We develop the best solution tailored to the customers needs, either independently or based on the provided customer design

Over time, Agrati has also specialized in the production of nuts.

Nearly 2 million nuts are produced each month, and over the years, all stages of the process have been perfected, from design to shipment, in order to ensure increasingly high standards of quality and safety, resulting in zero defects in the product.

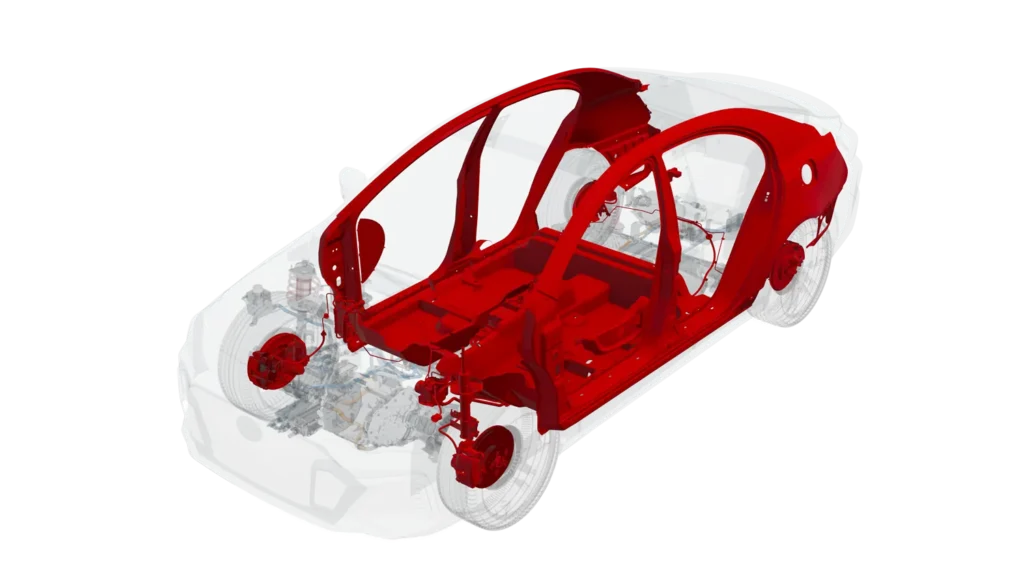

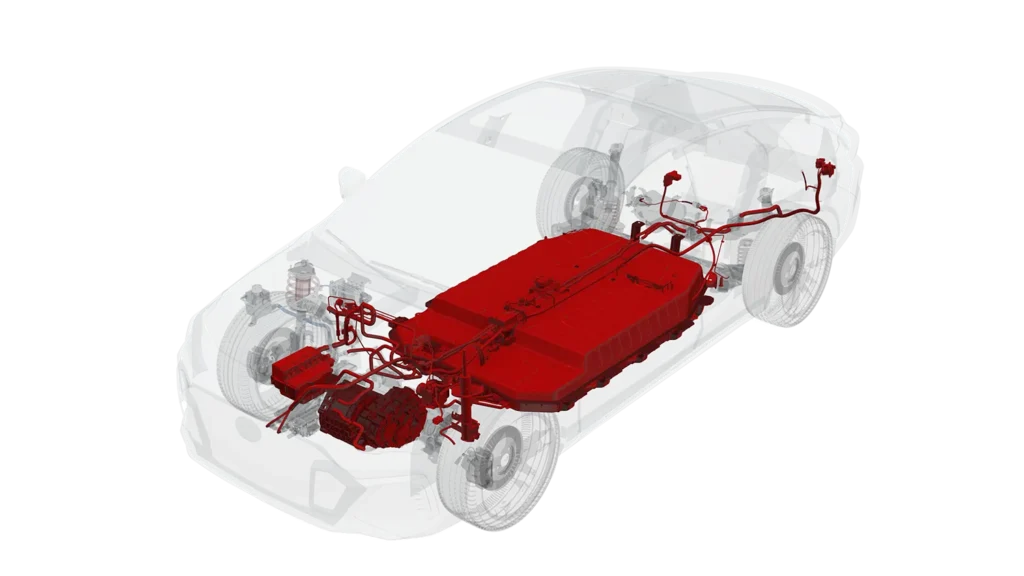

Engineered components used in several automotive applications

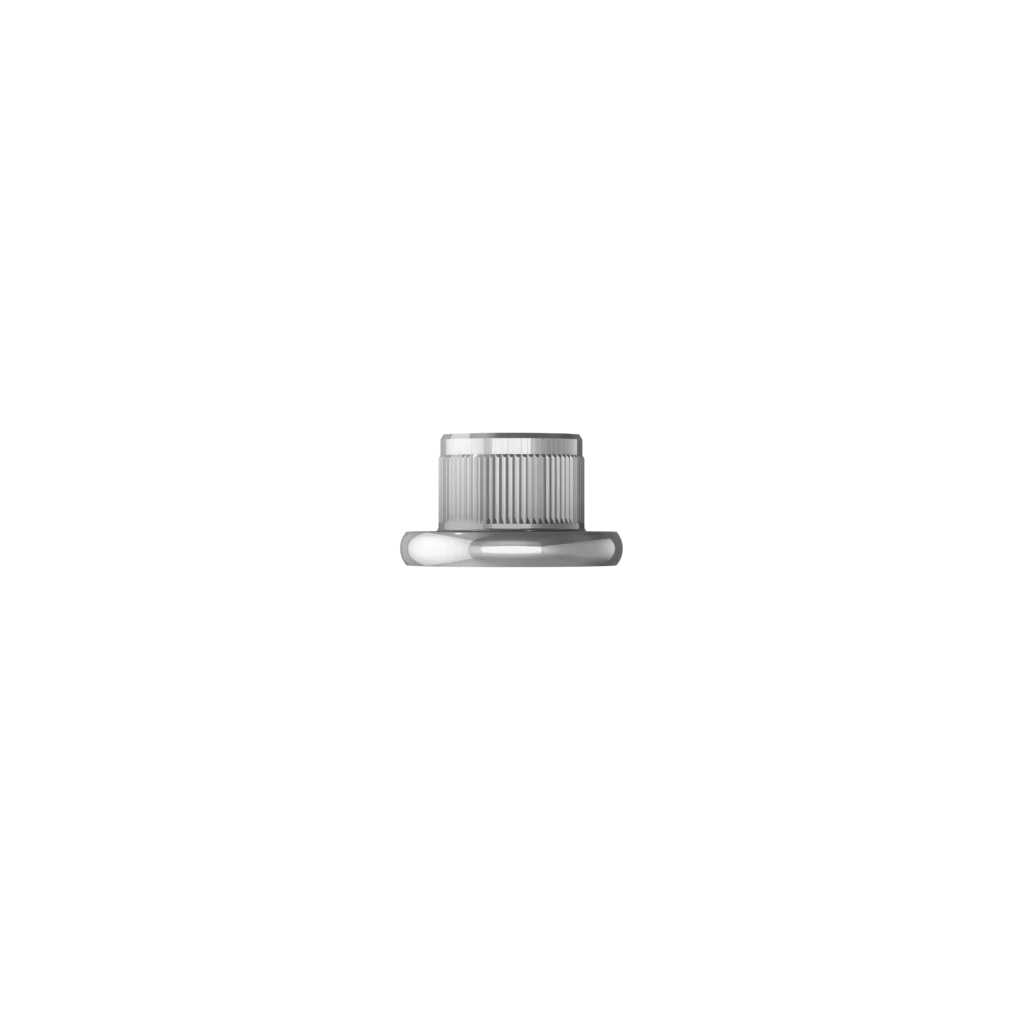

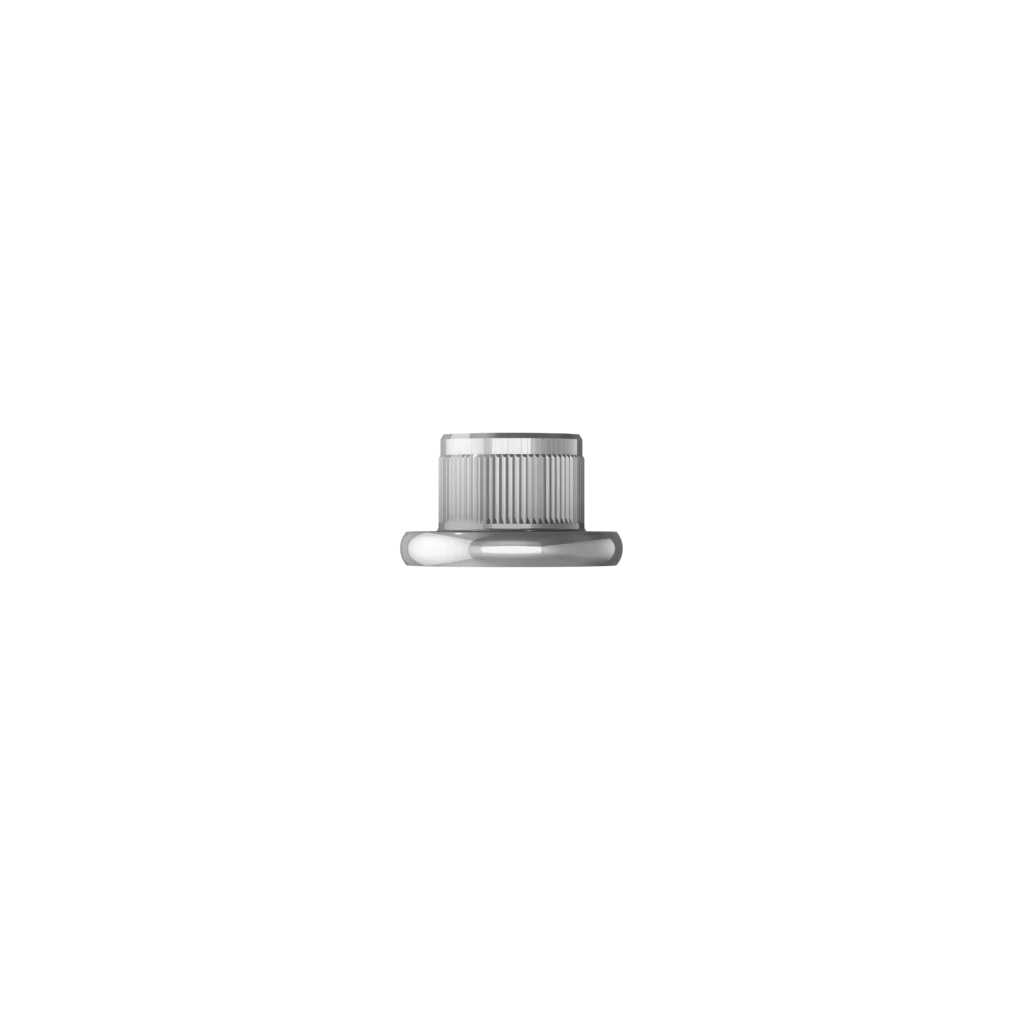

Threaded Insert

Competencies

• Knurling obtained by cold extrusion to ensure tighter tolerances, bringing to controlled interference levels with the aluminum counterpart

• Internal thread 100% mechanically controlled

• Controlled perpendicularity tolerance between the knurling feature / thread axis and the flange bearing surface

Main properties

•Size: M12 – M16

• Property class 8 – 10

• Insert to be pressed into the aluminum component

Applications

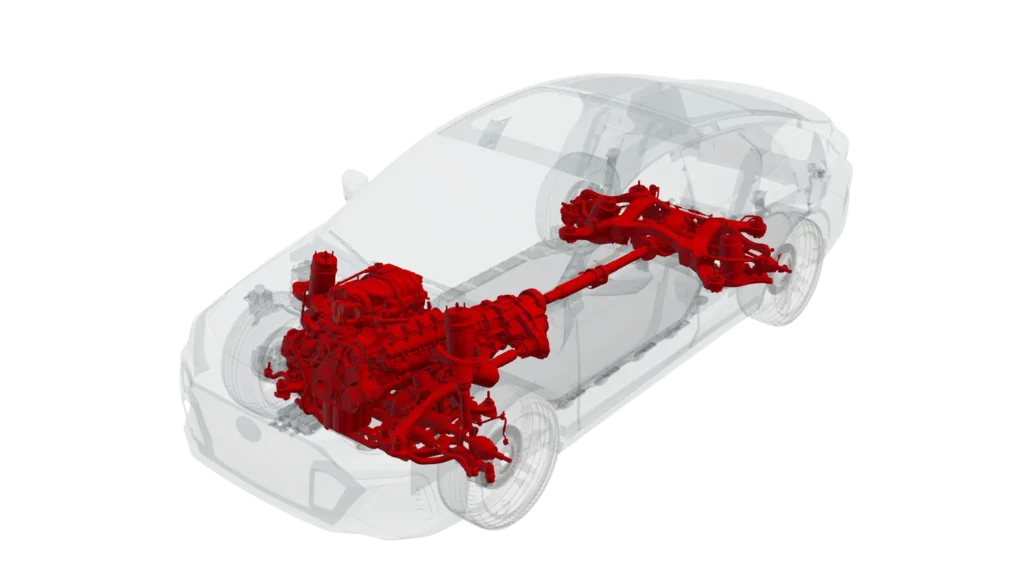

• Braking calipers

• Aluminum suspension components

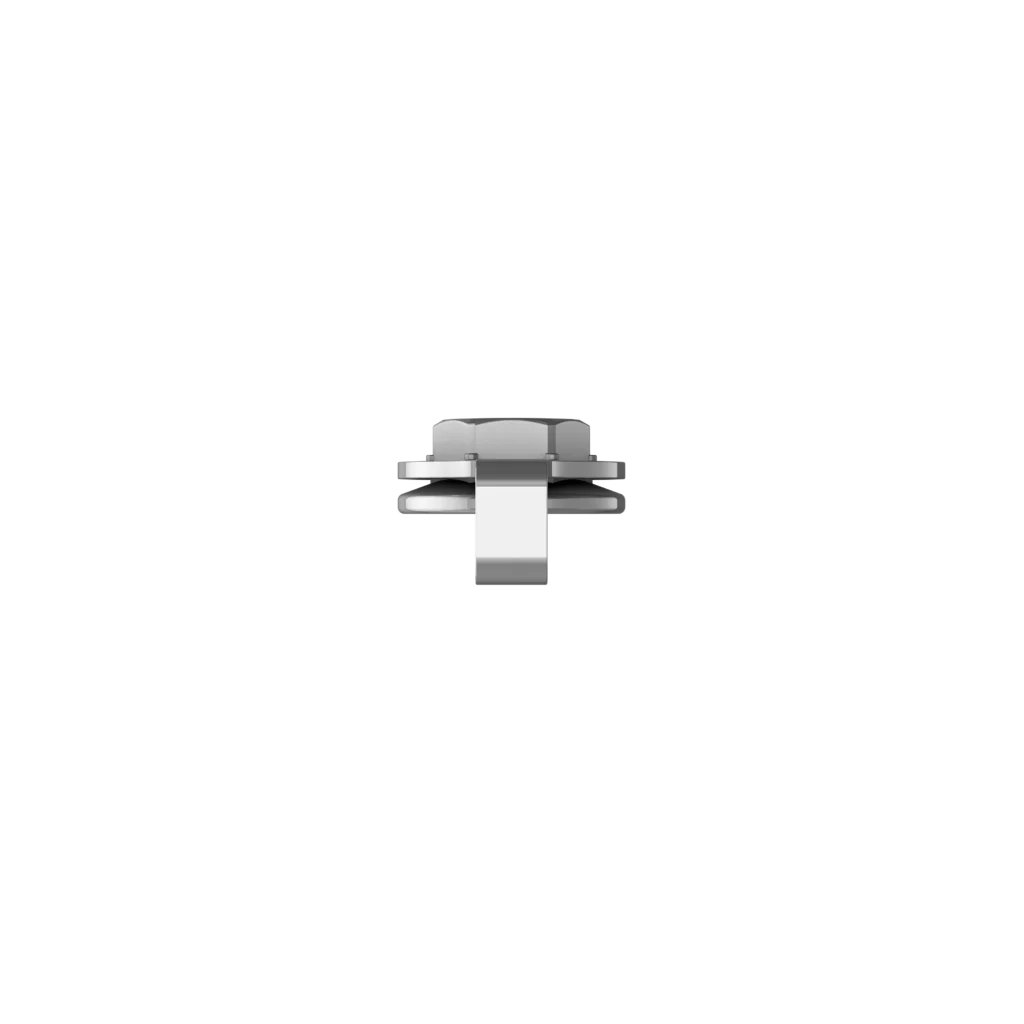

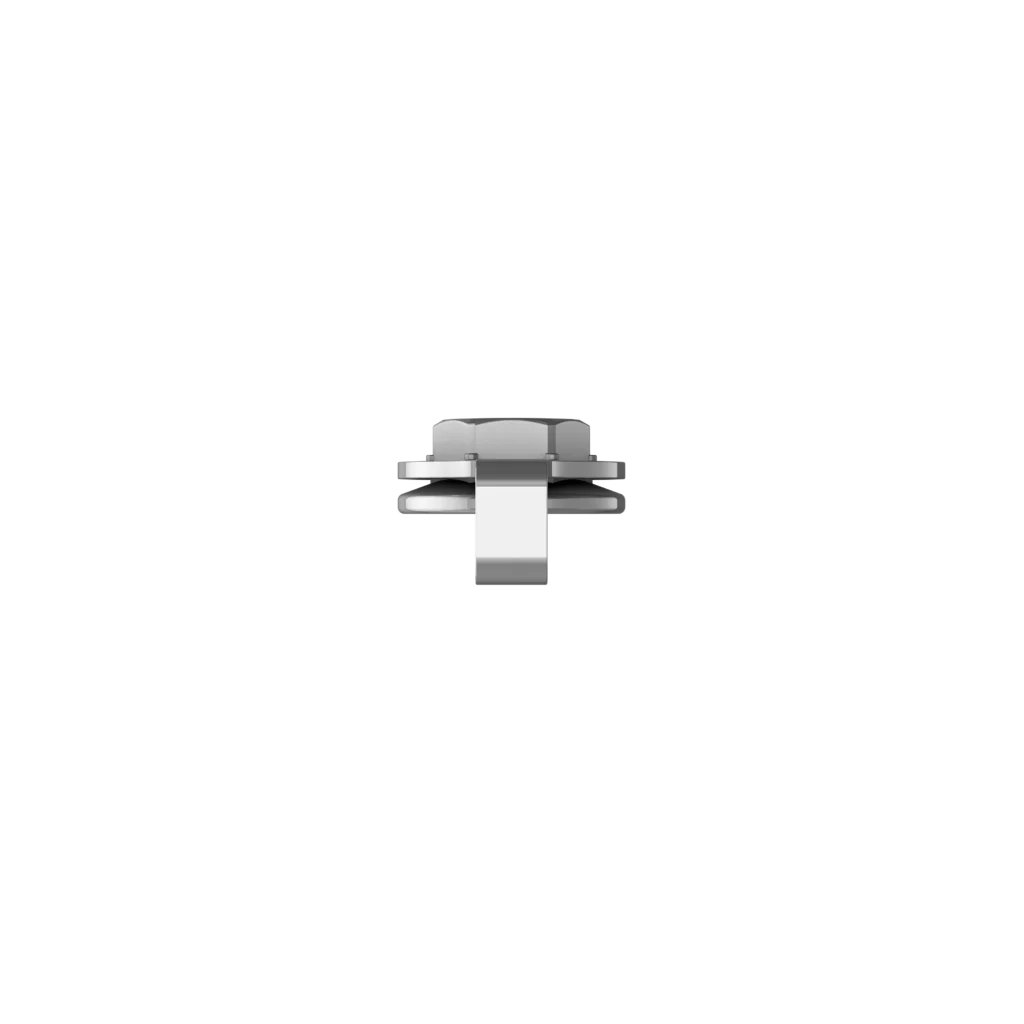

Flag Nut

Competencies

• The design of the sheet metal flag is customized in view of the specific counterpart

• Prevailing torque properties can be provided

Main properties

• Size: M6 – M20

• Anti-rotation effect of the nut

• Help the automatic assembly process

Applications

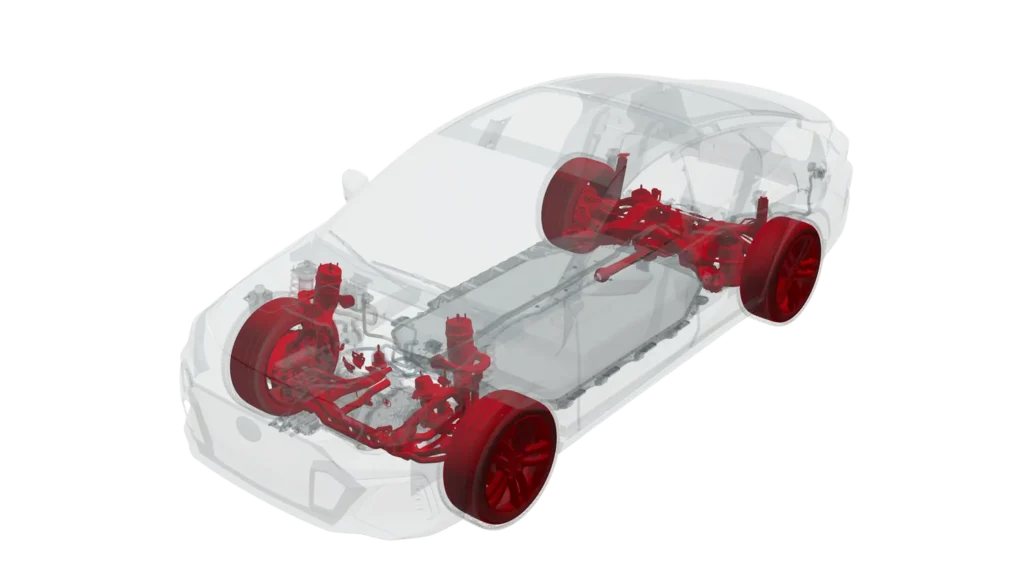

• Suspensions

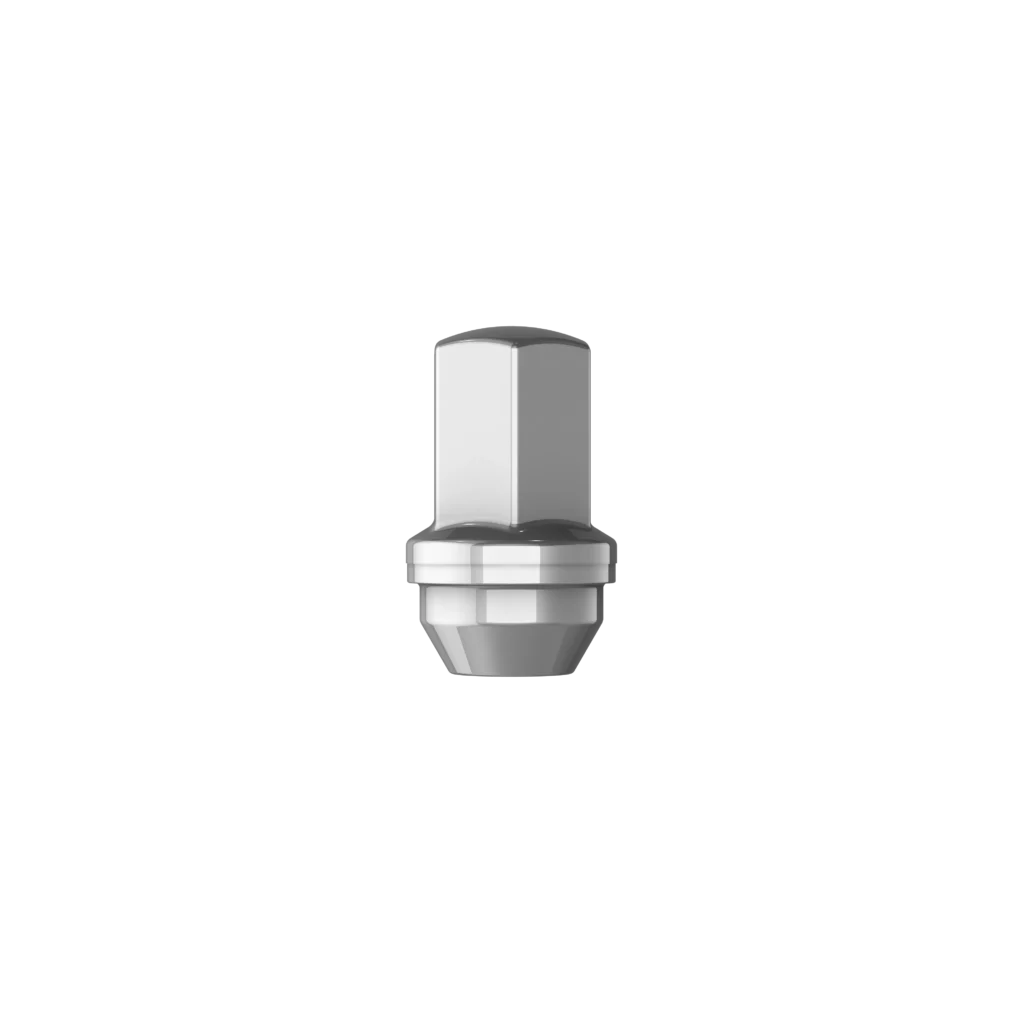

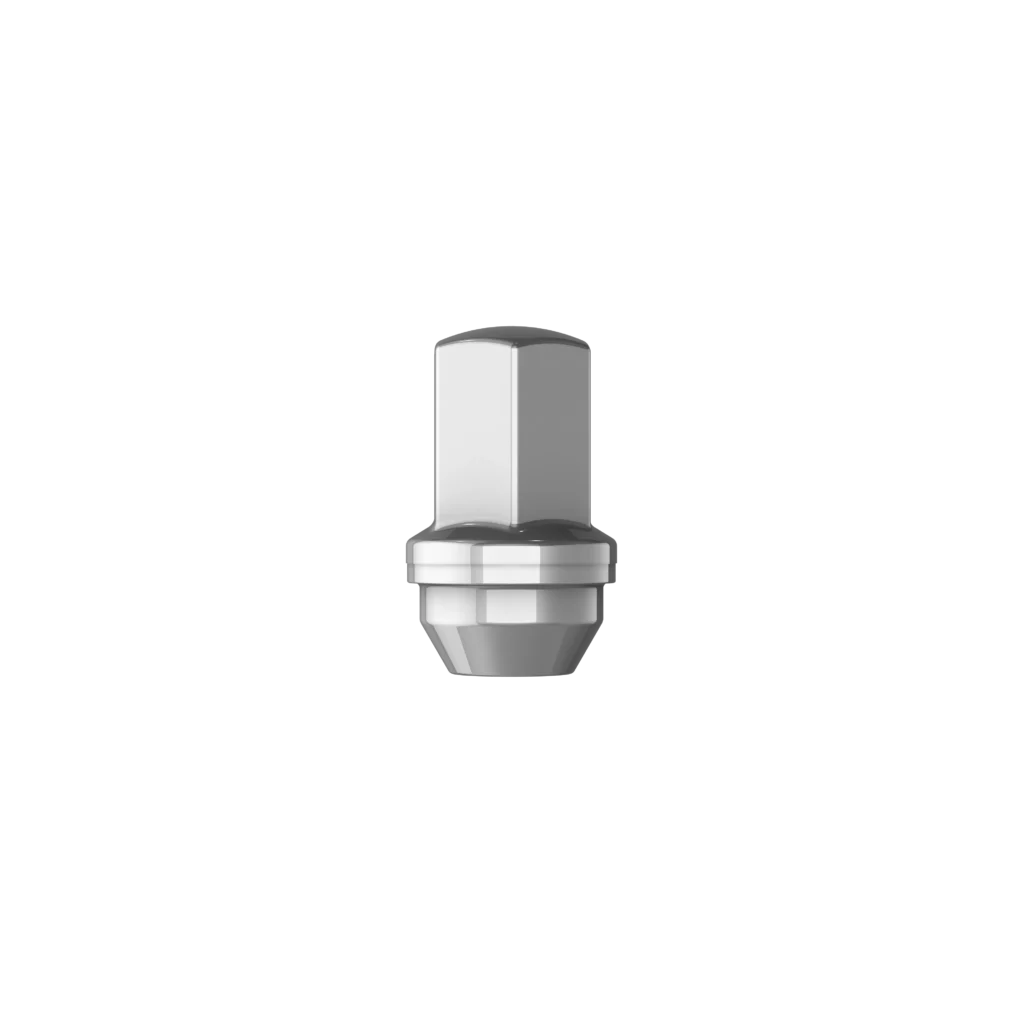

Wheel Nut

Competencies

• Different nut designs are available

• Stainless-steel caps can be assembled on the nuts, to ensure corrosion resistance and aesthetic functions

Main properties

• Size: M12-M14

• Property class: 8 – 9

• Watertightness of assembled stainless steel cap

Applications

• Fixations of wheel rims to hub

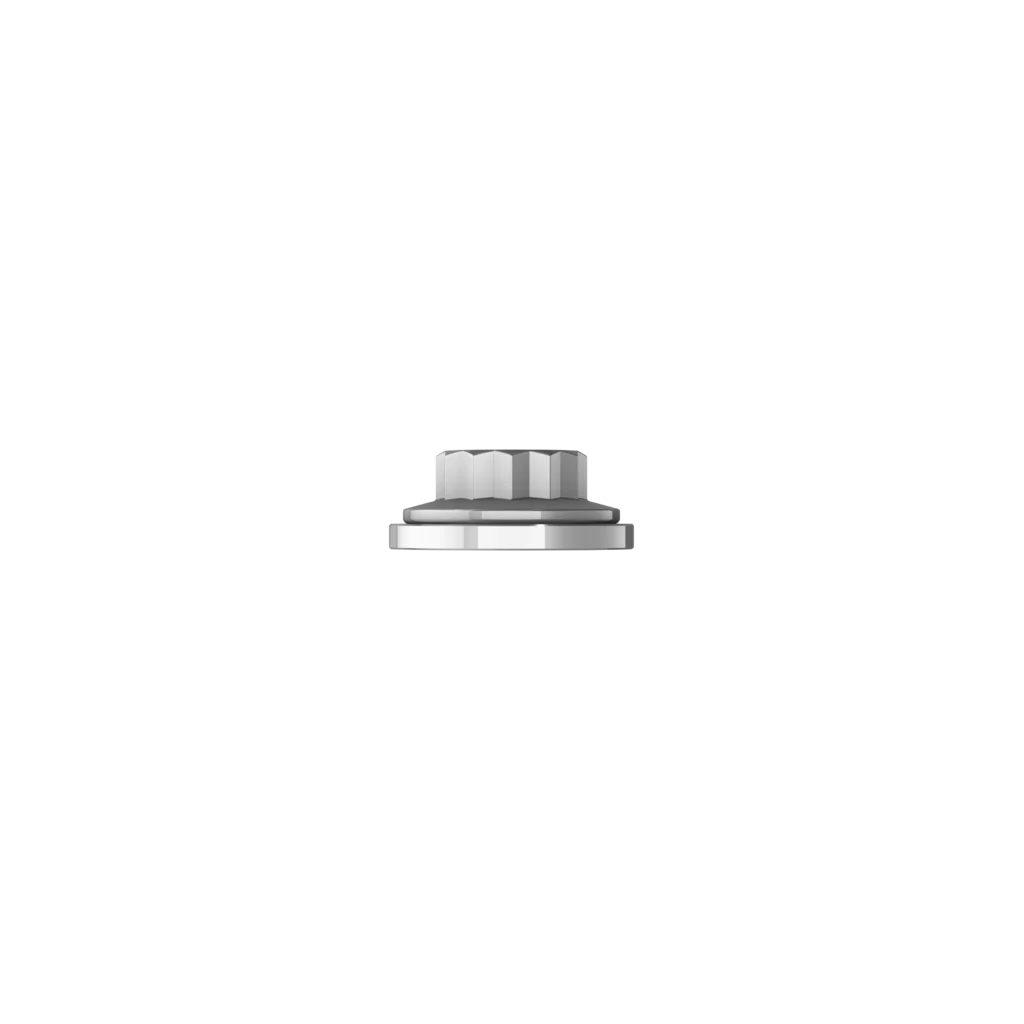

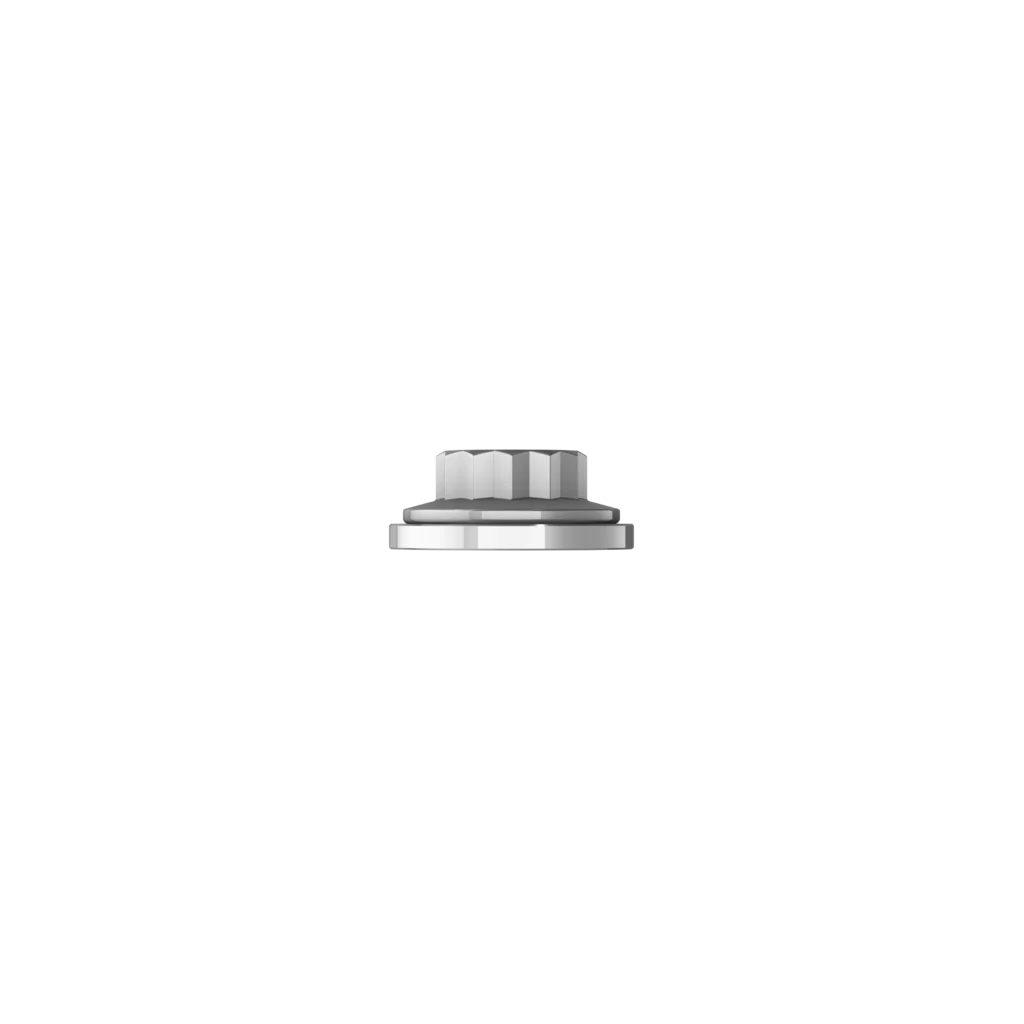

Chassis Nut

Competencies

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance and controlled friction coefficient

• Prevailing torque properties can be provided (nylon rings or metallic deformation)

• Products available with captive-washers too

• Lightweight design can be provided

Main properties

• Size: M5 – M20

• Property class 8 – 12

Applications

• Suspensions

• Steering system

Engineered components used in several automotive applications

Threaded Insert

Competencies

• Knurling obtained by cold extrusion to ensure tighter tolerances, bringing to controlled interference levels with the aluminum counterpart

• Internal thread 100% mechanically controlled

• Controlled perpendicularity tolerance between the knurling feature / thread axis and the flange bearing surface

Main properties

•Size: M12 – M16

• Property class 8 – 10

• Insert to be pressed into the aluminum component

Applications

• Braking calipers

• Aluminum suspension components

Flag Nut

Competencies

• The design of the sheet metal flag is customized in view of the specific counterpart

• Prevailing torque properties can be provided

Main properties

• Size: M6 – M20

• Anti-rotation effect of the nut

• Help the automatic assembly process

Applications

• Suspensions

Wheel Nut

Competencies

• Different nut designs are available

• Stainless-steel caps can be assembled on the nuts, to ensure corrosion resistance and aesthetic functions

Main properties

• Size: M12-M14

• Property class: 8 – 9

• Watertightness of assembled stainless steel cap

Applications

• Fixations of wheel rims to hub

Chassis Nut

Competencies

• Standardized or special drive styles can be designed

• Advanced coating systems to provide high corrosion resistance and controlled friction coefficient

• Prevailing torque properties can be provided (nylon rings or metallic deformation)

• Products available with captive-washers too

• Lightweight design can be provided

Main properties

• Size: M5 – M20

• Property class 8 – 12

Applications

• Suspensions

• Steering system

Are you looking for a Custom Solution?

Contact us to discover how we can support your product development and bring your fastening solutions to the next level.