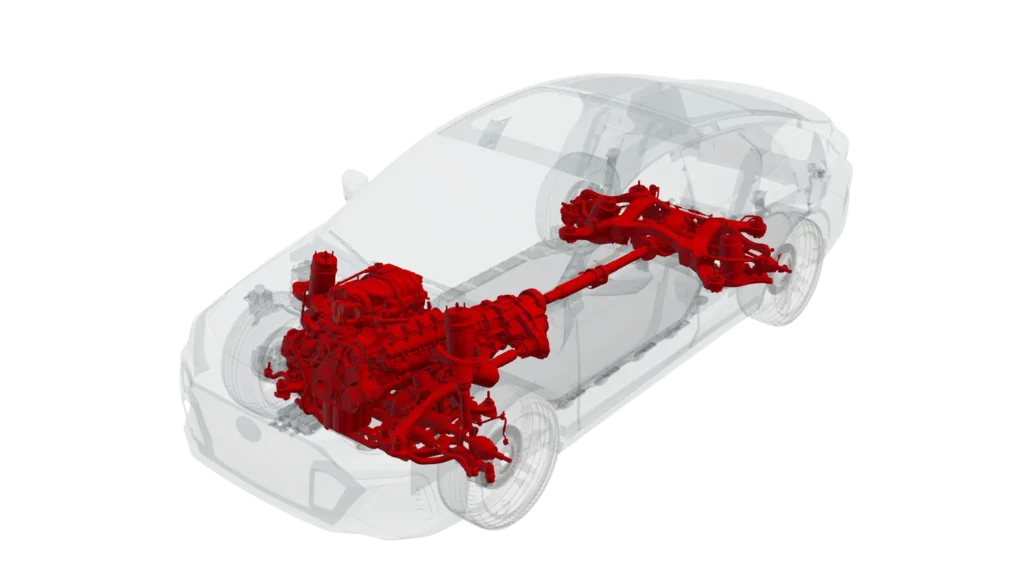

These parts are used in several fields of automotive applications:

- chassis

- seatings

- brakes and safety systems

- engine

- powertrain & driveline systems

These are products manufactured according to strict customer specifications.

Dedicated control plans during production and the ability to do 100% sorting before packaging guarantee the complete fulfilment of quality requirements.

Engineered components used in several automotive applications

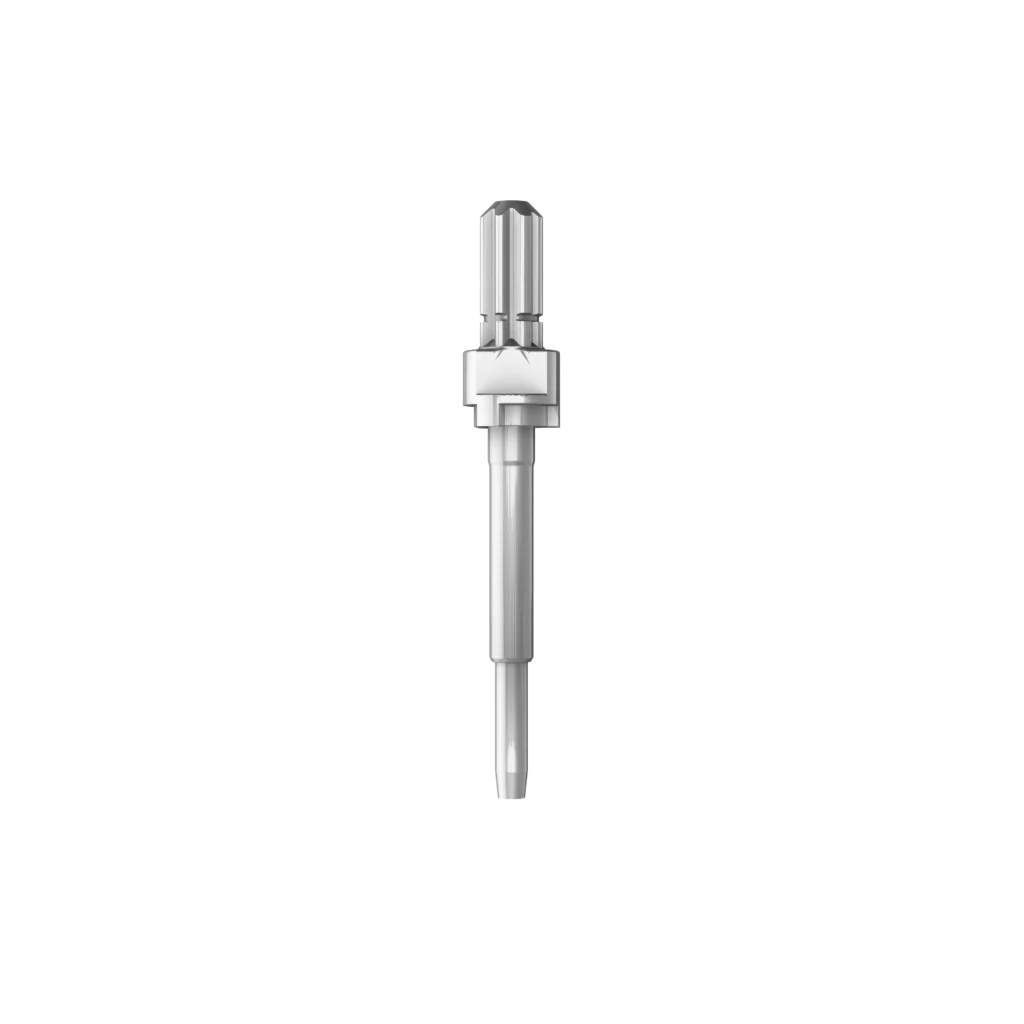

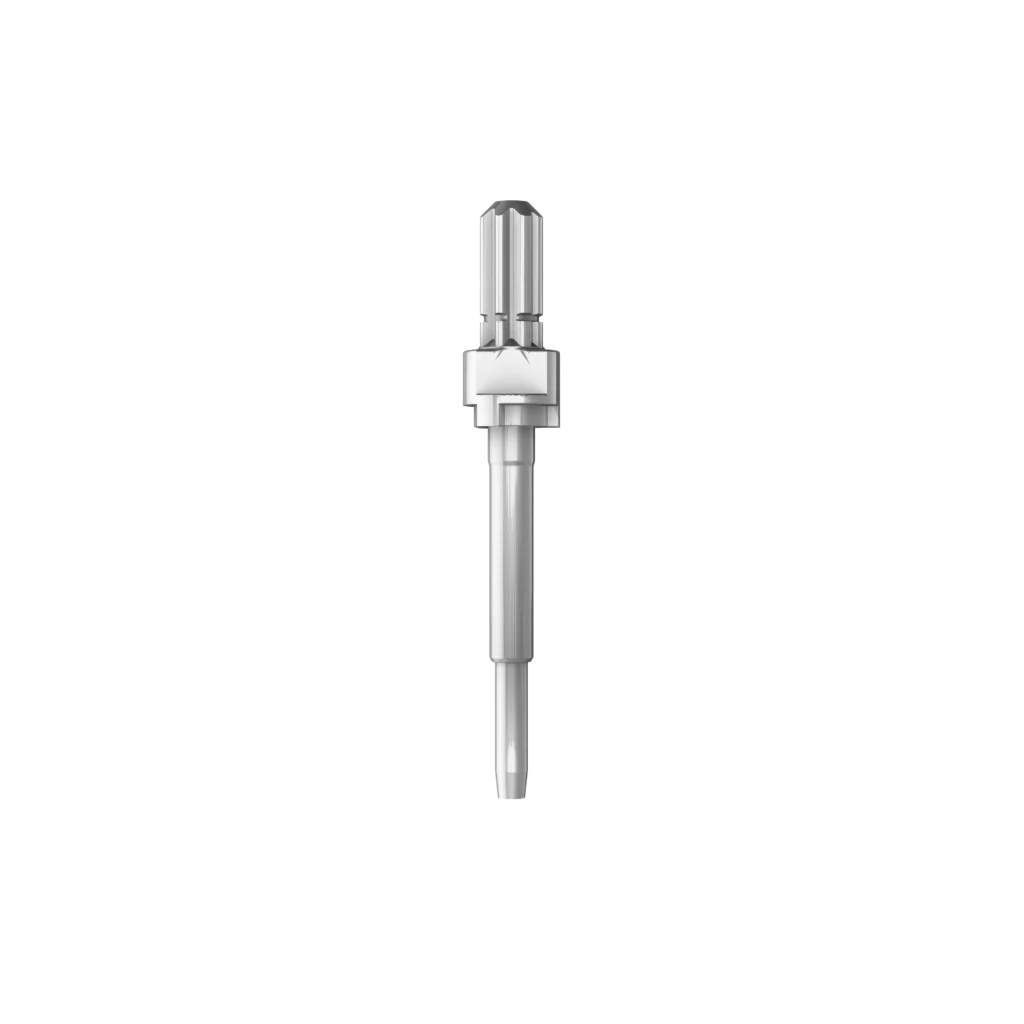

Shaft

Competencies

• Extrusion and fine blanking technology

• Secondary turning operation

• Small size forging machine with long kick out

• Centerless grinding

Main properties

• Slender part

• Corrosion resistance

• Small linearity and concentricity tolerances required

• complex shape

Applications

• Seats regulation

• Armrest regulation

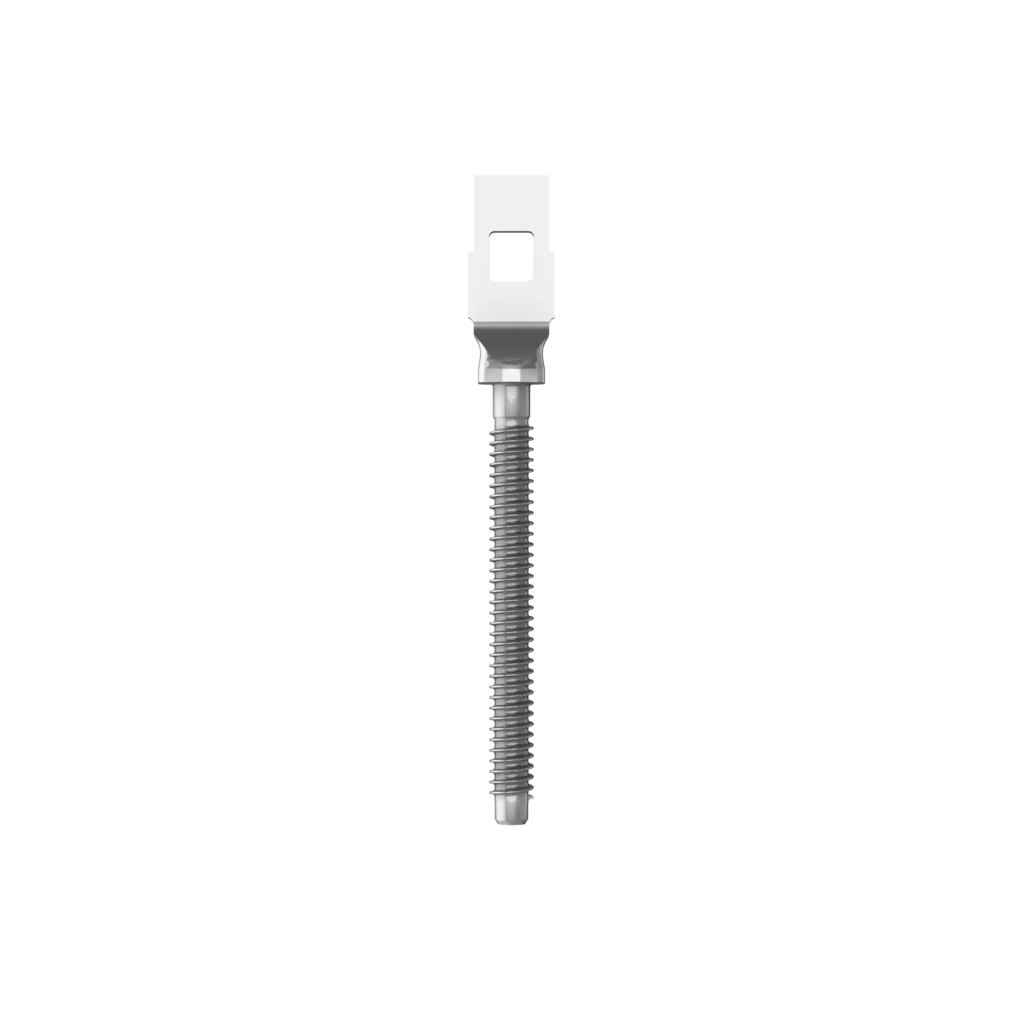

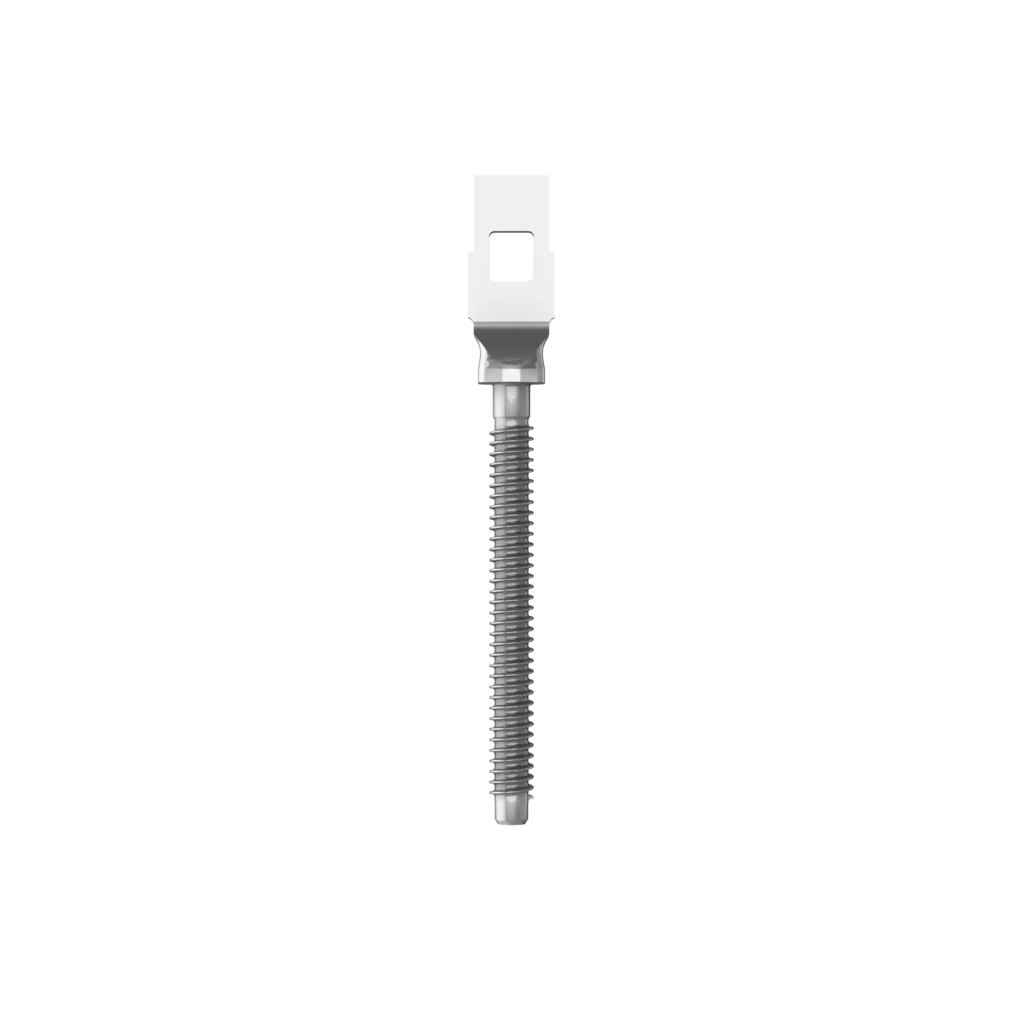

Lead Screws

Competencies

• Deformation of head on vertical press technology

• High cleanliness level required Zn coating

• Rolling of thread by dedicated machine with rollers

Main properties

• Low thread roughness

• Thread interfaced to the electric engine by plastic nut

• Handling and coating focused to reduce surface damages

• High fatigue performances

Applications

• Seats regulation

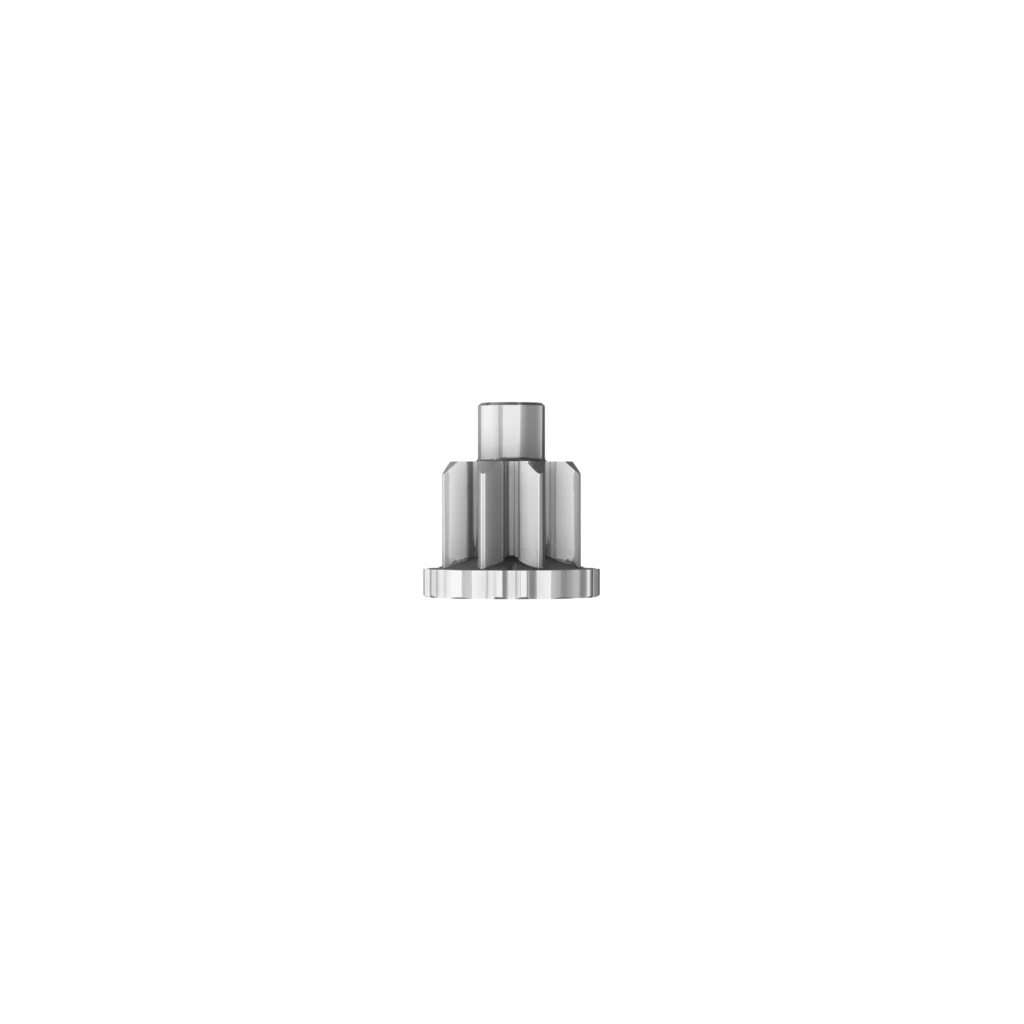

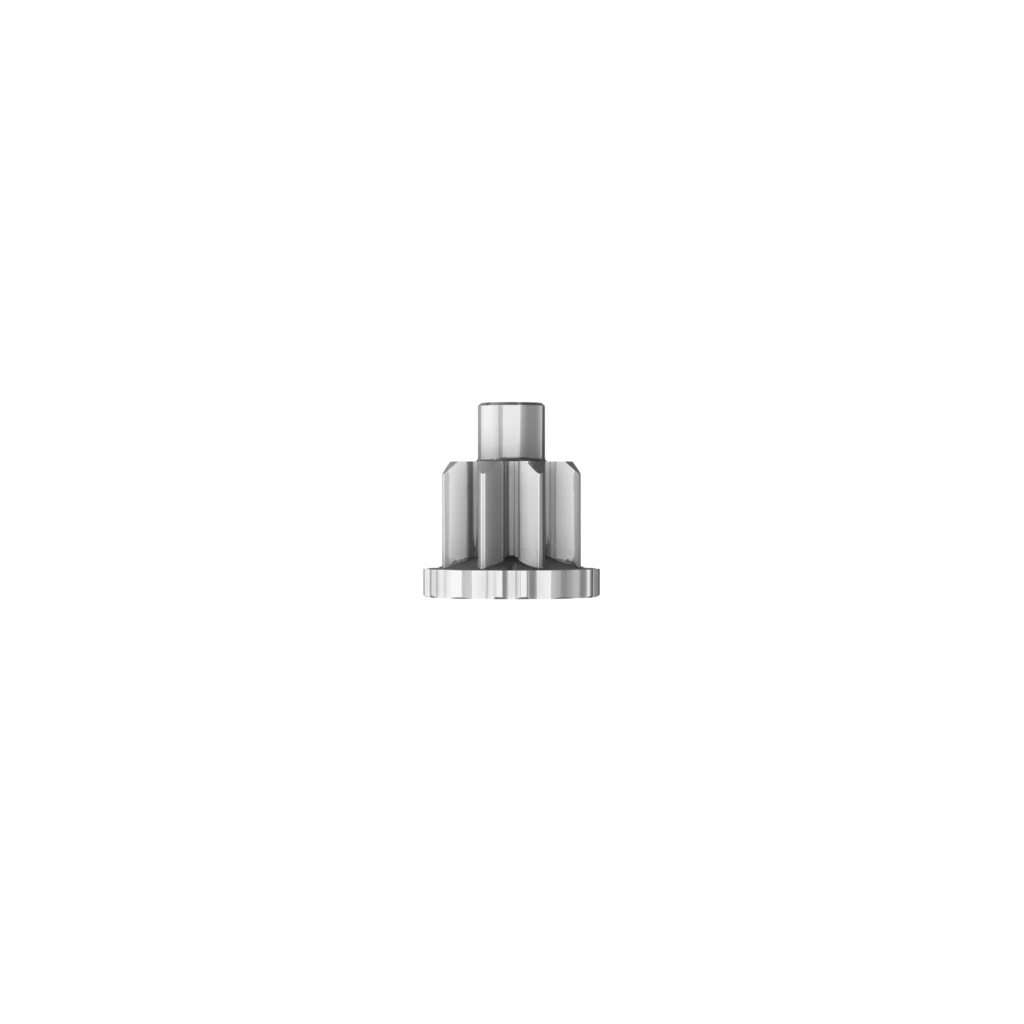

Pinion

Competencies

• Cold forged extruded shape

• High quality level and precision

• High mechanical properties

• High cleanliness and dedicated handling

• Dedicated machining

• Dedicated laser 100% sorting equipment

Main properties

• Gear quality class range 10-12

• Reference Pinion module 2.1and internal gear module 1.3

• Core hardness ∼ 350 HV10

• Surface hardness ∼ 700 HV10

• External cam profile fine blanked

• Internal gear profile extruded

• Absence of oxydation and shocks thanks to positioned H.T. in chamber furnace

• Overmoulded pinion

Applications

• Manual seat height adjuster

• Electric seat height adjuster

• Seats regulation

Engineered components used in several automotive applications

Shaft

Competencies

• Extrusion and fine blanking technology

• Secondary turning operation

• Small size forging machine with long kick out

• Centerless grinding

Main properties

• Slender part

• Corrosion resistance

• Small linearity and concentricity tolerances required

• complex shape

Applications

• Seats regulation

• Armrest regulation

Lead Screws

Competencies

• Deformation of head on vertical press technology

• High cleanliness level required Zn coating

• Rolling of thread by dedicated machine with rollers

Main properties

• Low thread roughness

• Thread interfaced to the electric engine by plastic nut

• Handling and coating focused to reduce surface damages

• High fatigue performances

Applications

• Seats regulation

Pinion

Competencies

• Cold forged extruded shape

• High quality level and precision

• High mechanical properties

• High cleanliness and dedicated handling

• Dedicated machining

• Dedicated laser 100% sorting equipment

Main properties

• Gear quality class range 10-12

• Reference Pinion module 2.1and internal gear module 1.3

• Core hardness ∼ 350 HV10

• Surface hardness ∼ 700 HV10

• External cam profile fine blanked

• Internal gear profile extruded

• Absence of oxydation and shocks thanks to positioned H.T. in chamber furnace

• Overmoulded pinion

Applications

• Manual seat height adjuster

• Electric seat height adjuster

• Seats regulation

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.