We guarantee safe,

durable and tailor-made solutions

Explore more

Customer Journey

What we offer

The ultimate customization and security solution

Competencies

• Agrati patent for the safety system

• In -ouse development engineering for new Monolock

• Responsible for validation test management for new Monolock development

Advantages & Properties:

• Customizable key geometry

• Customizable cover geometry

• Responsible for validation test management for new Monolock development

• Possibility to paint the cover + apply markings/text

• Safety system integrated in the Monolock (quick release mechanism)

• Dedicated Tool to apply the correct torque

• Raw material: aluminum; steel; titanium

Applications

• Wheels (center lock)

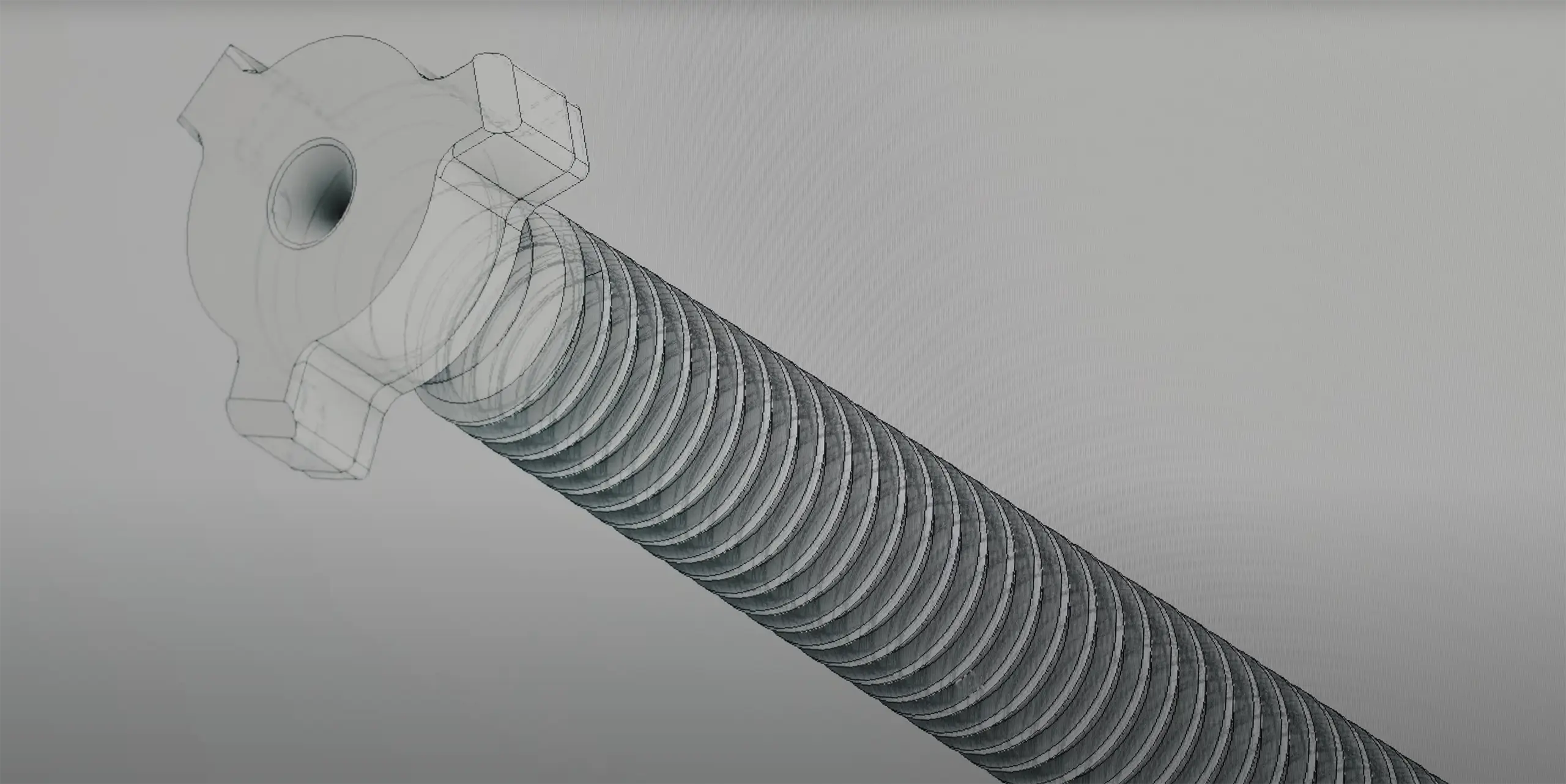

Advanced coating solutions for enhanced multi-tightening performance

Competencies

• Special coating developed by Agrati Performance for multi-tightening

• Engineering development of special geometries

Advantages & Properties:

• The coefficient of friction remains complaint within the specified range (6 points) throughout 5 tightening cycles

• Weight reduction compared to standard steel solution

Applications

• Wheels (Bolts / Nuts)

• Battery packs (cover)

• Body area

• Chassis area

• Interiors area