Advanced Form Parts are engineered components that can be manufactured with the core Agrati Group technology: the cold forging process.

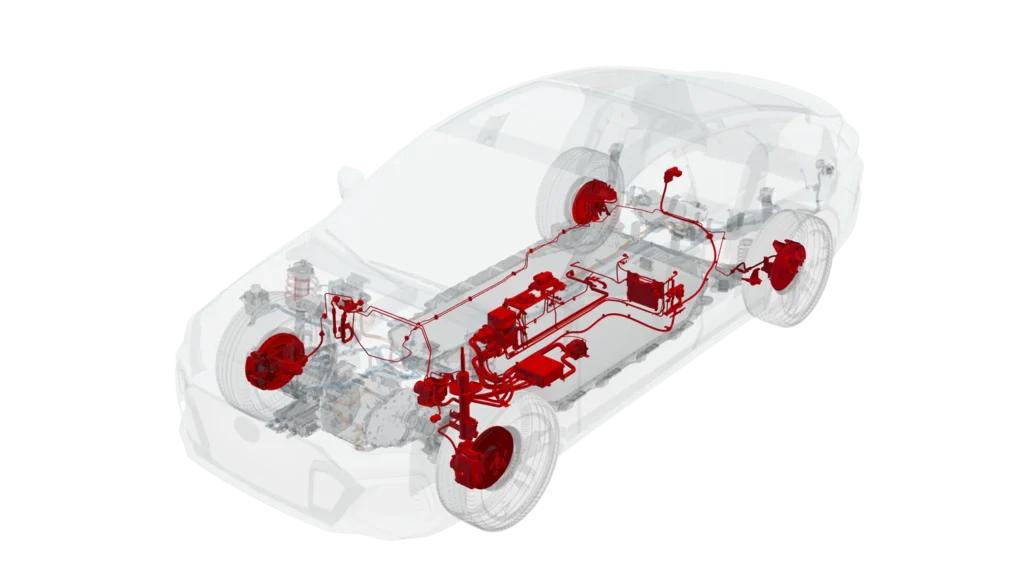

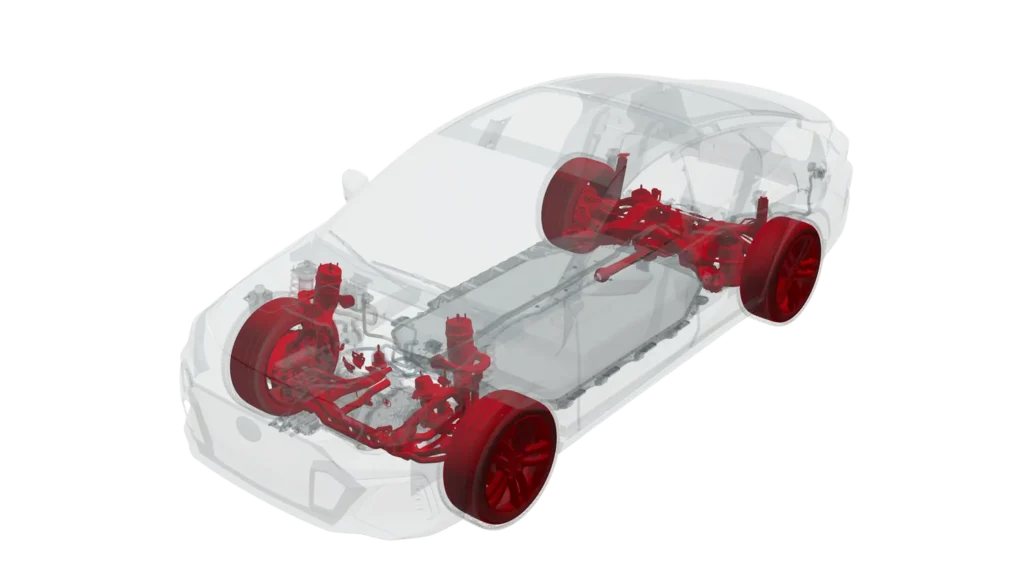

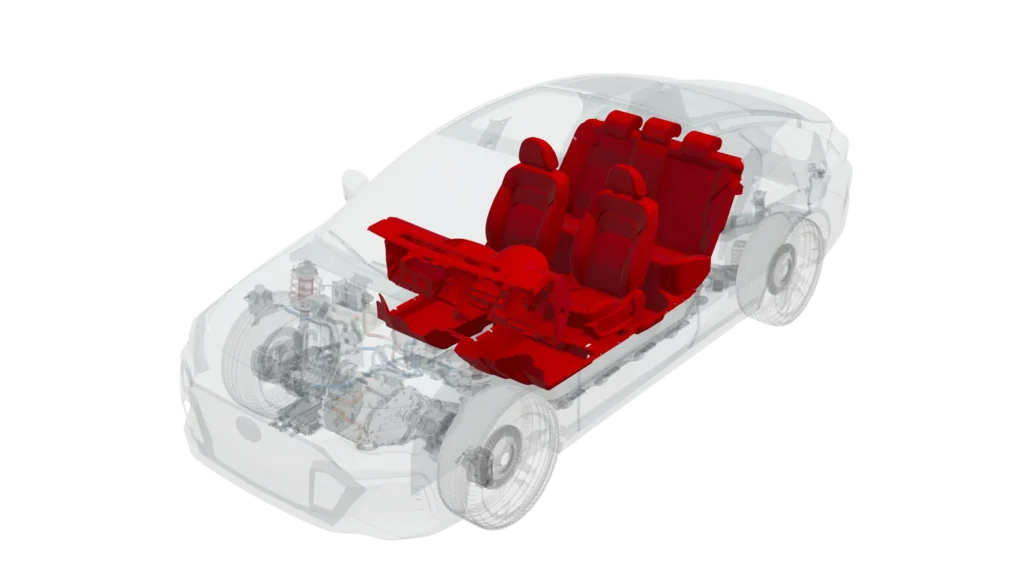

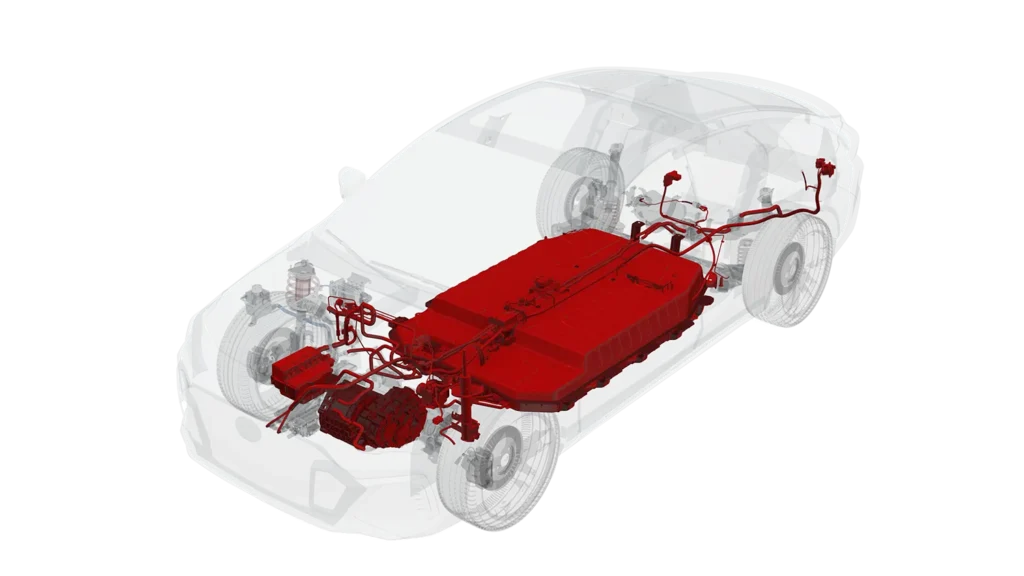

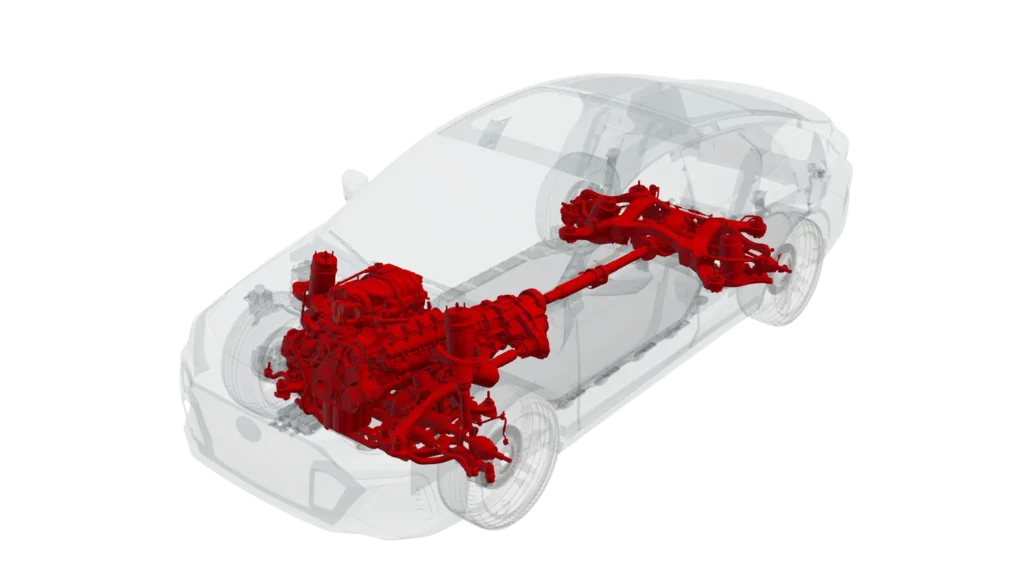

These parts are used in several fields of automotive applications:

- chassis

- seatings

- brakes and safety systems

- engine

- powertrain & driveline systems

These are products manufactured according to strict customer specifications.

Dedicated control plans during production and the ability to do 100% sorting before packaging guarantee the complete fulfilment of quality requirements.

Engineered components used in several automotive applications

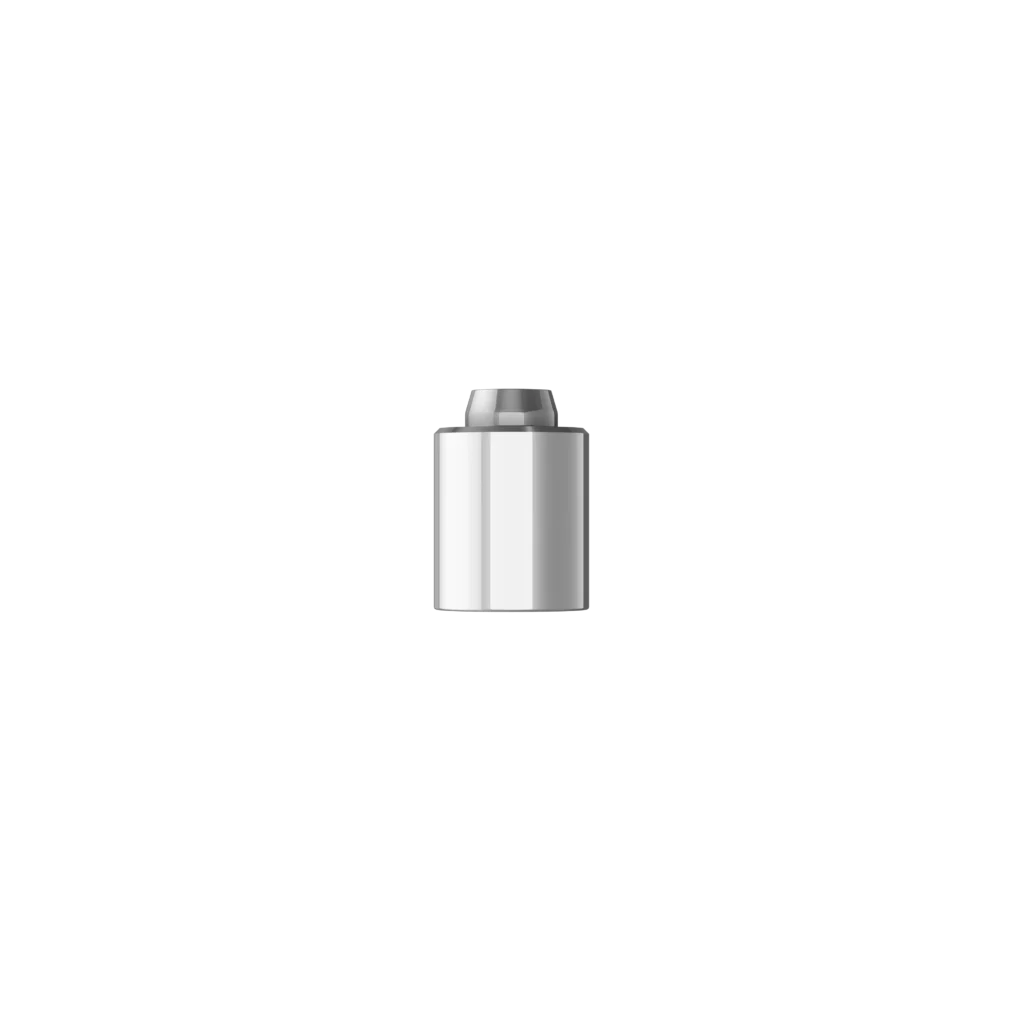

Bushing

Competencies

• Complex geometries realized just by forging

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Weldability

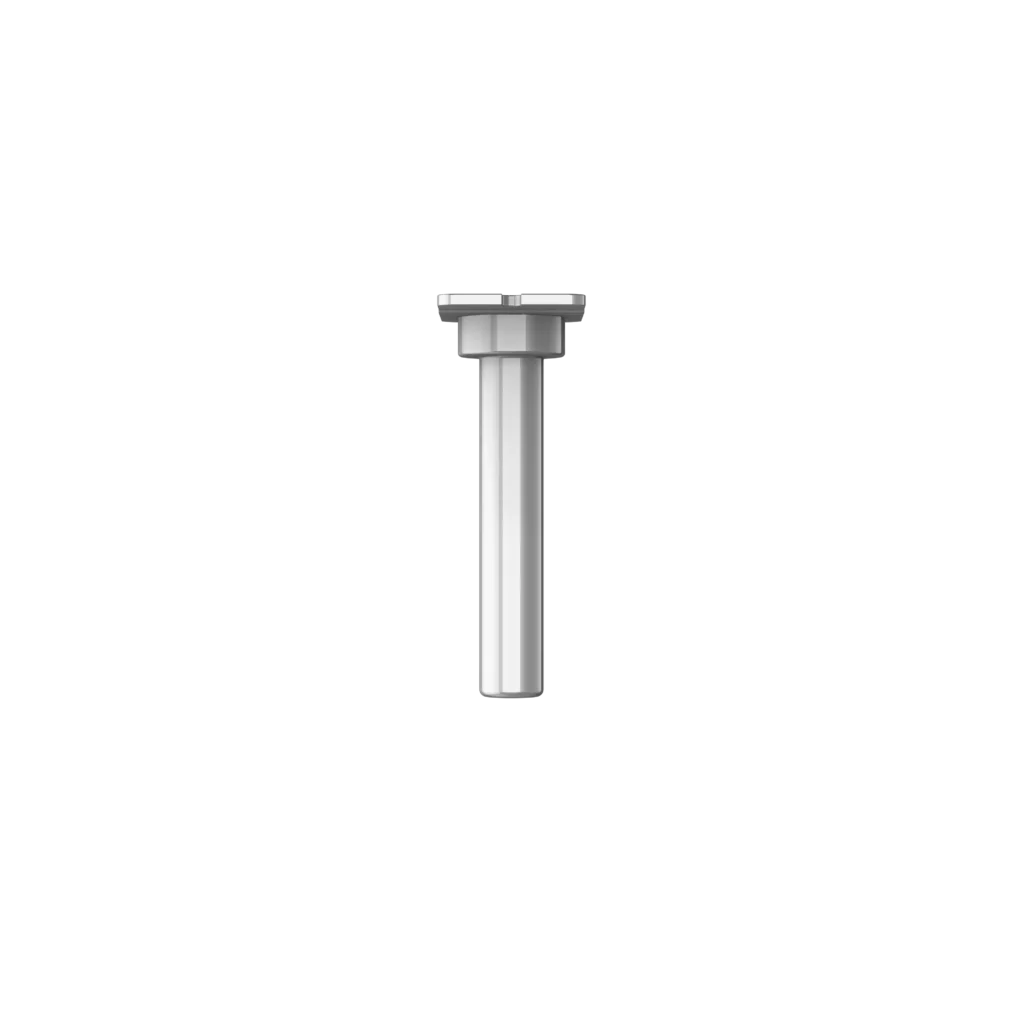

Welding Solutions

Competencies

• Complex geometries realized just by forging and assembly

• Geometry design suitable for welding process

• Great versatility for light weight approach

Main properties

• Size range according to customer needs

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to Heat Treated parts separately

• Weldability

• Coating : Blank or coating where needed

Applications

• Function as motherthread

• Avoid heavy chassis structures

• Welding

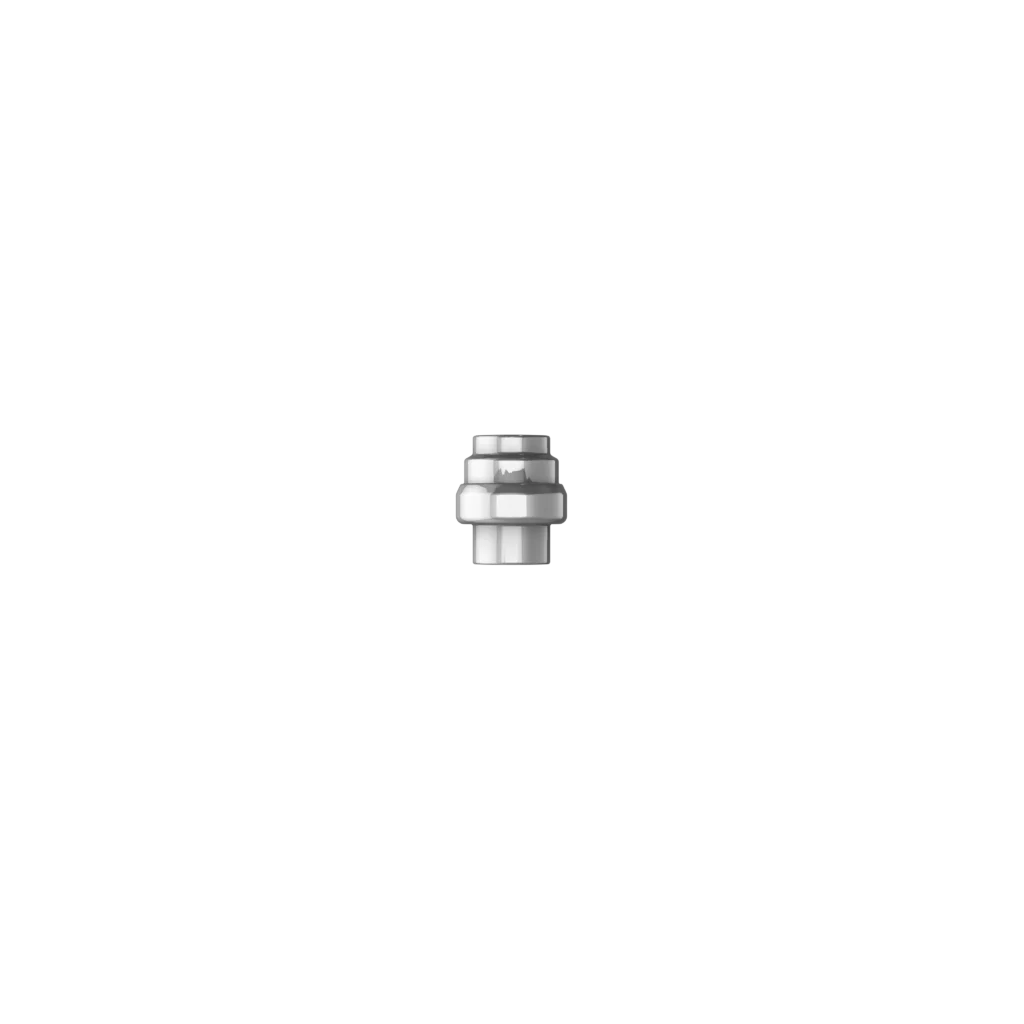

Complex Geometries

Competencies

• Complex geometries realized just by forging

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Other material (rubber) integration for final application

Engineered components used in several automotive applications

Bushing

Competencies

• Complex geometries realized just by forging

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Weldability

Welding Solutions

Competencies

• Complex geometries realized just by forging and assembly

• Geometry design suitable for welding process

• Great versatility for light weight approach

Main properties

• Size range according to customer needs

• Material: low carbon Steel, high strength Steel, Alu

• Possibility to Heat Treated parts separately

• Weldability

• Coating : Blank or coating where needed

Applications

• Function as motherthread

• Avoid heavy chassis structures

• Welding

Complex Geometries

Competencies

• Complex geometries realized just by forging

• Geometry design suitable for assembly and/or co-moulding process

• Economic competitiveness vs. machined solutions

Main properties

• Size range from up to Ø 50 mm

• Material: Steel, Alu

• Possibility to be Heat Treated

• Coating : ZnNi or ZnFlakes

Applications

• Joint reinforcement

• Compression limiter

• Other material (rubber) integration for final application

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.