We develop the best solution tailored to the customers needs, either independently or based on the provided customer design

Over time, Agrati has also specialized in the production of nuts.

Nearly 2 million nuts are produced each month, and over the years, all stages of the process have been perfected, from design to shipment, in order to ensure increasingly high standards of quality and safety, resulting in zero defects in the product.

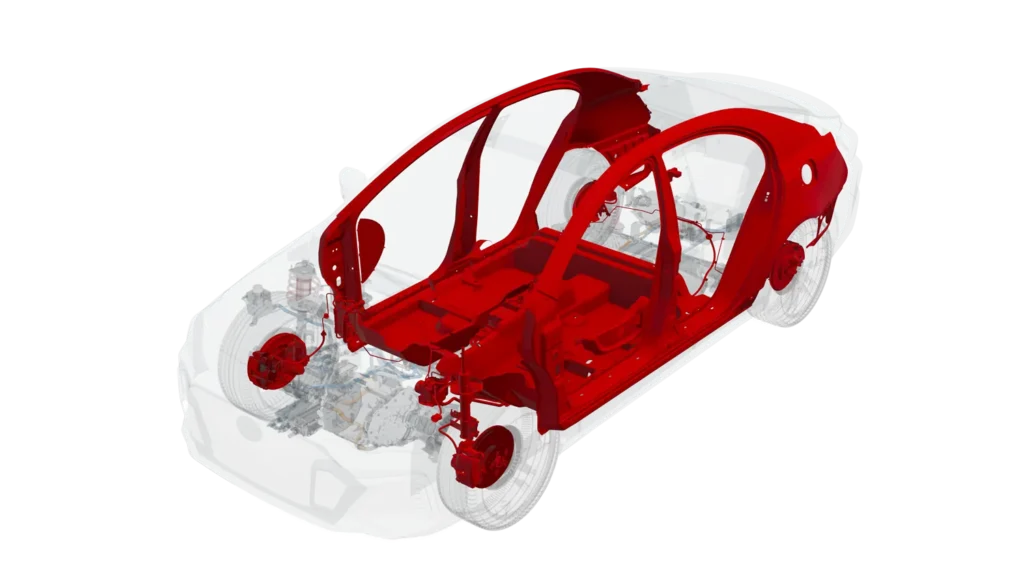

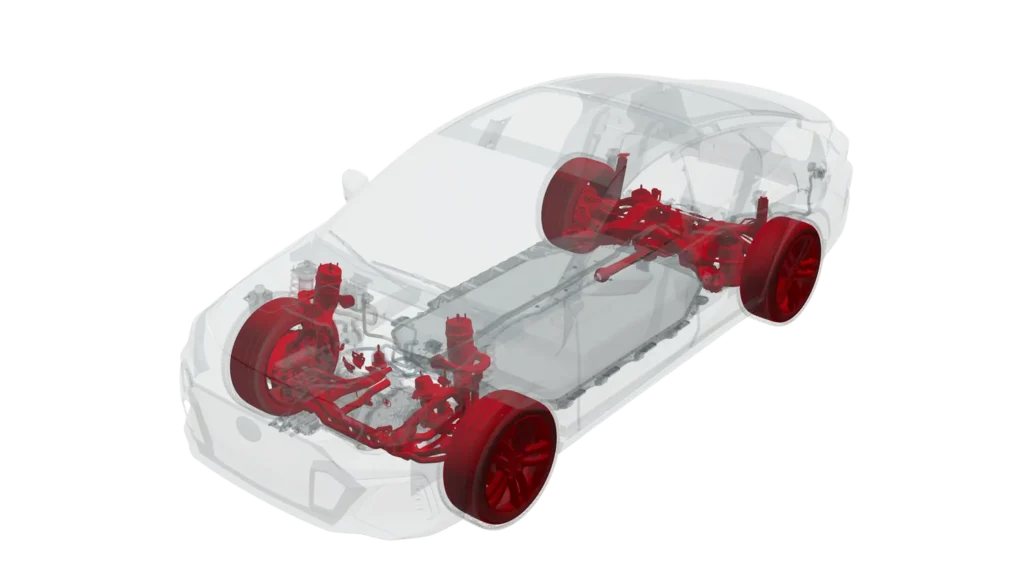

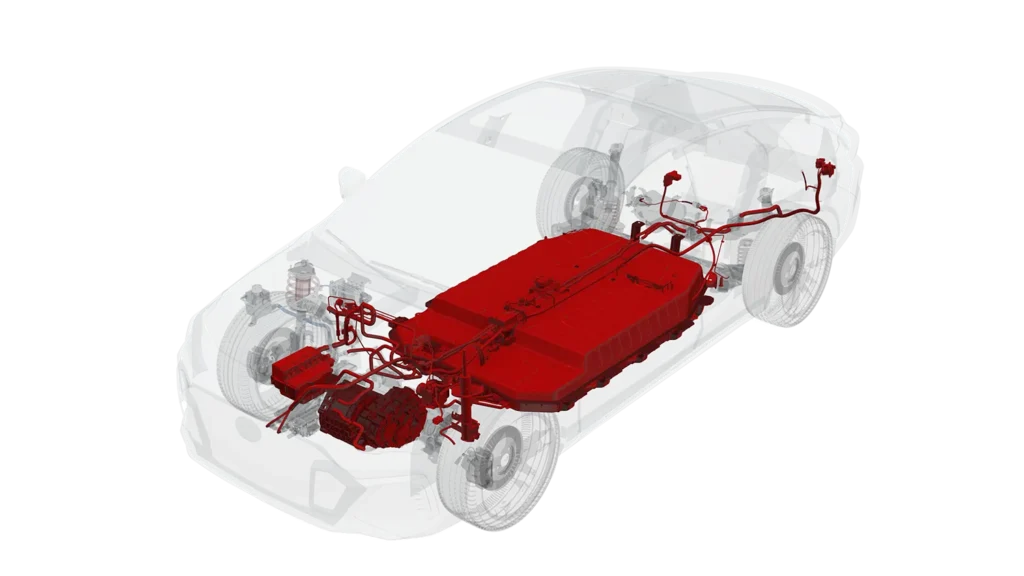

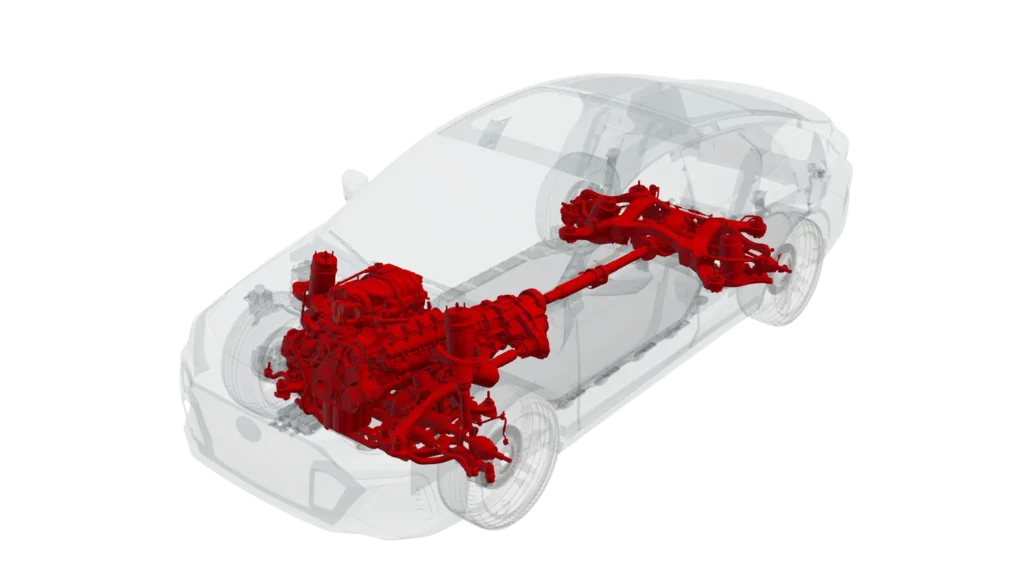

Engineered components used in several automotive applications

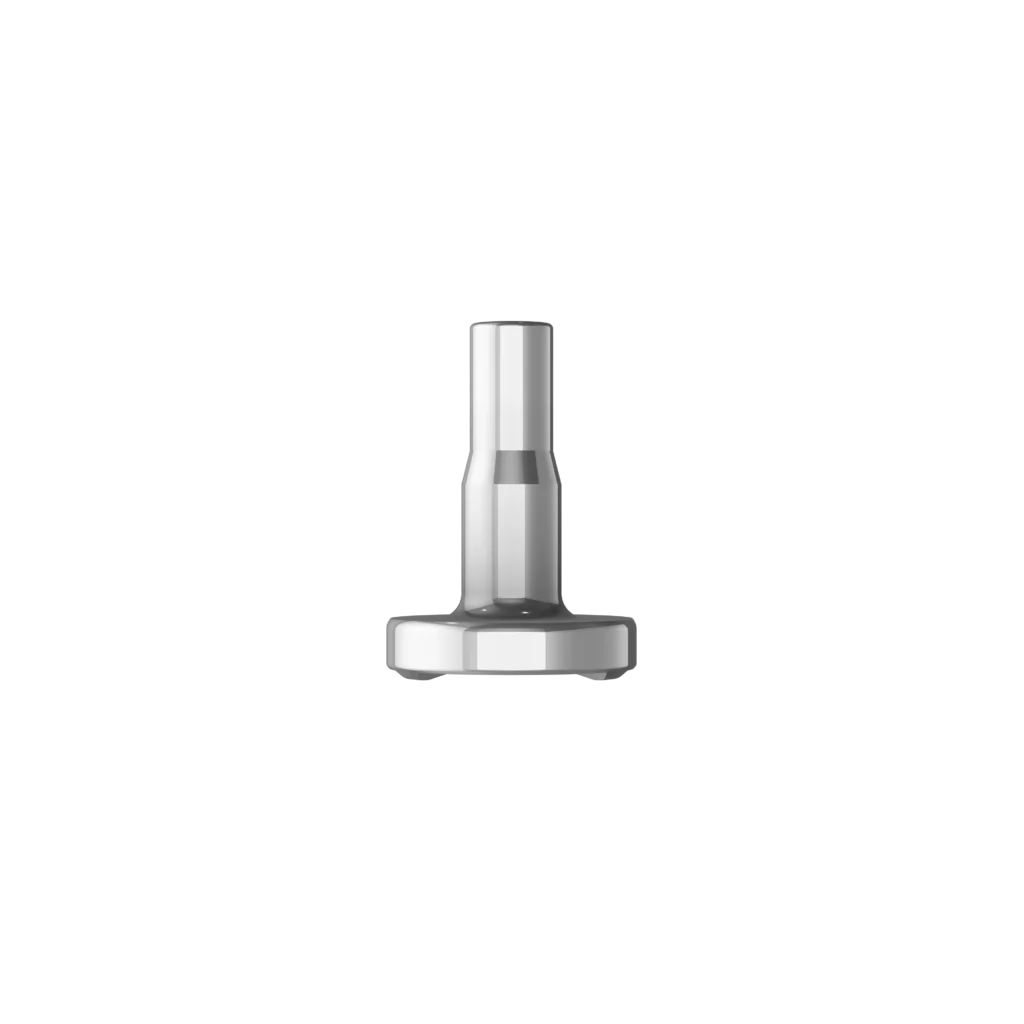

Pipe Nut

Competencies

• Suitable materials for the welding process.

• Agrati optimized design is made by assembled metal sheet and special nut: nut with property class 8 or 10, metal sheet suitable for welding operations.

Main properties

•Size: M12-M16

• Property class 8-10

Applications

• Nuts for sheet metal components

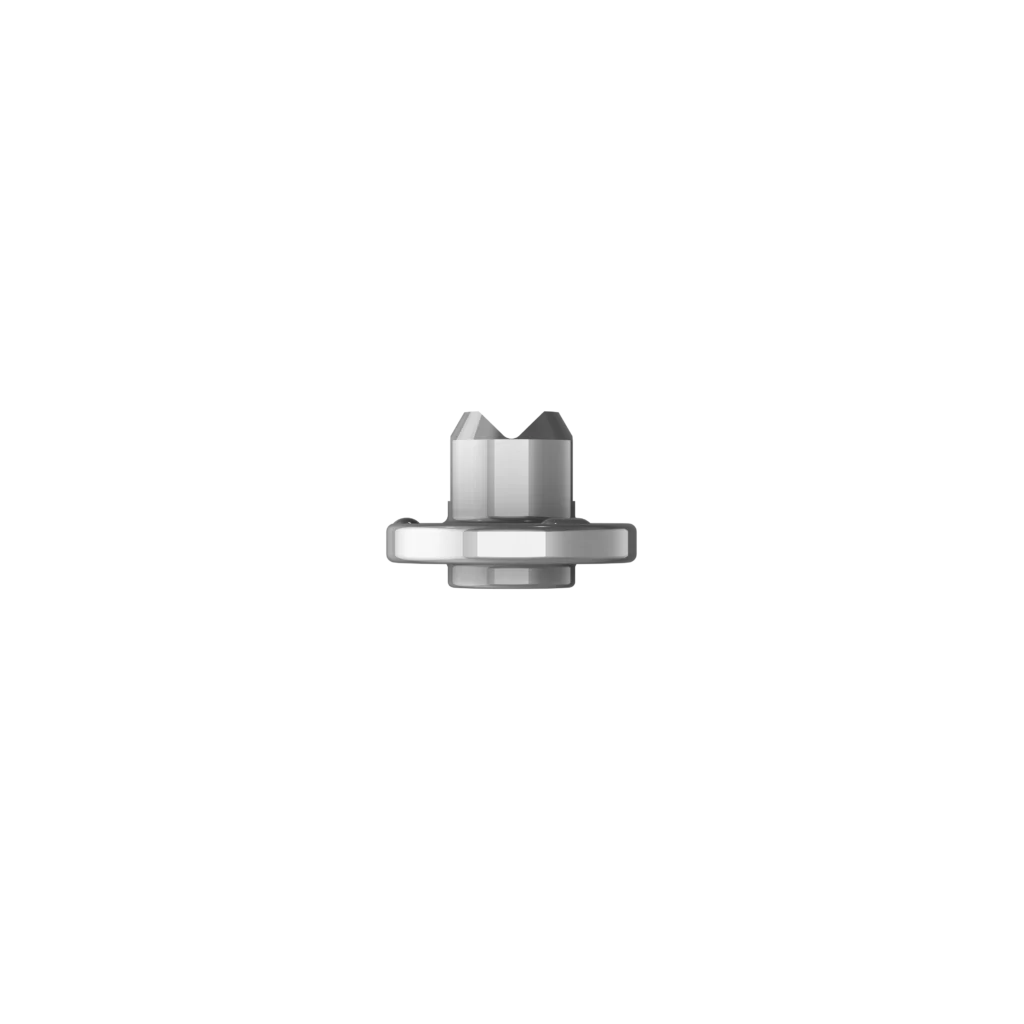

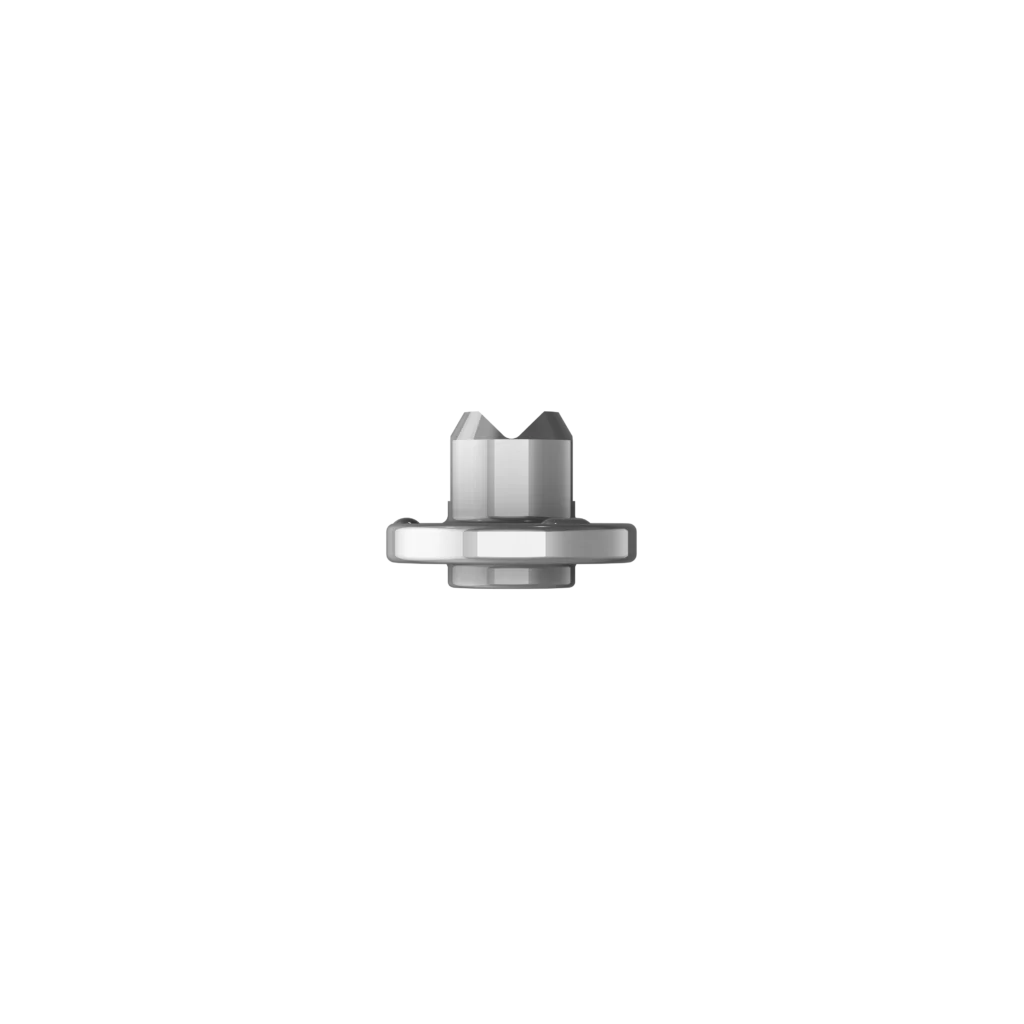

Weld Nut

Competencies

• Standard nut design or special geometries can be provided

• Suitable materials for the welding process.

• Different surface finishes can be provided, depending on requirements

• Thread mask can be provided

Main properties

• Size: M5 – M16

• Proof load till class 12 with proper geometry

Applications

• Nuts for sheet metal components

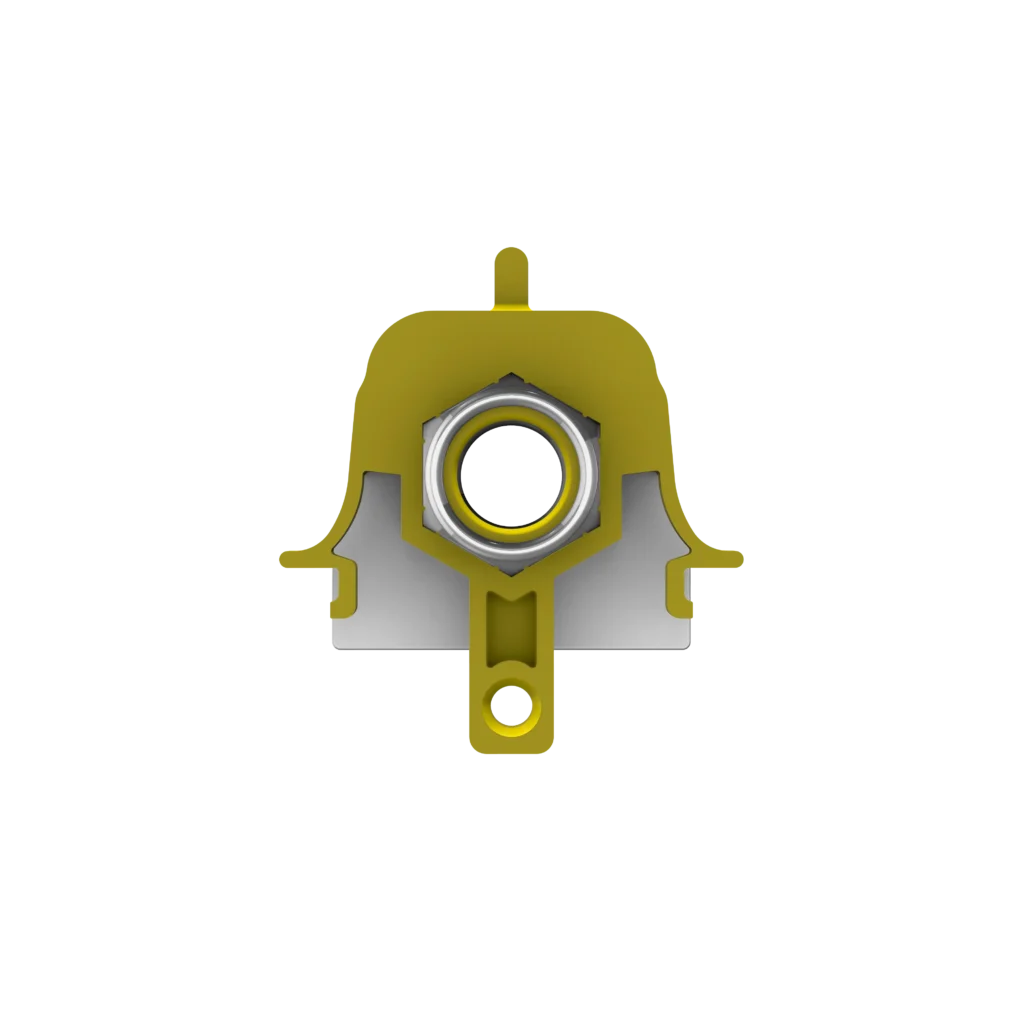

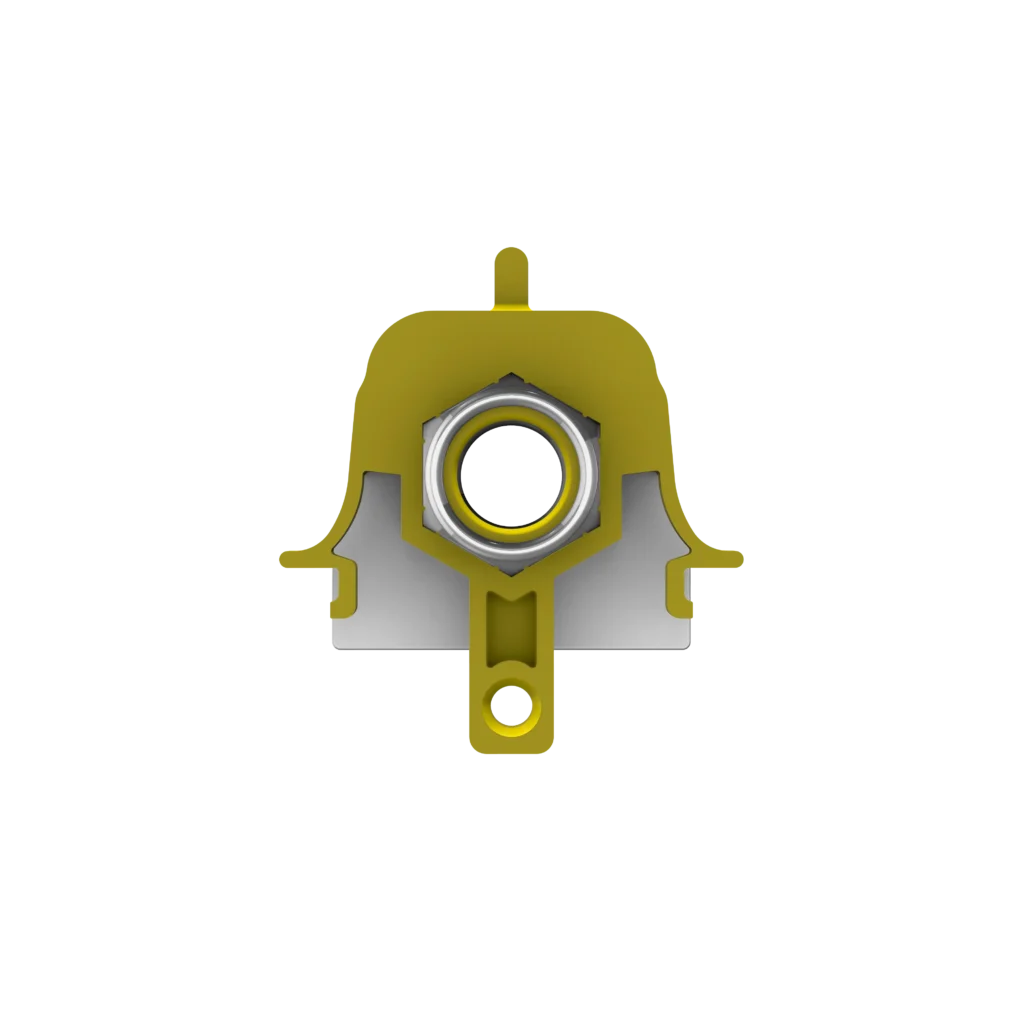

Cage Nut

Competencies

• Metal cage or hybrid solutions with metal – plastic materials are available

• Customized configurations can be designed

• Prevailing torque properties can be provided

Main properties

• Size: M12 – M14

• Property class 8-12

• Clearance recovery capabilities can be customized

• Reduction of non-quality costs related to tightening processes in assembly lines

Applications

• Nuts for sheet metal components

Engineered components used in several automotive applications

Pipe Nut

Competencies

• Suitable materials for the welding process.

• Agrati optimized design is made by assembled metal sheet and special nut: nut with property class 8 or 10, metal sheet suitable for welding operations.

Main properties

•Size: M12-M16

• Property class 8-10

Applications

• Nuts for sheet metal components

Weld Nut

Competencies

• Standard nut design or special geometries can be provided

• Suitable materials for the welding process.

• Different surface finishes can be provided, depending on requirements

• Thread mask can be provided

Main properties

• Size: M5 – M16

• Proof load till class 12 with proper geometry

Applications

• Nuts for sheet metal components

Cage Nut

Competencies

• Metal cage or hybrid solutions with metal – plastic materials are available

• Customized configurations can be designed

• Prevailing torque properties can be provided

Main properties

• Size: M12 – M14

• Property class 8-12

• Clearance recovery capabilities can be customized

• Reduction of non-quality costs related to tightening processes in assembly lines

Applications

• Nuts for sheet metal components

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.