We offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements

Agrati produces over 5 million screws every day, primarily dedicated to the automotive market. In order to ensure high standards of quality, nearly all processes, such as tooling, wire drawing, cold forging, thread rolling, and heat treatments, are carried out internally or, in some specific cases, through qualified suppliers. This allows us to offer our OEM and Tier 1 customers the most innovative solutions and meet even their most specific requirements.

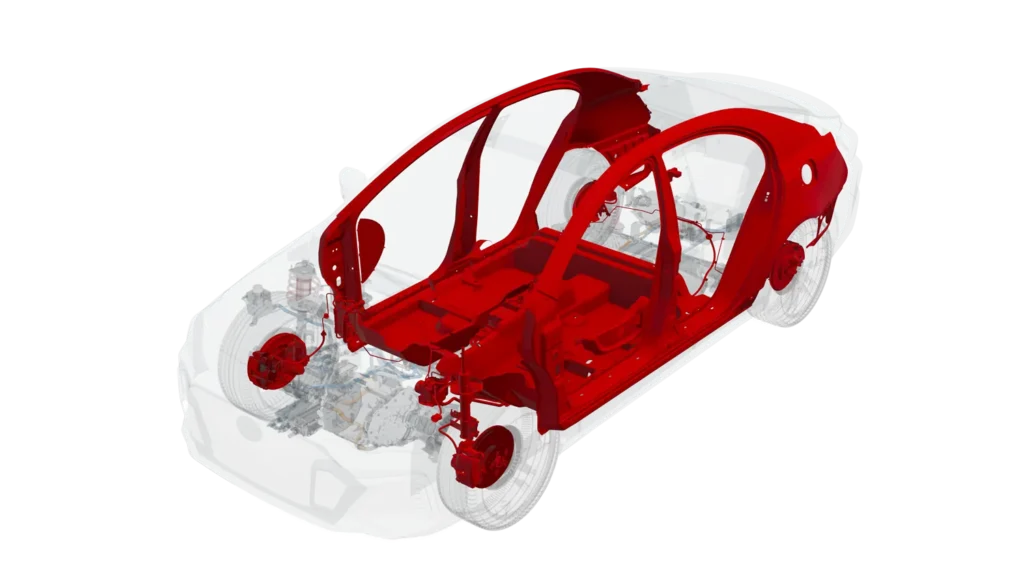

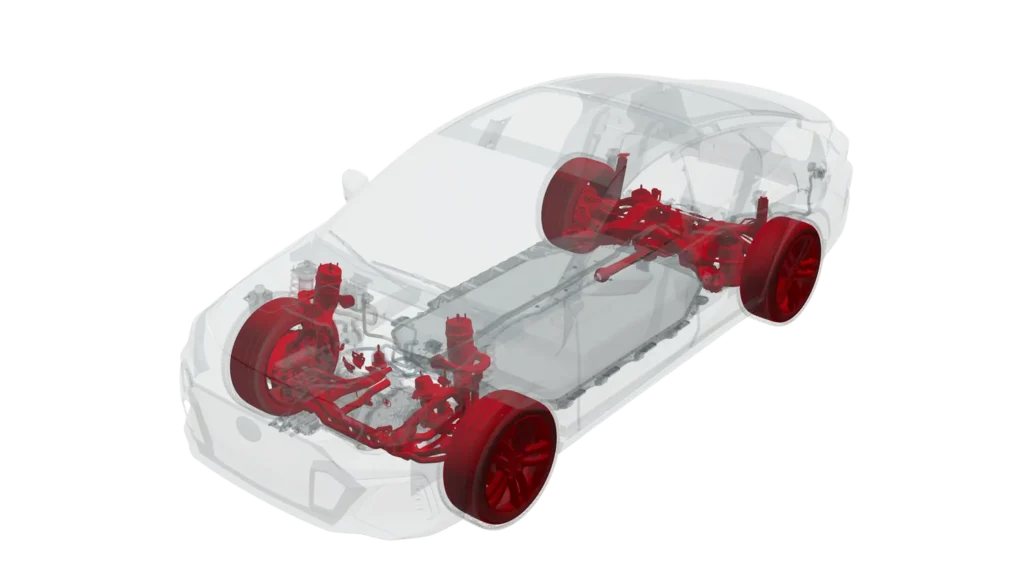

Engineered components used in several automotive applications

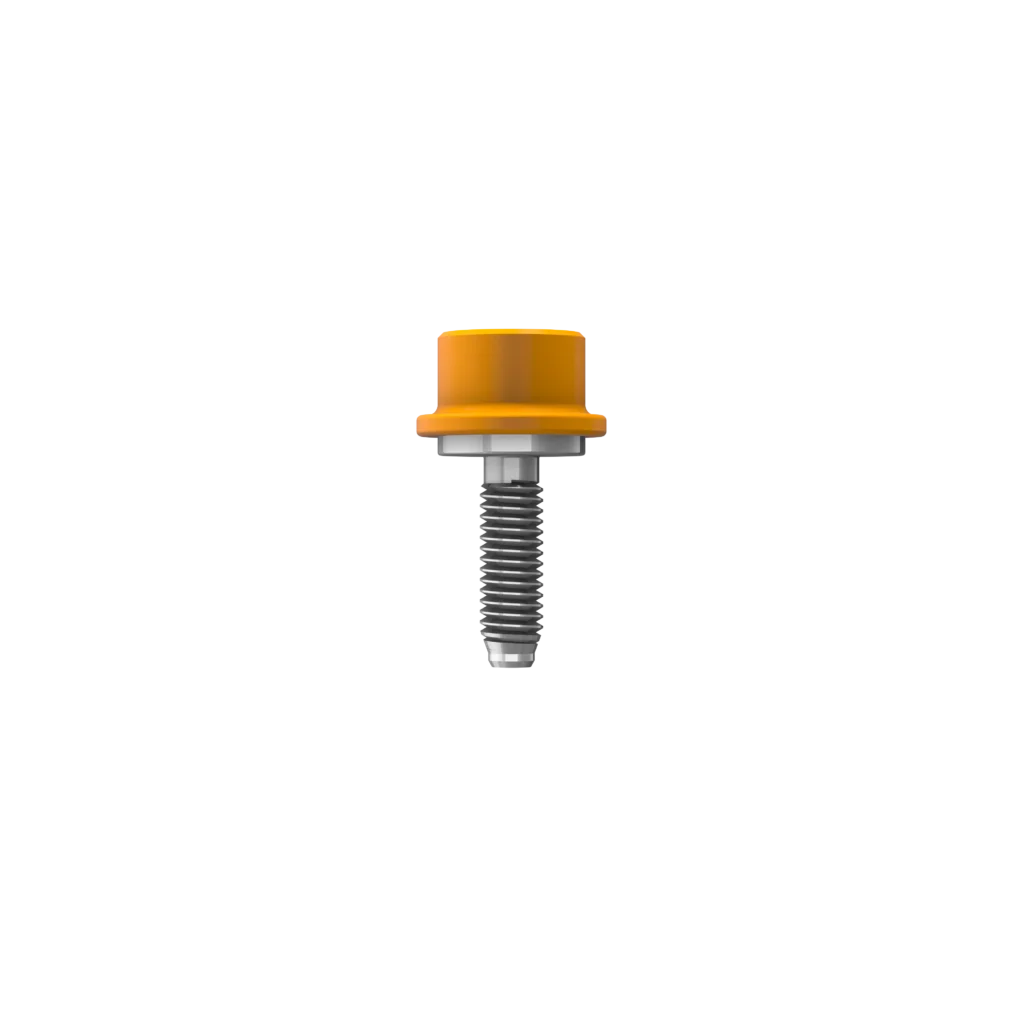

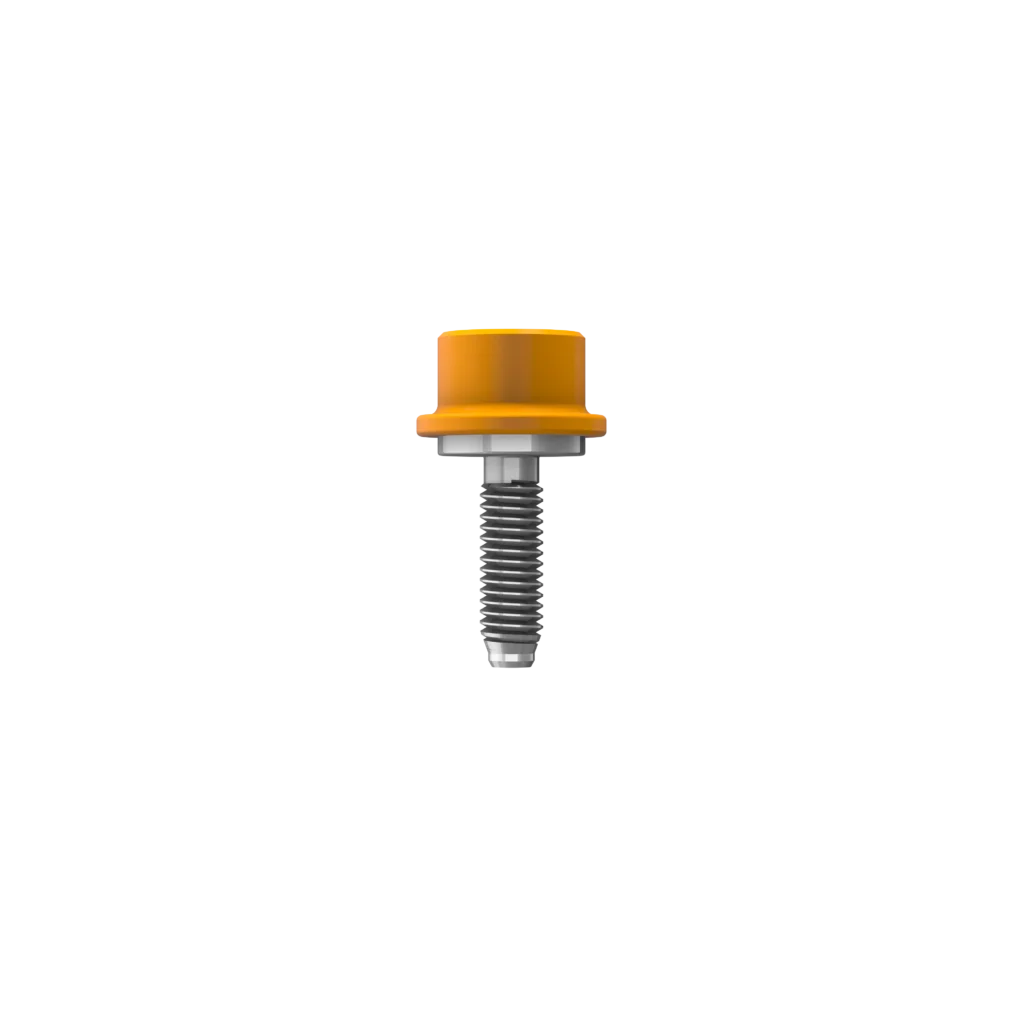

Touch-Safe Bolts

Main properties

• Thread size range: M3 to M6

• Property class: 8.8

• Touch-safe or Tool-safe functions can be designed

Competencies

• Fastener with electrical insulating properties

• Tailor made plastic materials can be formulated in view of specific requirements

• Part dimensions can be sized in view of customer needs

Applications

• Busbars fastening

• Power electronics

Bolt with Sealing Function

Main properties

• Sealing function in the threaded area

• Sealing function on the under-head surface

• Property class: 8.8 – 10.9

• Dimension: M6 – M16

Competencies

• Different sealing solutions can be provided on fastener elements

• O-rings

• Special sealing patches

• Vulcanized rubbers

Applications

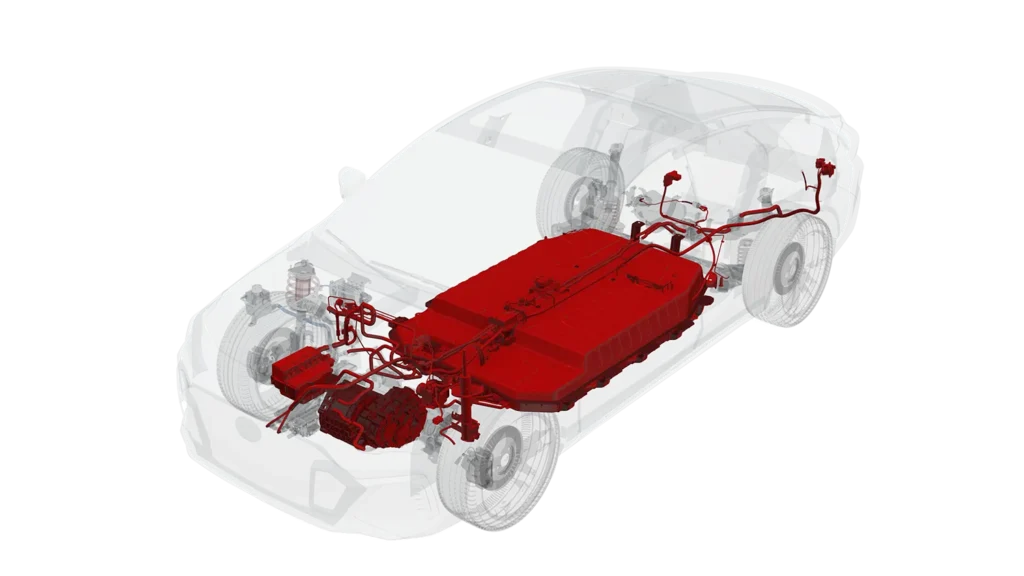

• Battery pack

• Power electronics

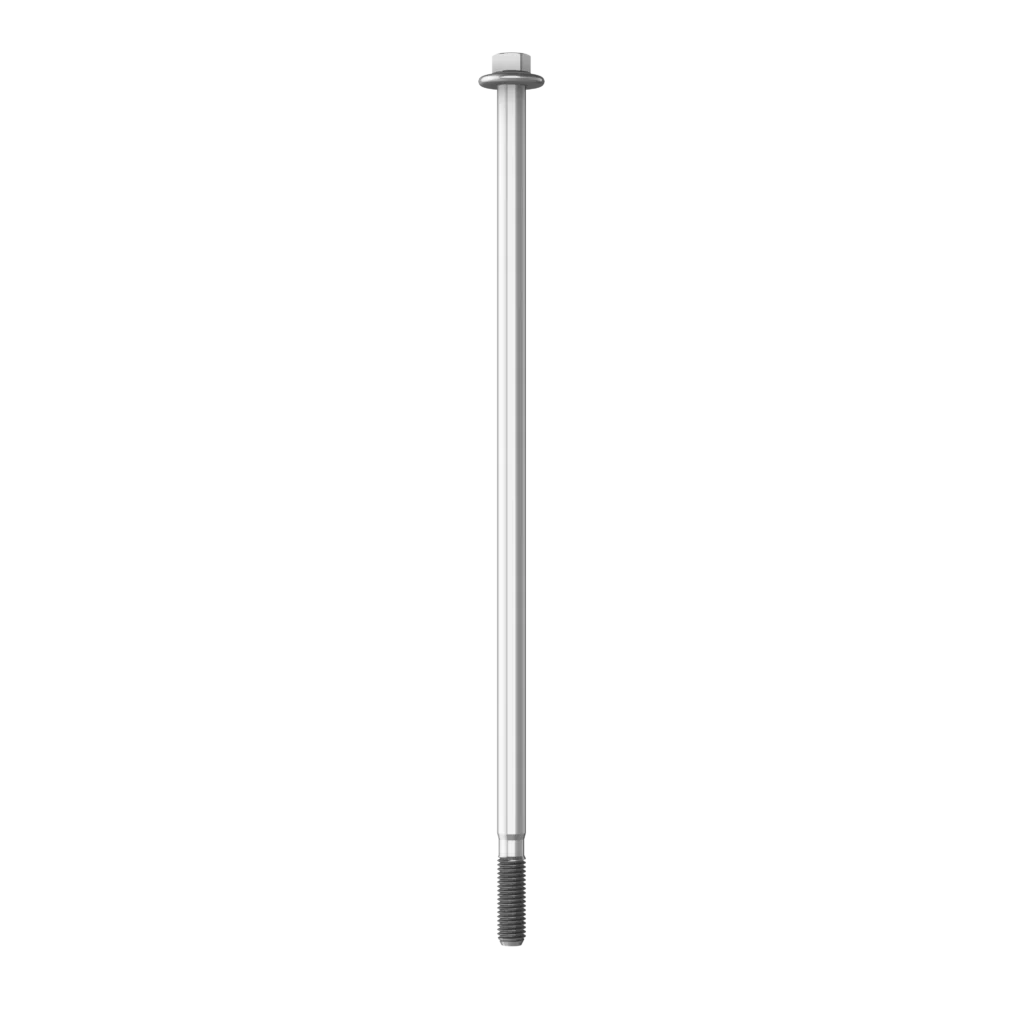

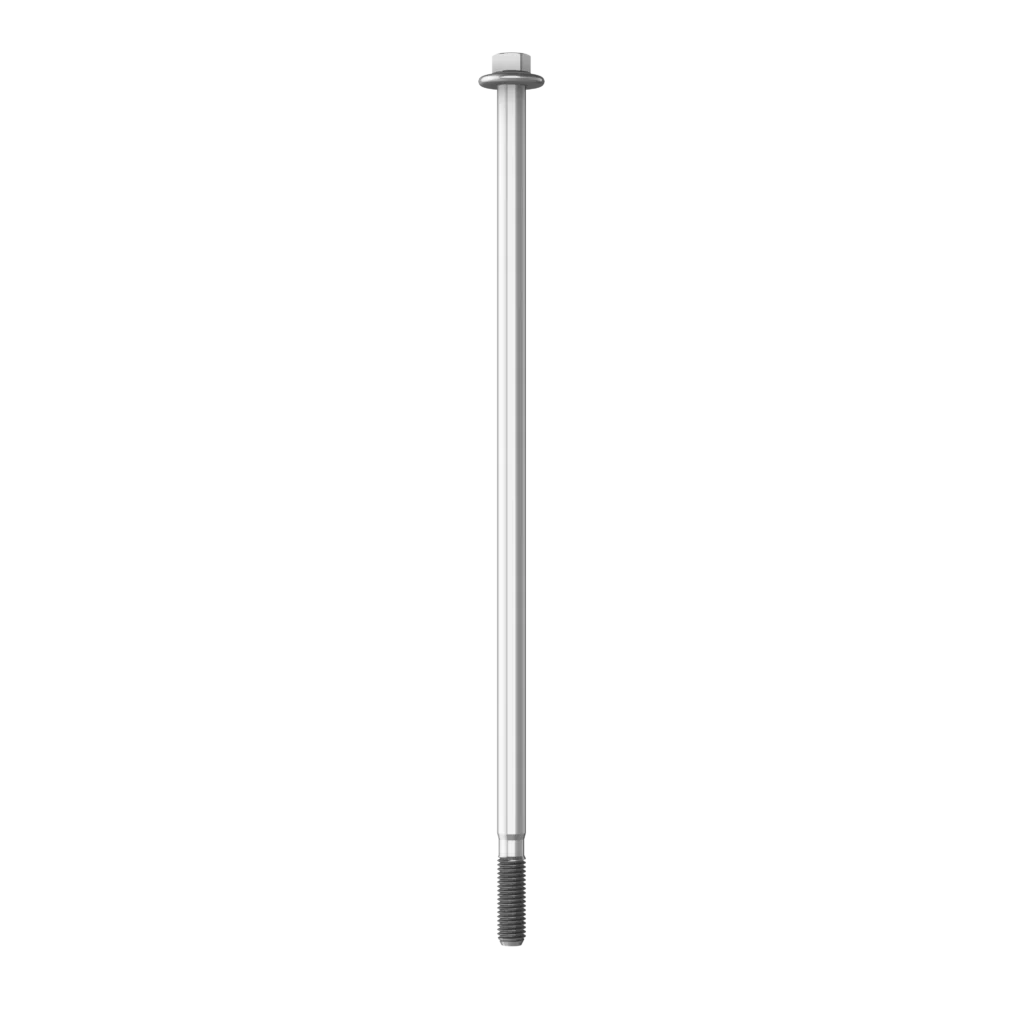

Long Bolt

Main properties

• Thread size range: M2 to M10

• Shank length range: special lengths up to 500 mm can be provided for thread sizes up to M6

• High cleanliness requirements can be managed

• Different thread diameters and thread positions

Competencies

• Wide range of products in terms of lengths, geometry and processes

• Special cold forging machine to produce long bolts

Applications

• Battery pack / modules

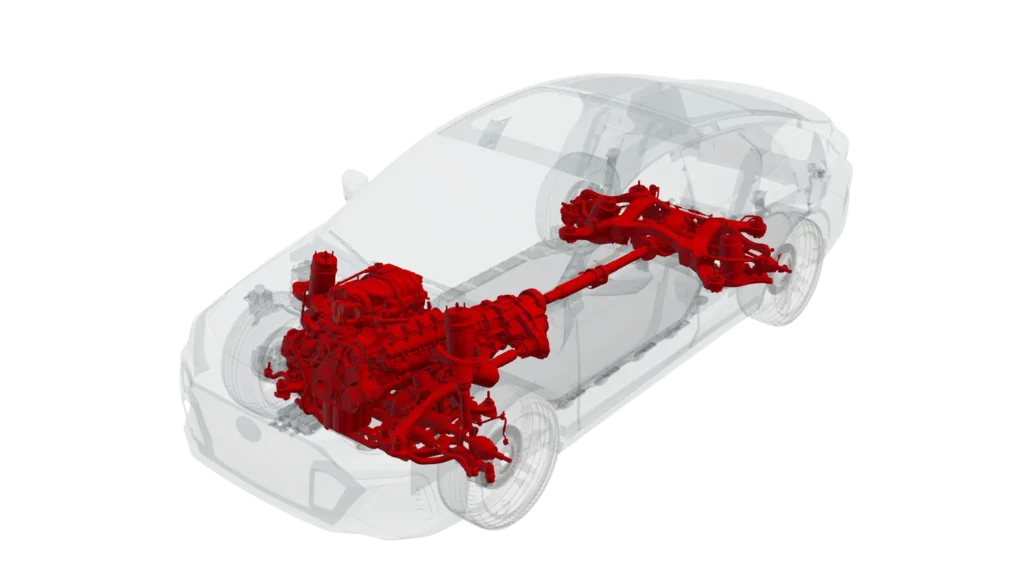

• Electric motor rotor/stator bolts

• Power tubes (e-bikes batteries)

Engineered components used in several automotive applications

Touch-Safe Bolts

Main properties

• Thread size range: M3 to M6

• Property class: 8.8

• Touch-safe or Tool-safe functions can be designed

Competencies

• Fastener with electrical insulating properties

• Tailor made plastic materials can be formulated in view of specific requirements

• Part dimensions can be sized in view of customer needs

Applications

• Busbars fastening

• Power electronics

Bolt with Sealing Function

Main properties

• Sealing function in the threaded area

• Sealing function on the under-head surface

• Property class: 8.8 – 10.9

• Dimension: M6 – M16

Competencies

• Different sealing solutions can be provided on fastener elements

• O-rings

• Special sealing patches

• Vulcanized rubbers

Applications

• Battery pack

• Power electronics

Long Bolt

Main properties

• Thread size range: M2 to M10

• Shank length range: special lengths up to 500 mm can be provided for thread sizes up to M6

• High cleanliness requirements can be managed

• Different thread diameters and thread positions

Competencies

• Wide range of products in terms of lengths, geometry and processes

• Special cold forging machine to produce long bolts

Applications

• Battery pack / modules

• Electric motor rotor/stator bolts

• Power tubes (e-bikes batteries)

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.