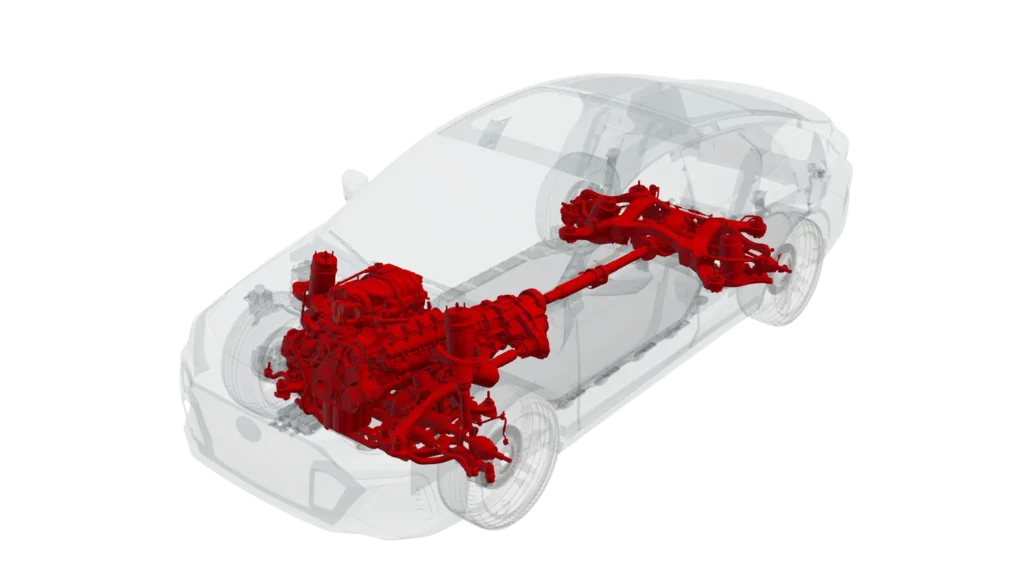

Advanced Form Parts are engineered components that can be manufactured with the core Agrati Group technology: the cold forging process.

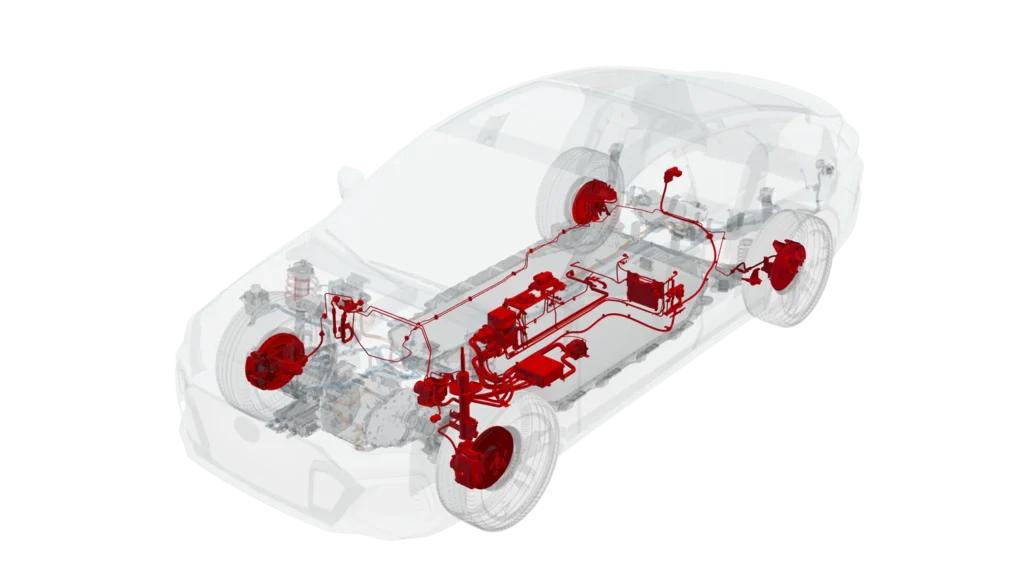

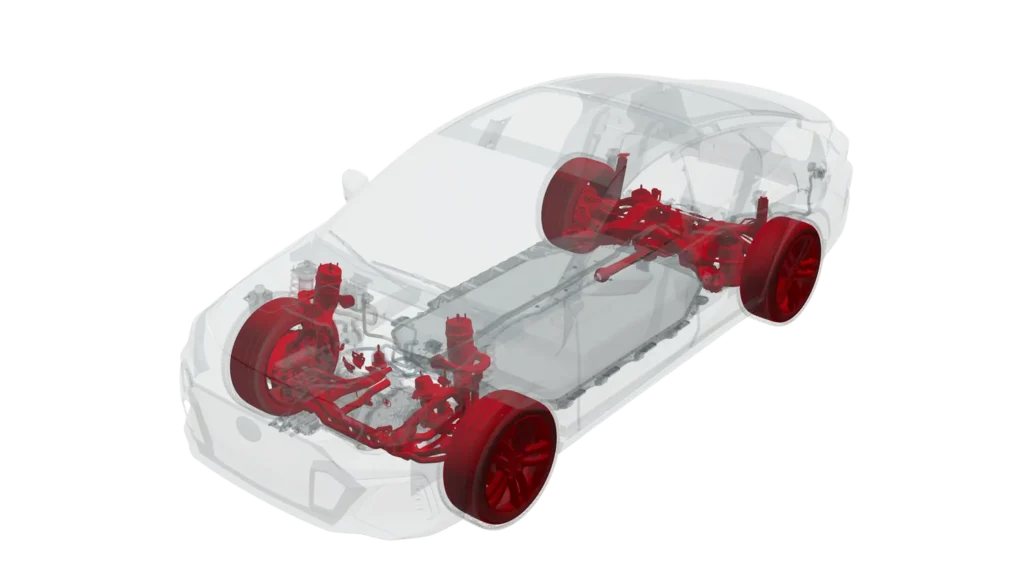

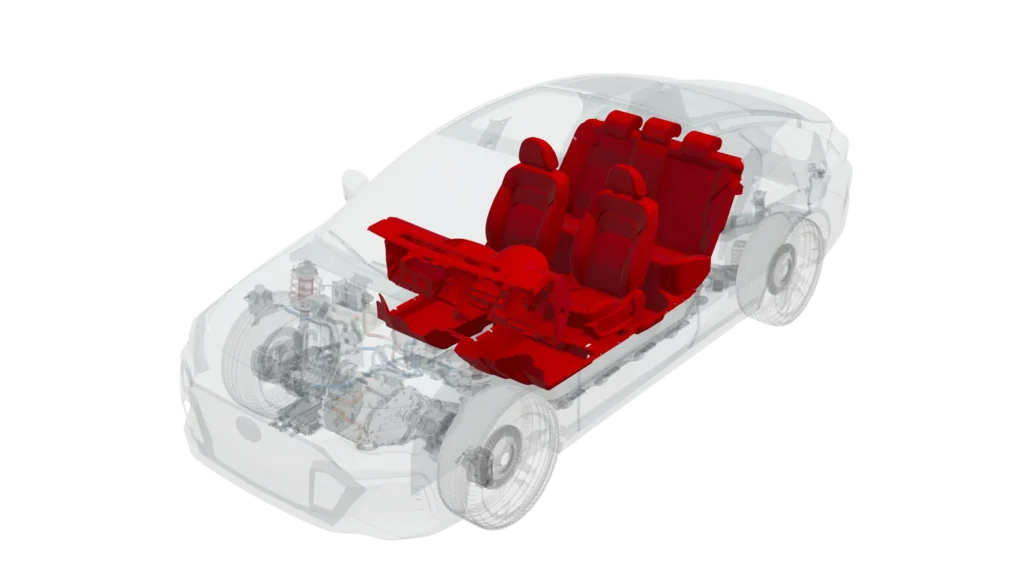

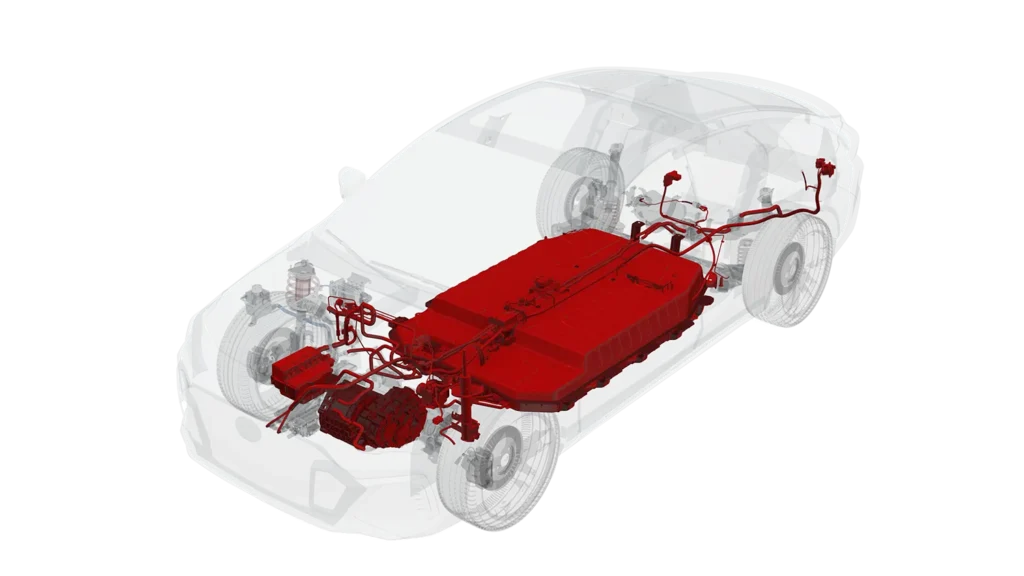

These parts are used in several fields of automotive applications:

- chassis

- seatings

- brakes and safety systems

- engine

- powertrain & driveline systems

These are products manufactured according to strict customer specifications.

Dedicated control plans during production and the ability to do 100% sorting before packaging guarantee the complete fulfilment of quality requirements.

Engineered components used in several automotive applications

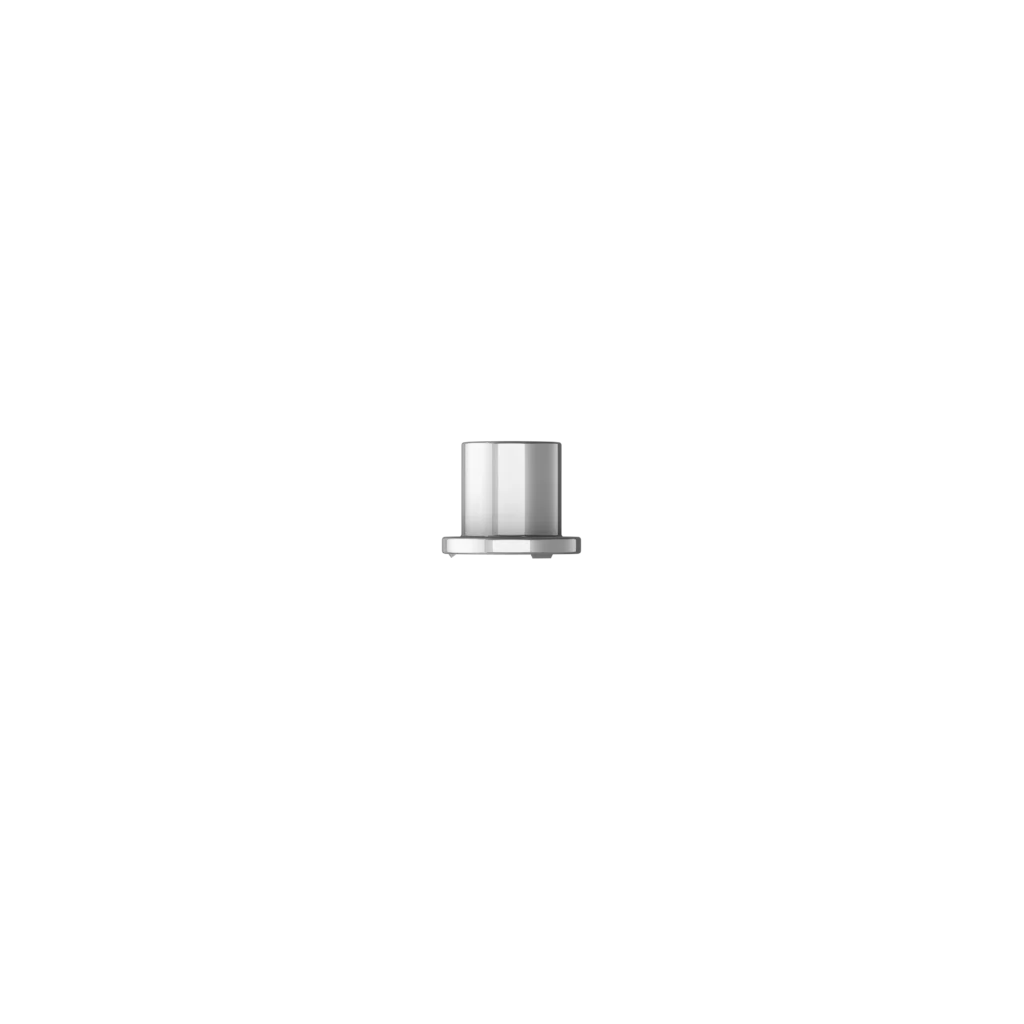

Welded Bushing

Competencies

• Complex geometries with projections realized by forging

• Geometry design suitable for welding process

• Great versatility for light weight approach

• Inner thread rolled or machined

Main properties

• Max diameter up to 50 mm

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to heat treat parts separately

• Weldability

• Surface finishing: blank or coating where needed

Applications

• Function as mother-thread

• Avoid heavy chassis structures

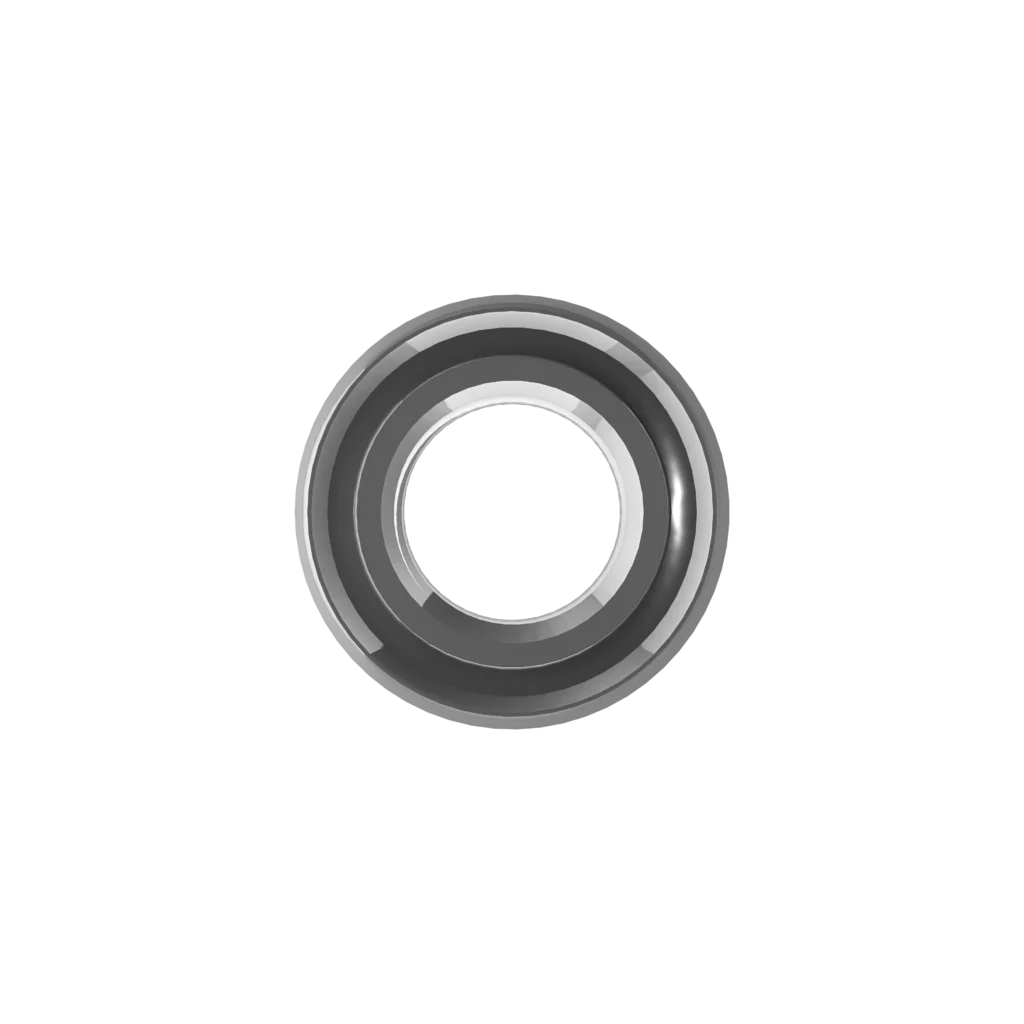

Chain Rollers

Competencies

• Need of medium-big forging machines

• Washing and rust protection required

Main properties

• Typical forging material

• Quench and tempered to high hardness values

• Tight tolerance on ID and OD

Applications

• Industrial chains of medium or big size vehicles or systems

Tank Fittings

Competencies

• Extreme forging cycle

• Part with shape suitable for welding on counterpart

• Threading of inner tapered thread

Main properties

• Very thin and large part

• High quality required due to assembly welding procedure

Applications

• Propane vessel

• Heating system

• Cooling system

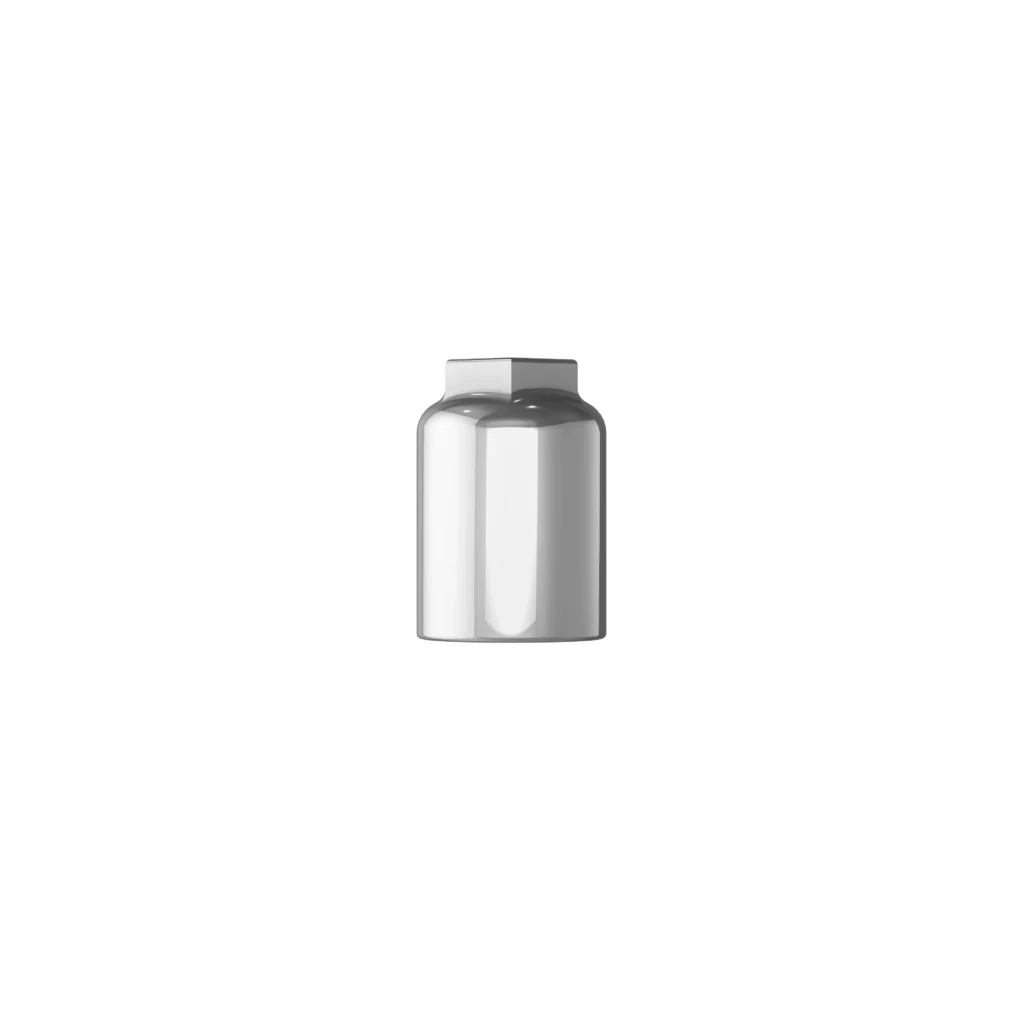

Hose Fittings Blank

Competencies

• Forging on big size machine

• Complex forging cycle to achieve the required shape

• Rolling of marking

Main properties

• Blank to be fully machined on the ID to make hose coupling thread

• Marking to identify the product type by customer

Applications

• Hose fittings

Engineered components used in several automotive applications

Welded Bushing

Competencies

• Complex geometries with projections realized by forging

• Geometry design suitable for welding process

• Great versatility for light weight approach

• Inner thread rolled or machined

Main properties

• Max diameter up to 50 mm

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to heat treat parts separately

• Weldability

• Surface finishing: blank or coating where needed

Applications

• Function as mother-thread

• Avoid heavy chassis structures

Chain Rollers

Competencies

• Need of medium-big forging machines

• Washing and rust protection required

Main properties

• Typical forging material

• Quench and tempered to high hardness values

• Tight tolerance on ID and OD

Applications

• Industrial chains of medium or big size vehicles or systems

Tank Fittings

Competencies

• Extreme forging cycle

• Part with shape suitable for welding on counterpart

• Threading of inner tapered thread

Main properties

• Very thin and large part

• High quality required due to assembly welding procedure

Applications

• Propane vessel

• Heating system

• Cooling system

Hose Fittings Blank

Competencies

• Forging on big size machine

• Complex forging cycle to achieve the required shape

• Rolling of marking

Main properties

• Blank to be fully machined on the ID to make hose coupling thread

• Marking to identify the product type by customer

Applications

• Hose fittings

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.