Our mission in Action

At Agrati Tech Center, our mission to be a dynamic, reliable, and expert innovation partner takes shape through four key activities that guide every project we develop:

Co-Design

Prototypes

Testing & Validation

Impact Innovation

These pillars define our approach and ensure that every solution developed at ATC is robust, innovative, and ready for the future.

Deep-dive on our technical Competencies

Deep knowledge of materials, heat treatments and failure mechanisms to support innovation, lightweighting and sustainability goals

Proprietary and customer-specified coatings. Process validation and performance optimization

Coating Technical Datasheet

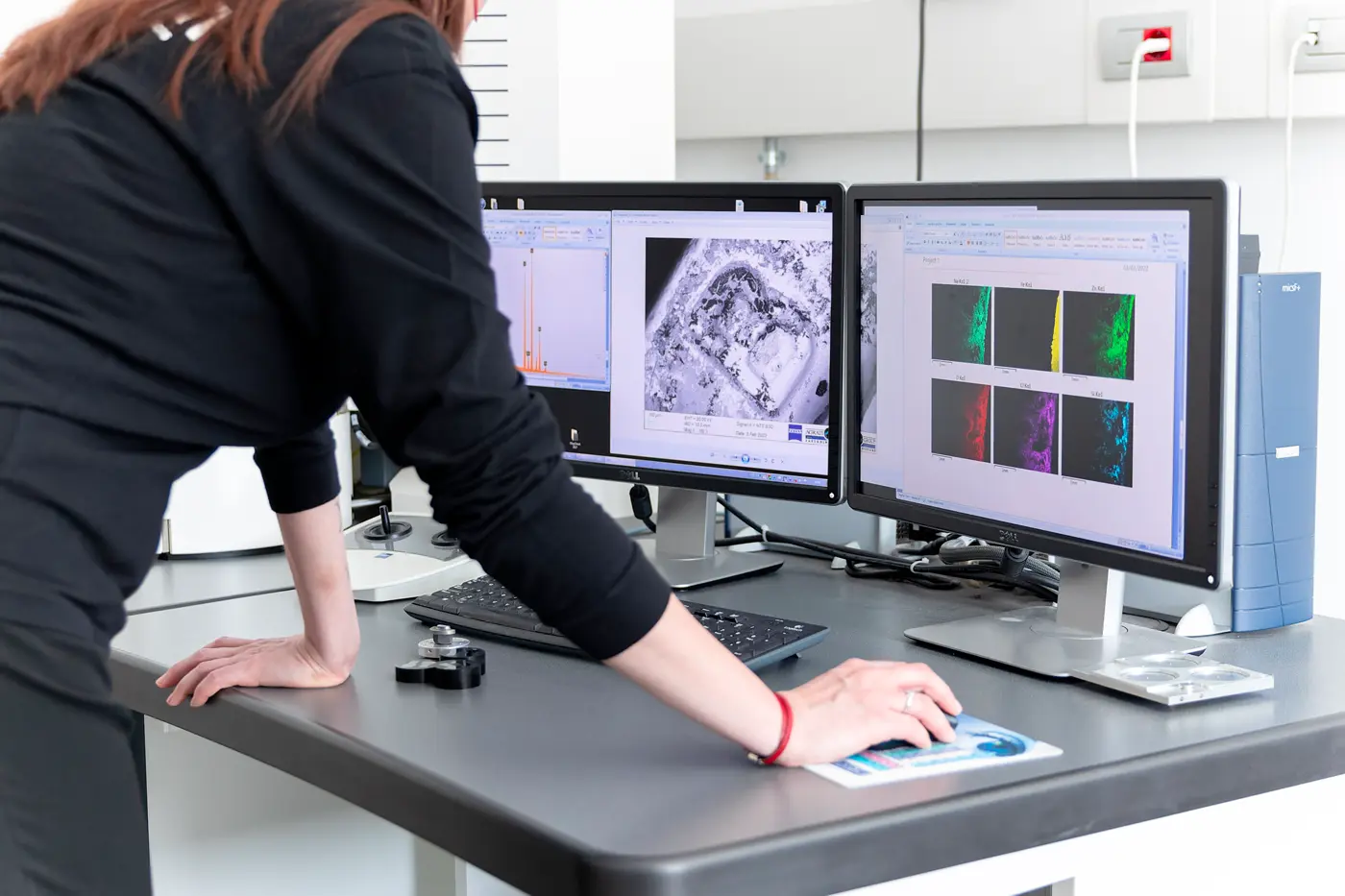

Comprehensive testing to ensure that fastening solutions perform reliably under real application conditions

One critical aspect that directly impacts both performance and safety in high-voltage applications is the conductivity of bolted joints.

Recognizing this need and the gap in international standards, our commitment is to provide customers with the most cost-effective solutions. Additionally, we offer conductivity trials tailored to meet specific customer requirements.

What?

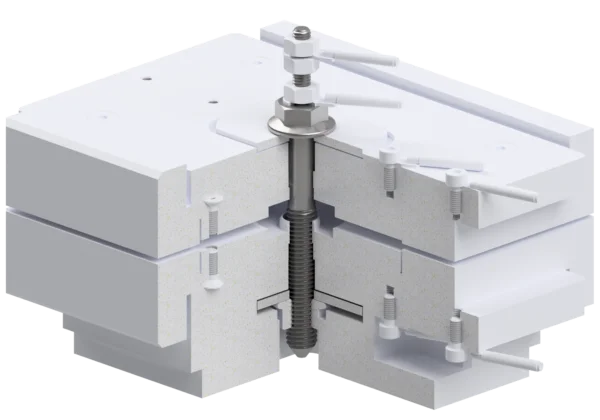

An innovative test setup developed to compare various coating systems and joint materials.

Aimed at ensuring optimal performance while minimizing costs, this setup promises to standardize conductivity measurements.

Why?

With the electric vehicle (EV) industry rapidly advancing, the need for reliable bolted joint conductivity is essential.

Our setup addresses this need, ensuring that performance and cost-effectiveness are not compromised in the face of increasing demand.

Where?

This setup represents a collective effort towards customer requirements and deep knowledge.

With a focus on enhancing conductivity in bolted joints, it sets a new standard in the EV market, promising controlled performance at a lower cost.

Our team is dedicated to addressing the challenges posed by the growing EV market

Strong points:

- Portable setup

- Kelvin method (4 points) approach for precise measurements

- Multiple contact resistance measurements

- Inspection of conductivity versus clamping force

- Capability to change counterpart material to simulate real applications

Fastener and joint engineering supported by FEA, preload analysis, and design optimization for cost and performance

Agile production of small and medium batches for rapid testing, proof of concept and early-stage validation